Wire-cut electric discharge machine

An EDM wire and cutting machine technology, which is used in electrode manufacturing, electric machining equipment, metal processing equipment, etc., can solve the problems such as the inability to obtain the linearity of tension fluctuation suppression, the inability to suppress large wire tension fluctuations, and the difficulty in suppressing characteristics. , to achieve the effect of easy installation and maintenance, good linearity, and adjustment and suppression characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

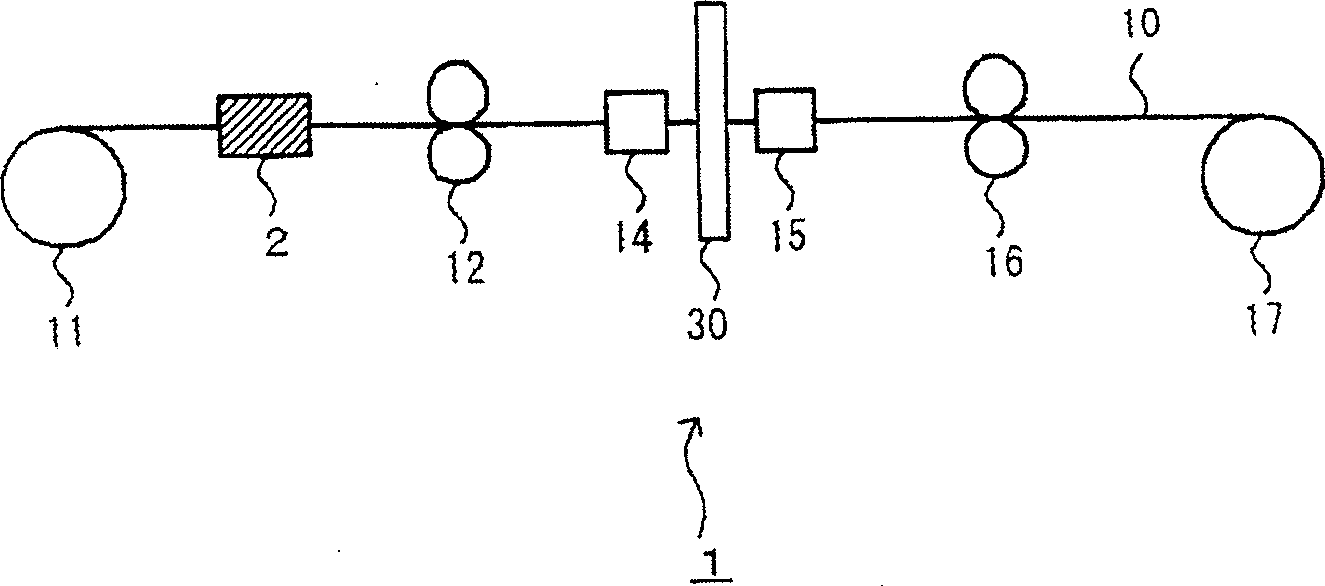

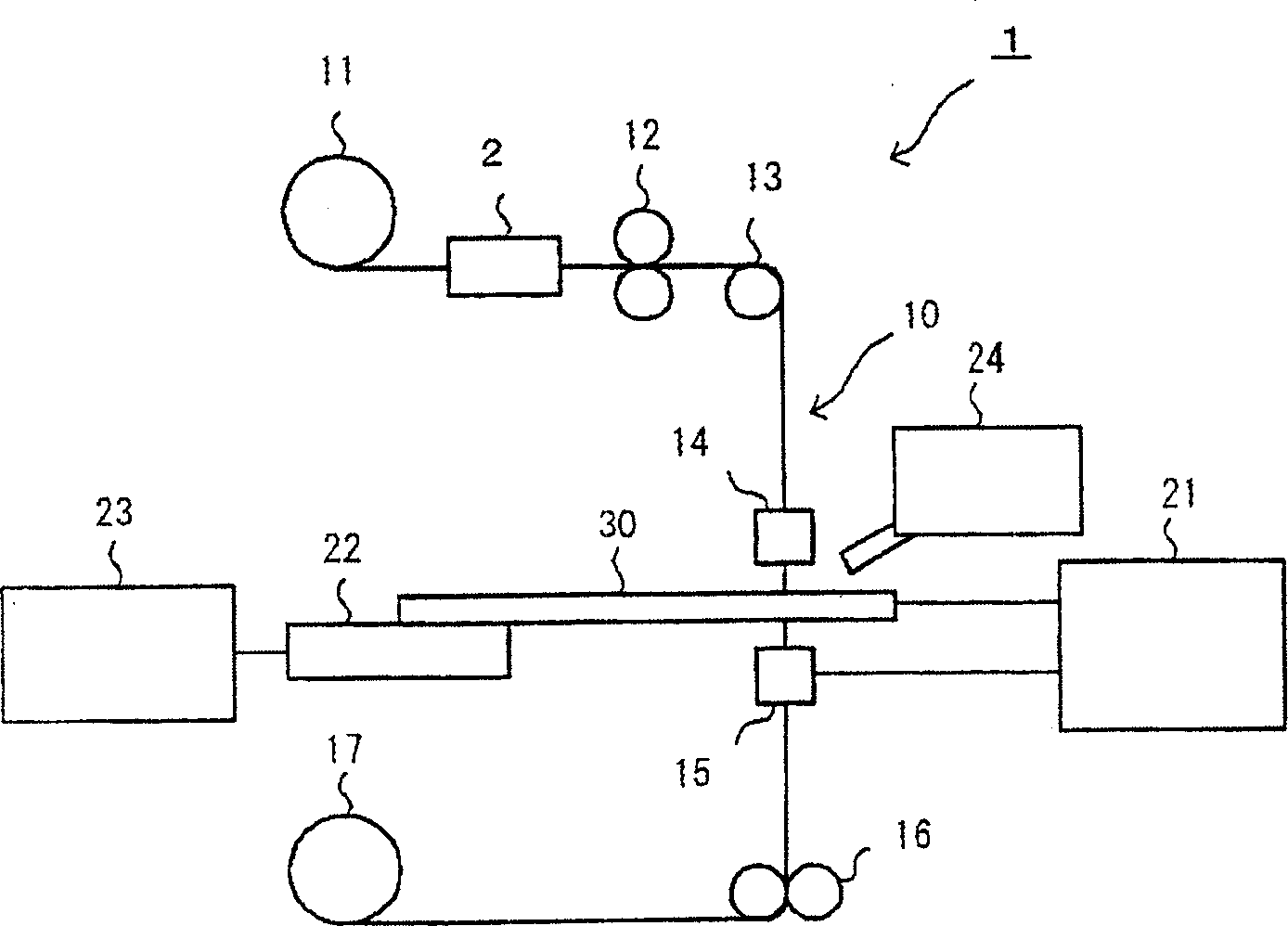

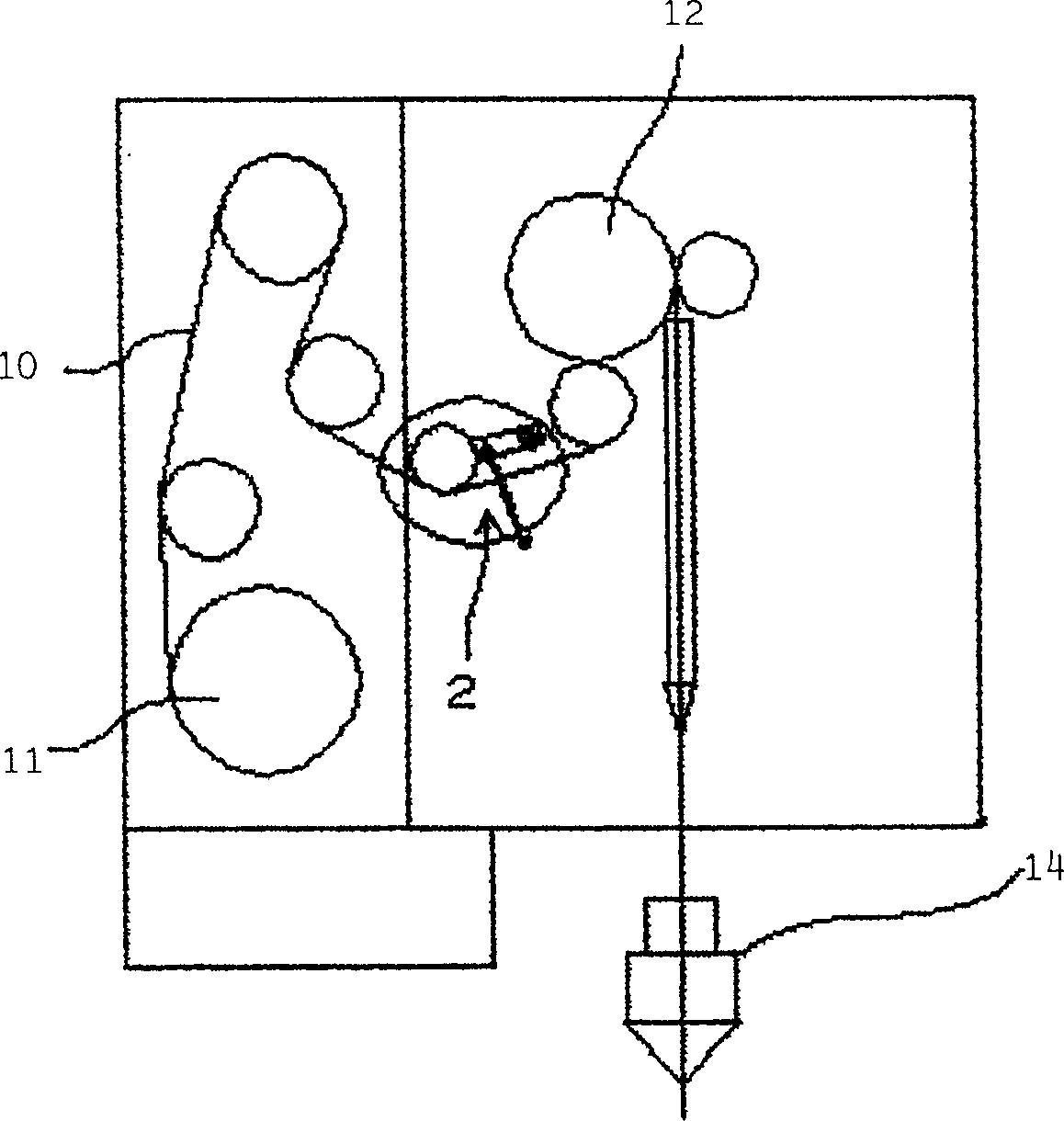

[0036] figure 1 It is a figure for demonstrating the schematic structure of the wire electric discharge machine of this invention. The wire electric discharge machine 1 is the same as the prior art shown in the above-mentioned FIG. 16. A wire-feeding system for supplying and winding-up the wire in the order of taking up the bobbin 17, in which a lowering wire is set between the wire supplying bobbin 11 and the braking roller 12 The device (wire tension fluctuation reduction device) 2 for the fluctuation of the tension of the wire is used to control the tension fluctuation of the wire generated by the brake roller 12 on the wire supply side by the wire tension fluctuation reduction device 2.

[0037] exist figure 1On the side closer to the wire supply side than the brake roller 12, if the tension of the wire changes due to changes in the rotational speed of the wire supply bobbin 11 or frictional changes in the brake roller 12, etc., the The wire tension fluctuation reduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com