Quick blank pipe type layering discharge device and quickly discharging method thereof

An unloading device, fast technology, used in packaging, transportation and packaging, transportation of passenger cars, etc., can solve problems such as large losses, blocked pipes, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

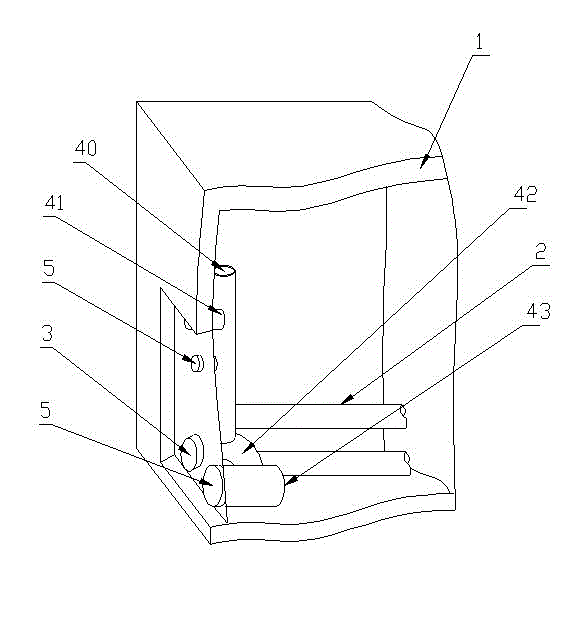

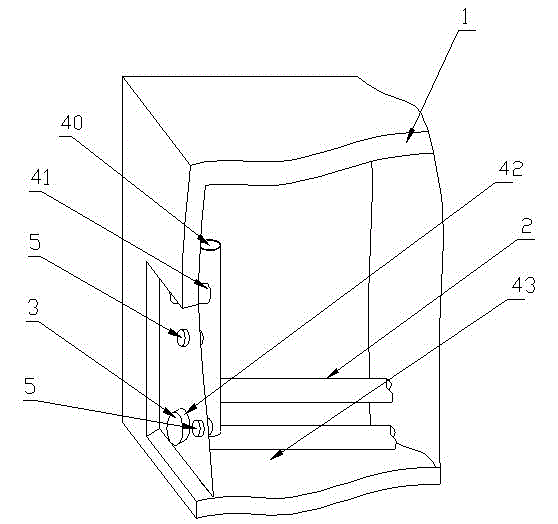

[0041] figure 1 Shown is a kind of empty pipe type layered rapid unloading device according to the present invention, comprising a container 1, the container 1 is provided with a discharge port 3; and is arranged in the container 1 and is located in the container 1 The heating device 2 at the bottom also includes a feed pipe, which communicates with the discharge port 3, and the feed pipe is sequentially provided with a plurality of discharge holes 41 from top to bottom, and at least one discharge hole is provided. The discharge holes 41 are located at the bottom of the container 1 ; and each of the discharge holes 41 is provided with an on-off control valve 5 . In this embodiment, the feed pipe is set to include a communication pipe 42 and a straight pipe 40, one end of the communication pipe 42 communicates with the discharge port 3, and the other end of the communication pipe 42 communicates with the discharge port at the bottom of the container. The hole 43 communicates; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com