Double-carriage self-discharging semitrailer

A semi-trailer and self-unloading technology, which is applied in the direction of inclined load-carrying vehicles, etc., can solve the problems of low loading and unloading efficiency, increased cost, accidental rollover of the lifting mechanism, etc., and achieves short unloading time, uniform force on the whole, The effect of preventing rollover accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

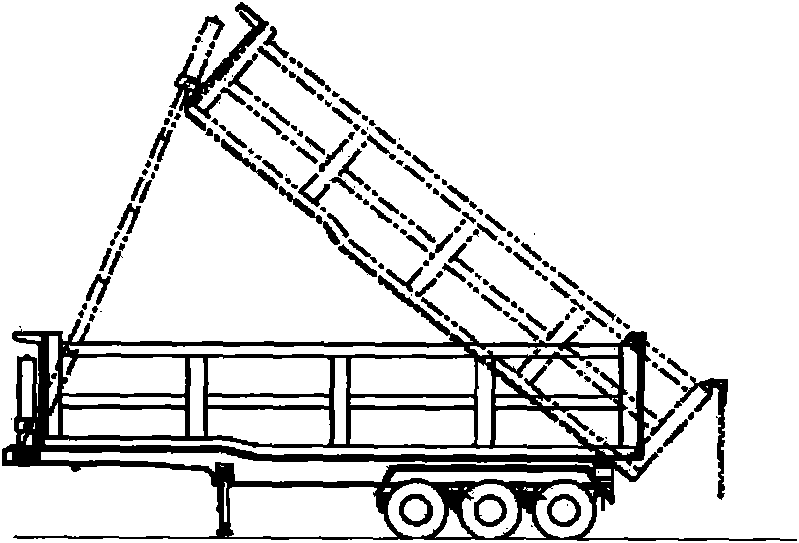

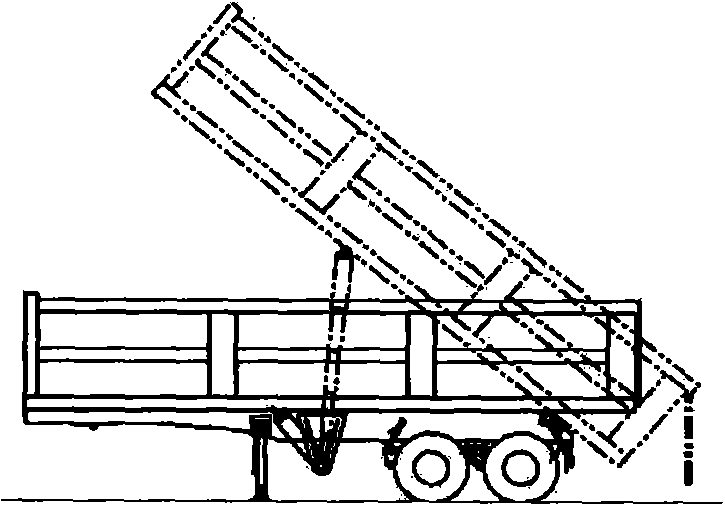

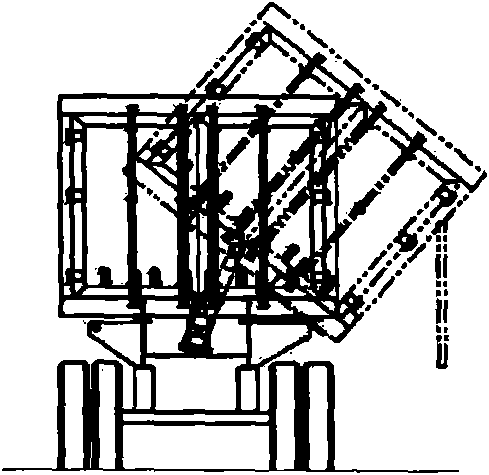

[0027] Such as Figure 4-8 As shown, the double-compartment dump semi-trailer is mainly composed of a vehicle frame 1, a supporting device 2, a wheel device 3, a front compartment 4, a rear compartment 5, a front compartment lifting mechanism 6 and a rear compartment lifting mechanism 7,

[0028] The front compartment 3 and the rear compartment 4 are installed on the vehicle frame 1, and are respectively driven by a combined lifting mechanism. The front compartment lifting mechanism 6 is a double-cylinder abdominal type, and unloads to the left and right bidirectional sides; the rear compartment lifting mechanism 7 is Single-cylinder forward push connecting rod combined rear unloading, and the hydraulic system of the front and rear compartment lifting mechanism is combined control;

[0029] The lifting mechanism 6 of the front carriage adopts a two-way side unloading method, and two sleeve-type single-acting oil cylinders are installed between the two longitudinal beams at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com