Filtering method of sodium bichromate carbonizing liquid

A filtration method and a technology of sodium red alum, which are applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of unqualified quality of carbonized liquid and lower quality of sodium red alum, and achieve reduced chromium content, short unloading time, and good The effect of the filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

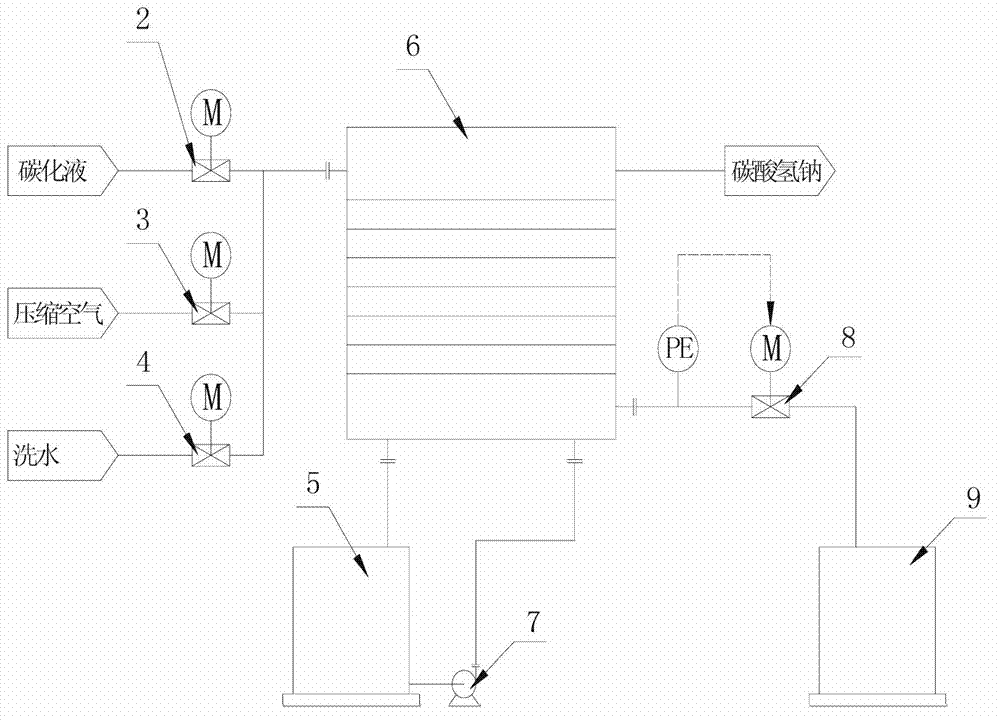

[0017] In a specific embodiment, the present invention specifically provides the following technical solutions:

[0018] First, the pressurized sodium red alum carbonized liquid enters the improved vertical plate and frame filter press through the feed pipe. The improvement of the vertical plate and frame filter press mainly lies in the addition of a pressure regulating valve, which prevents the carbonized liquid from backflowing and reduces the filtration efficiency when the pressure is released by the filter press. Under the control of the filtrate pressure regulating valve, the filtration process is always maintained at a predetermined pressure. When the pressure in the vertical plate and frame filter press exceeds the predetermined pressure, the filtrate flows to the filtrate storage tank through the filtrate output pipe; when the pressure at the inlet end rises, the feed regulating valve set on the feed pipe is automatically closed, and the setting The filtrate pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com