End-yarn insertion device

A technology of inserting device and end yarn, which is applied in the direction of clothing, apparel, textiles and papermaking, etc., which can solve problems such as insufficient yarn tension, excess yarn tension, loose knitting yarn, etc., to prevent grip damage and prevent the number of parts from increasing , The effect of preventing the deviation of clamping timing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

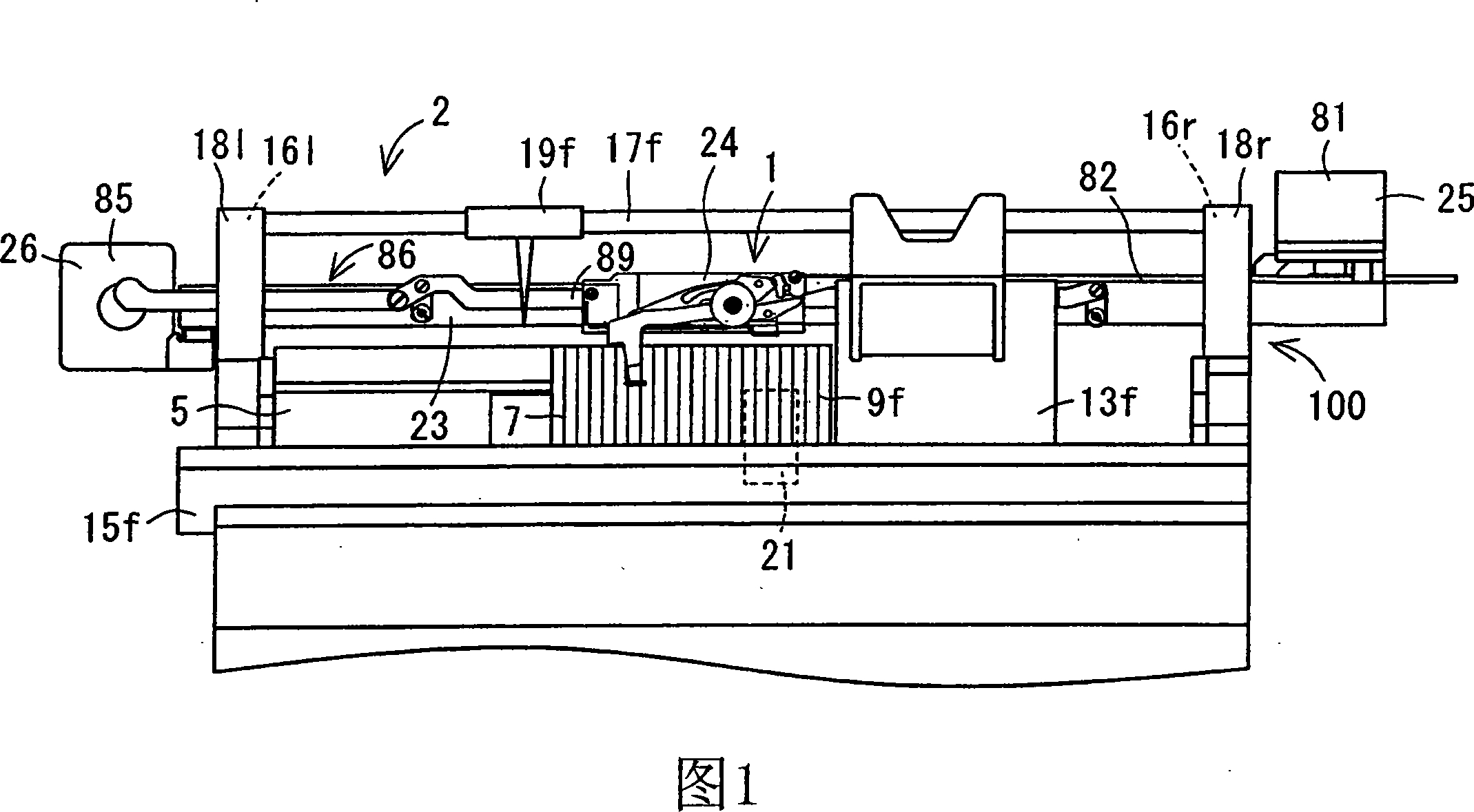

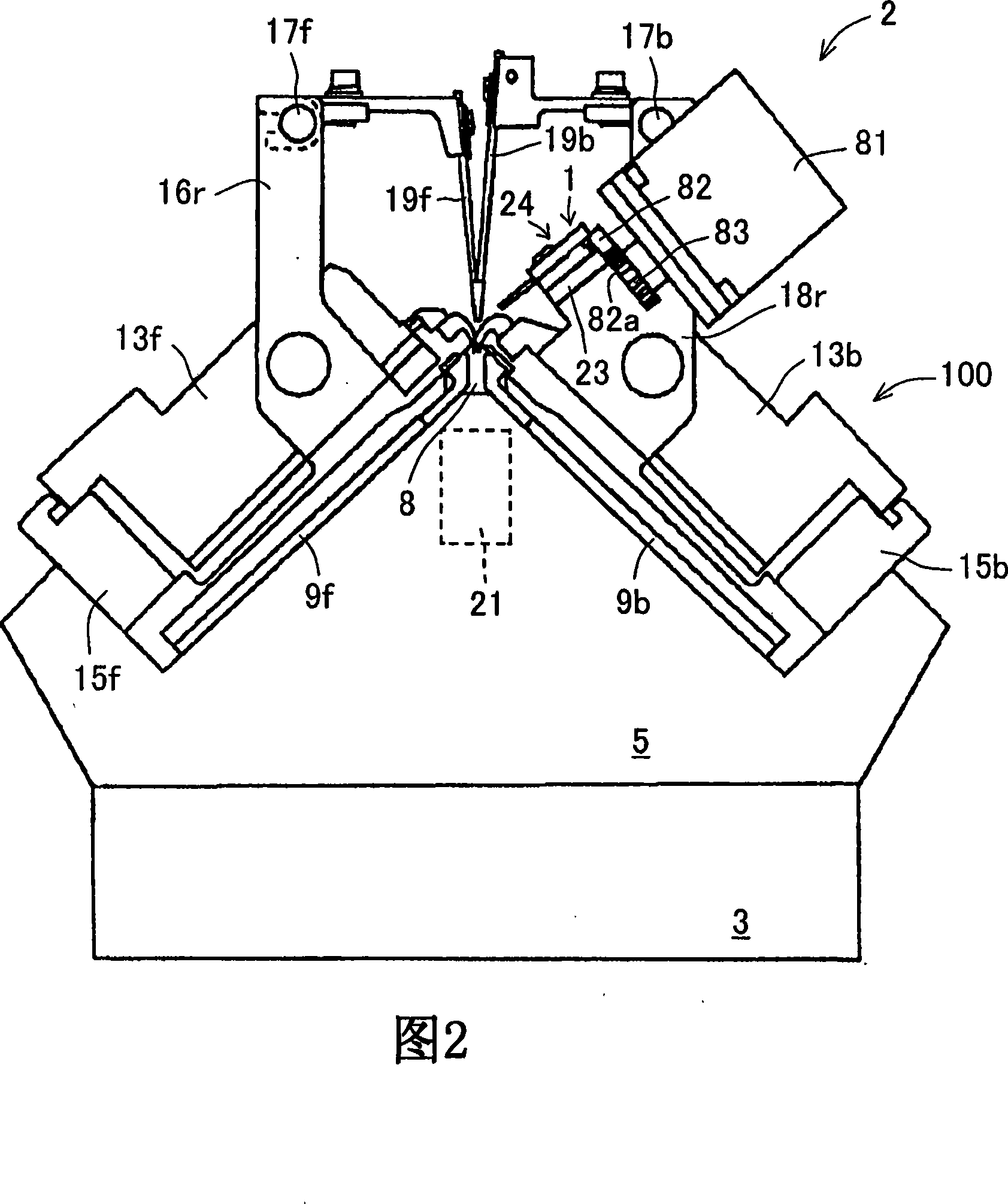

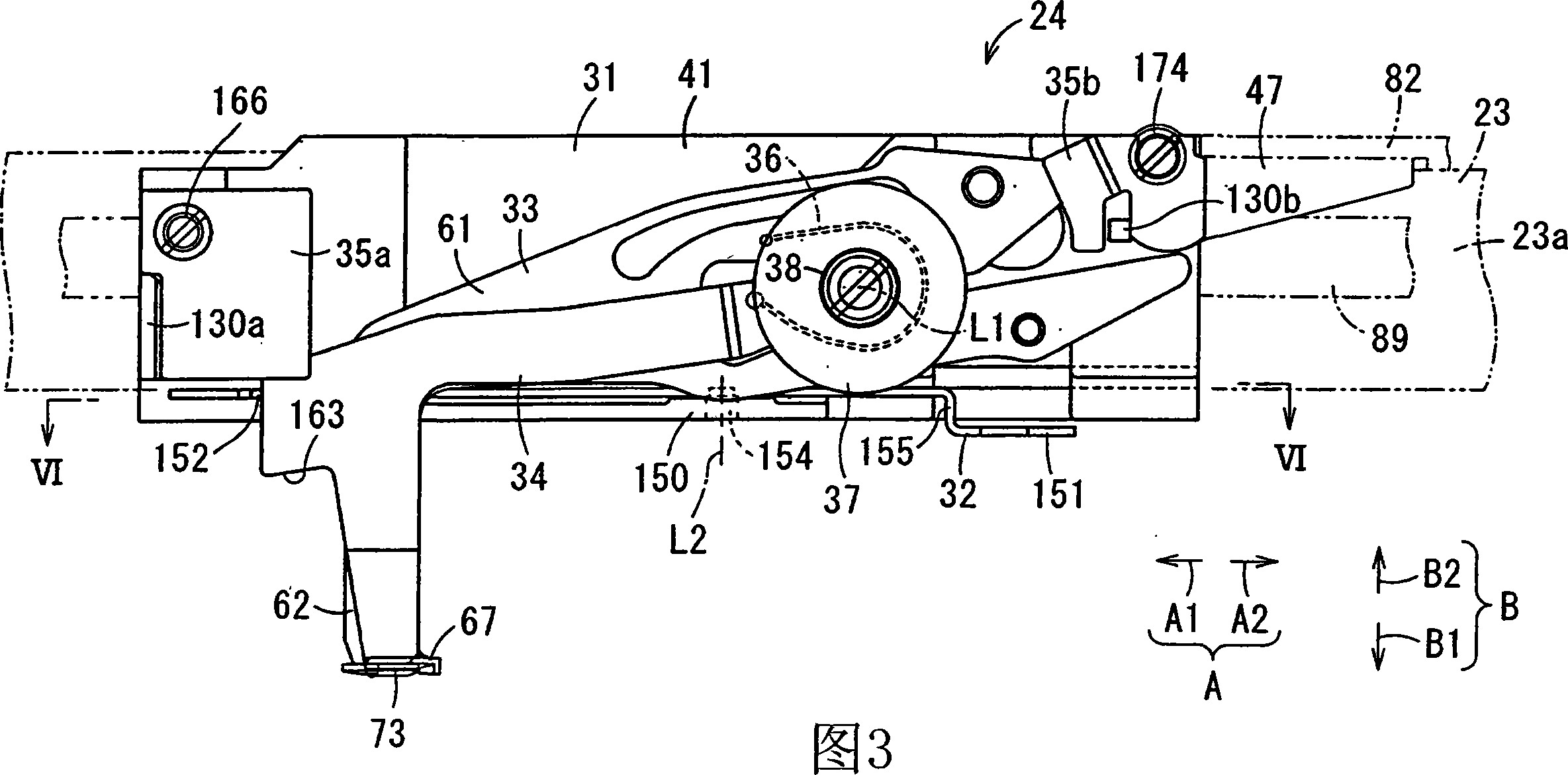

[0022] Hereinafter, embodiments for carrying out the present invention will be described with reference to the drawings. Fig. 1 is a front view showing a glove knitting machine 2 having an end yarn insertion device 1 as one embodiment of the present invention. FIG. 2 is a side view showing the glove knitting machine 2 . The glove knitting machine 2, which is a type of flat knitting machine, includes a knitting machine main body 100 for knitting knitted fabrics, a cutting holding device 21, and an end yarn inserting device 1 .

[0023] The knitting machine main body 100 has a pair of chassis 3 provided facing each other, and a mountain-shaped support stand 5 extending along both ends of the pair of chassis 3 in the left-right direction and protruding upward is provided. On the support table 5, a pair of front and rear needle beds 9f, 9b extending in the left-right direction are provided so as to accommodate the plurality of knitting needles 7 freely. A pair of front and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com