Textile machine

A technology of textile machinery and spindle, which is applied in the field of textile machinery, and can solve the problems of larger bending angle, limitation of yarn types, and higher height of machine base, etc., and achieve the effects of restraining tension changes, easy maintenance, and good maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] best practice

[0037] The false twist processing machine 1 which is one embodiment of the textile machine of this invention is demonstrated using drawing.

[0038] First, the overall structure of the false twisting machine 1 will be described with reference to the drawings.

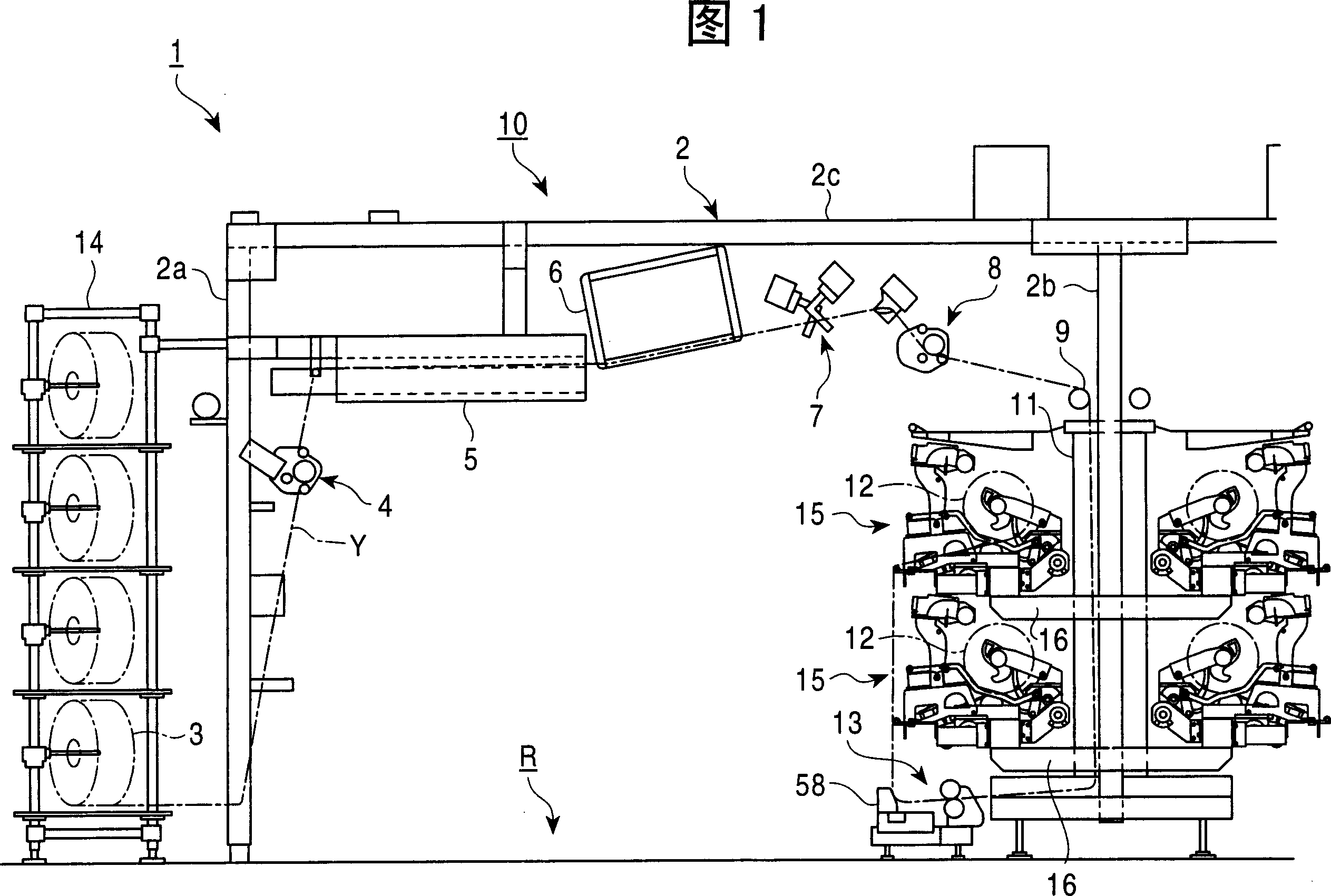

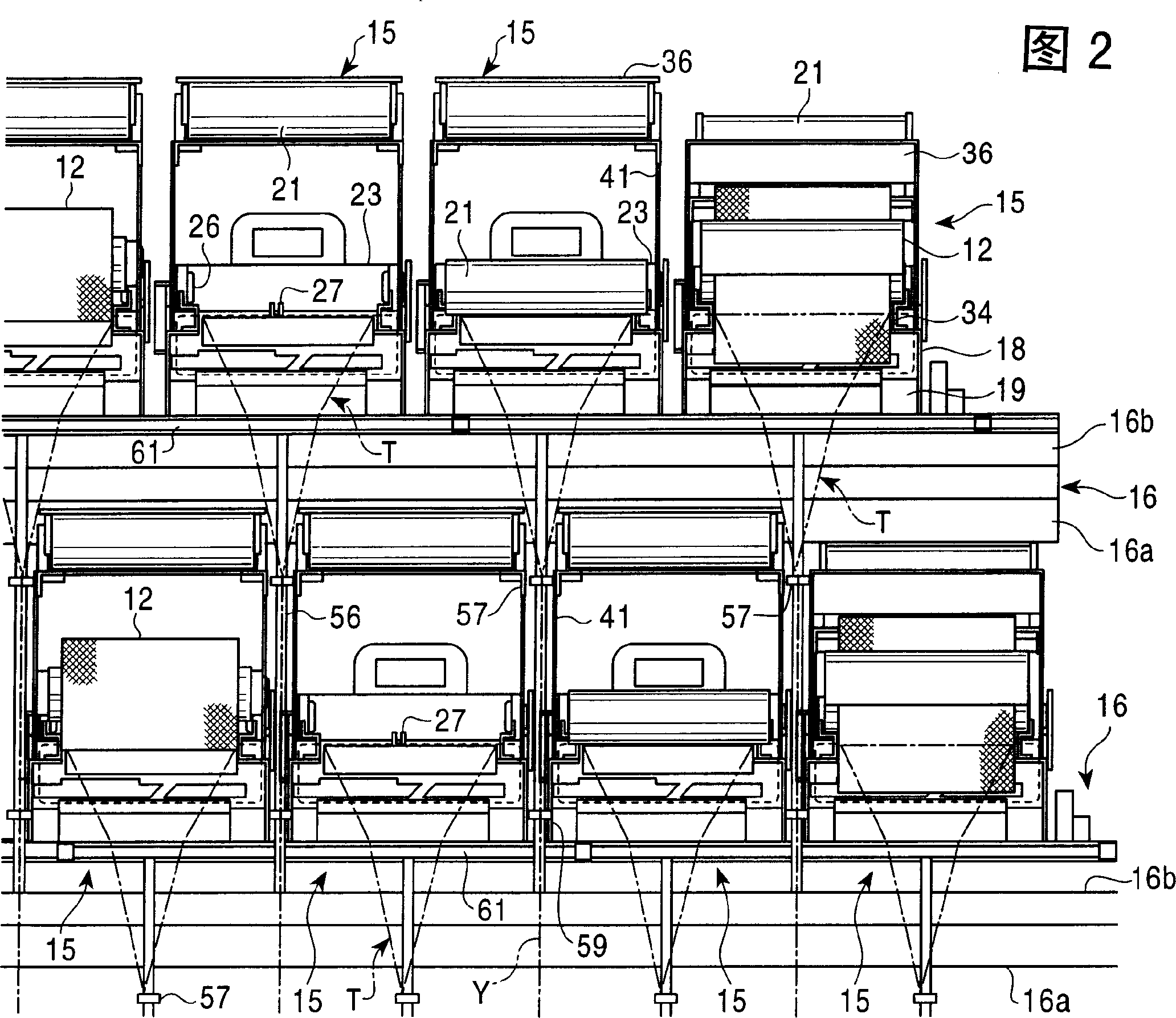

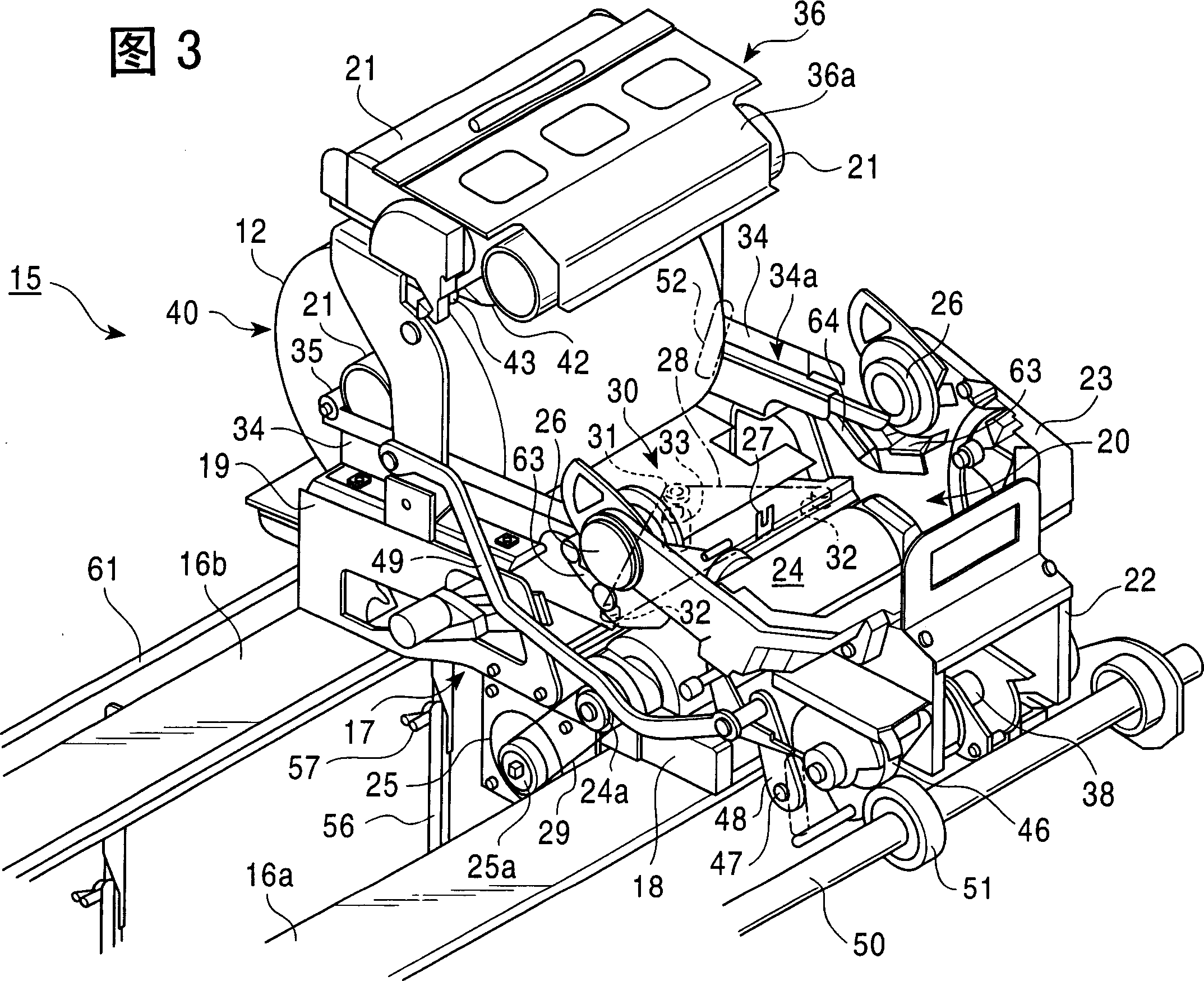

[0039] As shown in FIG. 1 , a false twist processing machine 1 is constituted by a plurality of spindles 10 arranged in parallel in the vertical direction of the drawing, and each spindle 10 is supported by a frame 2 of the false twist processing machine 1 .

[0040] The stand 2 surrounds a working channel R provided along the parallel arrangement direction of the spindles 10 . The stand 2 includes a pair of upright frames 2a, 2b opposed to each other in the horizontal direction across the working passage R, and a connecting frame 2c connecting the upper ends of the upright frames 2a, 2b.

[0041] The spindle 10 is a device that heats a sliver (hereinafter referred to as “yarn”) Y drawn from one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com