Unloading device for single mold tire vulcanizer

A tire vulcanization and single-mode technology, which is applied in the field of tire unloading devices of single-mode tire vulcanizers, can solve the problem that the tire unloading mechanism is difficult to meet the requirements, and achieve the effects of saving labor, improving work efficiency, and shortening tire unloading time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the embodiments shown in the drawings.

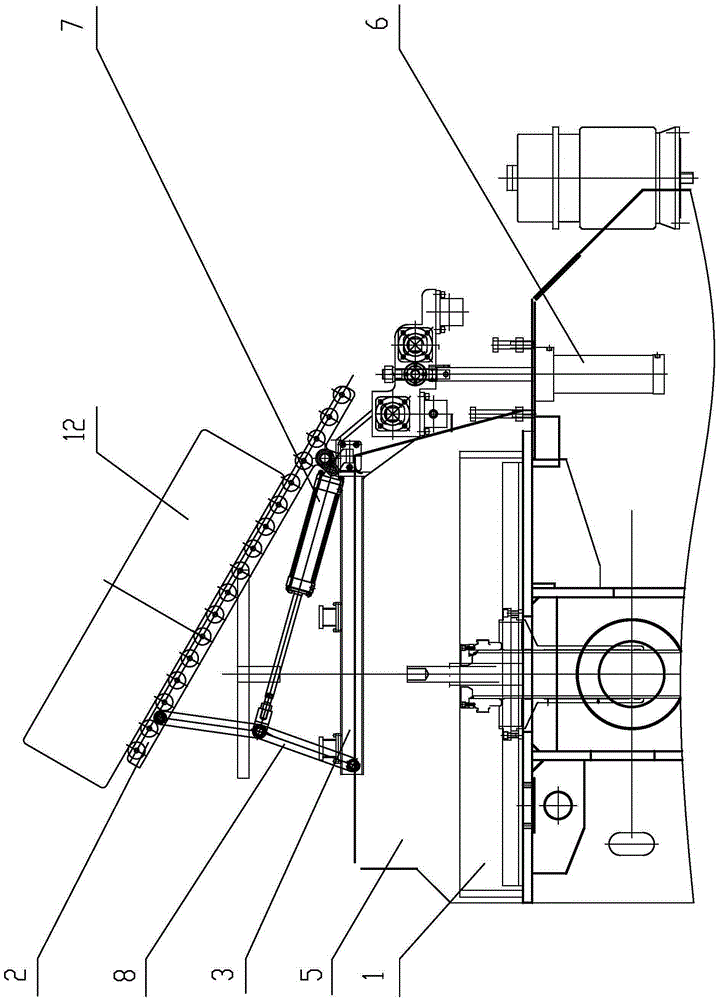

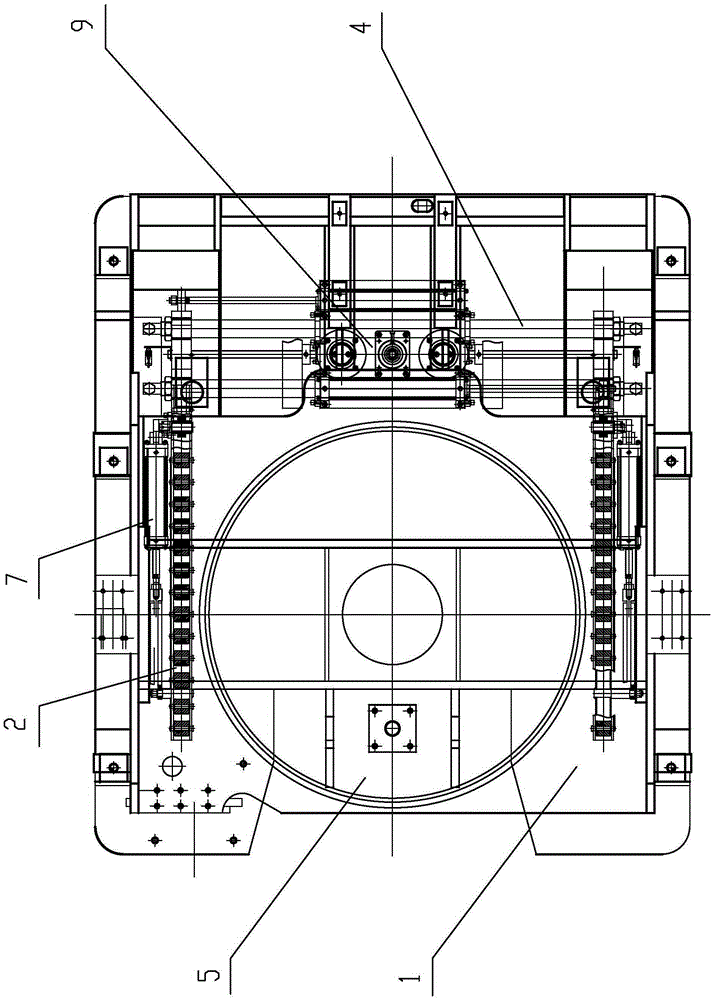

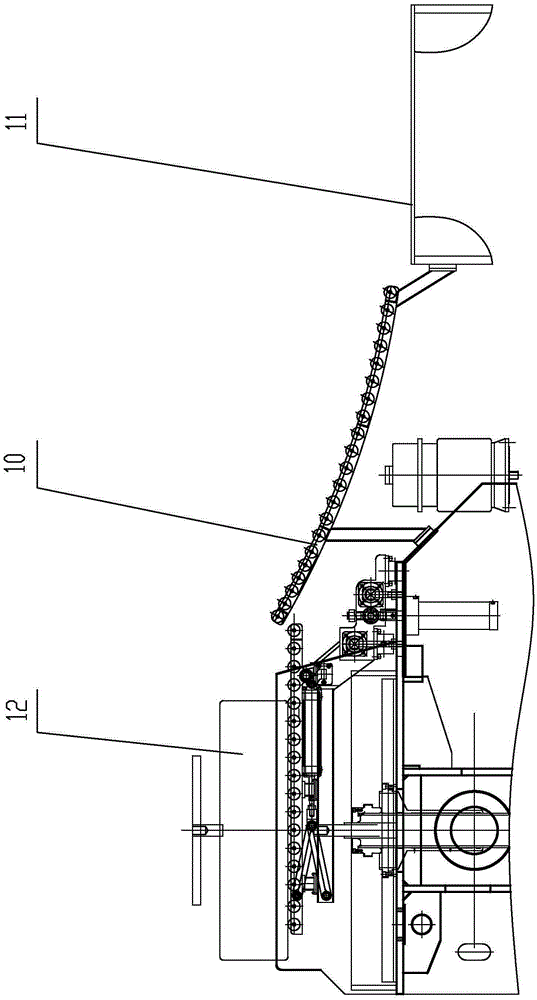

[0026] The tire unloading device of the single-mode tire vulcanizing machine of the present invention is mainly composed of a turning mechanism, an opening and closing mechanism, and a lifting mechanism. The lifting mechanism is arranged beside the steamer 5 behind the base 1 of the vulcanizing machine, and the opening and closing mechanism is arranged at On the lifting mechanism, the turning mechanism is arranged on the opening and closing mechanism.

[0027] The lifting mechanism adopts a lifting hydraulic cylinder 6 arranged on the base 1, and the piston rod of the lifting hydraulic cylinder 6 extends vertically upward, such as figure 1 Shown.

[0028] The opening and closing mechanism includes a sliding frame 4 and a telescopic assembly. The sliding frame 4 adopts two parallel horizontal sliding columns. The telescopic assembly adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com