Unloading method for grease multiple point central quantitative lubricating pipeline and self suction load device

A lubrication pipeline, multi-point technology, applied in the field of lubrication, can solve the problems of difficulty in filling grease, many branches, long unloading time, etc., to achieve short pipeline unloading time, expand application scope, and simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

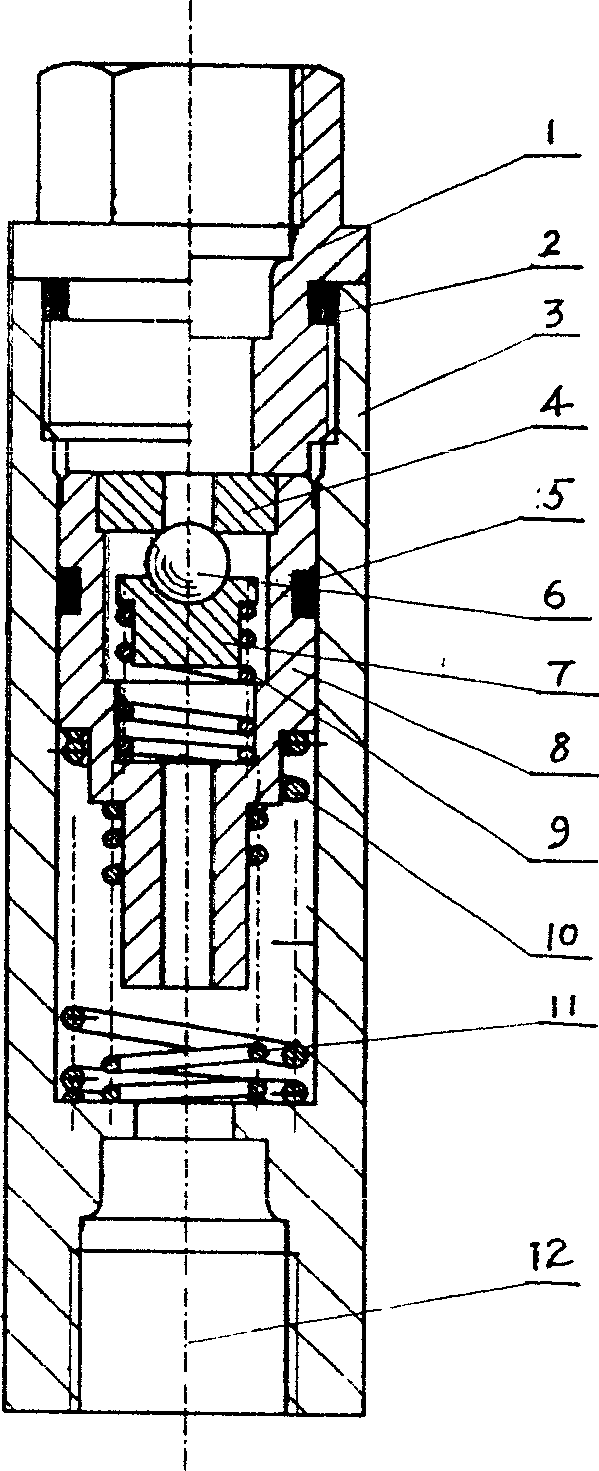

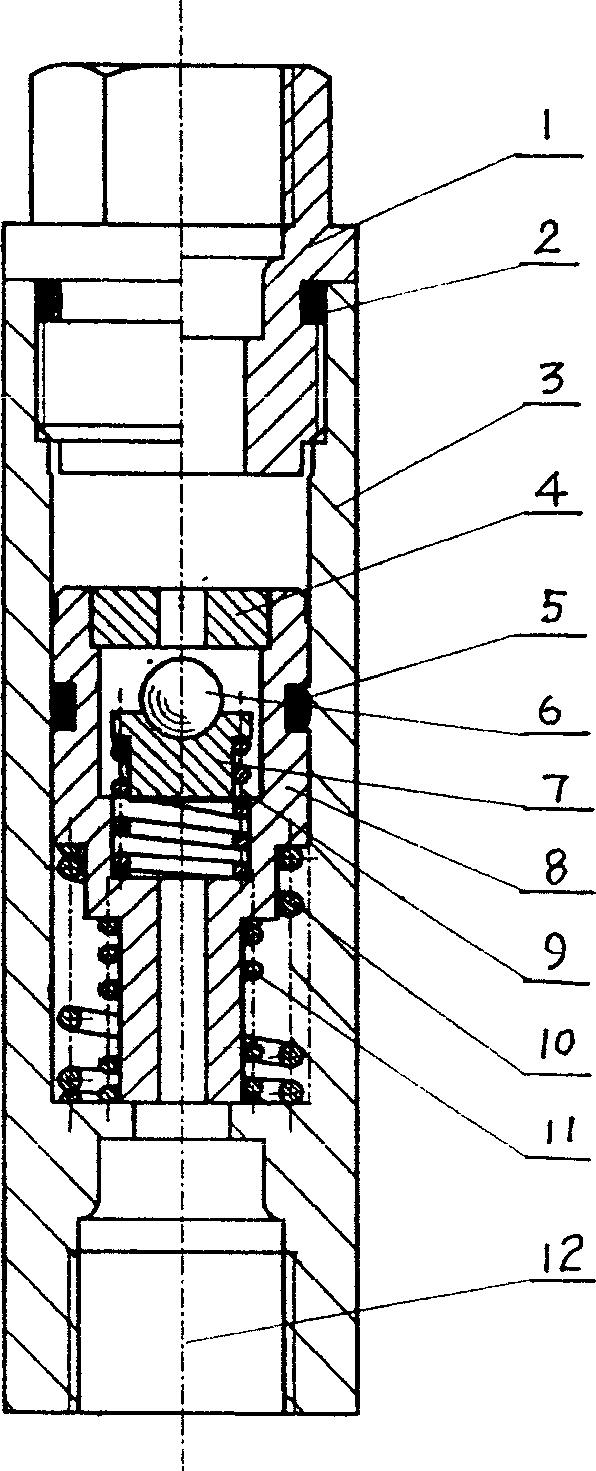

[0013] Depend on figure 1 and figure 2 As shown, an automatic load-absorbing device in a grease multi-point centralized quantitative lubrication pipeline of the present invention has a housing 3, one end of the housing is connected to a pipe joint 1, and a sealing ring 2 is arranged between the pipe joint and the housing. , the pipe joint is connected with the lubricating main oil supply pipeline, and the other end of the housing is provided with a pipe connection hole 12, which is connected to the pressure relief distributor through the pipeline; there is a piston 8 in the housing, and a seal is provided between the piston and the housing Ring 5, the piston can slide back and forth along the inner wall of the housing, a plug 4 with an oil hole is fixed at the end of the piston, and springs 10 and 11 are provided at the other end of the piston; one side of the plug can be connected with the pipe joint, and the other side There is a steel ball 6 facing the oil hole, the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com