Polarization film and its manufacturing method, polarization sheet and optical laminating body

A technology of polarizing film and manufacturing method, which is applied to optics, optical elements, polarizing elements, etc., can solve the problems of color spots on polarizing films and quality degradation of polarizing films, and achieve the purpose of suppressing tension changes, stabilizing operation, and reducing film color spots Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

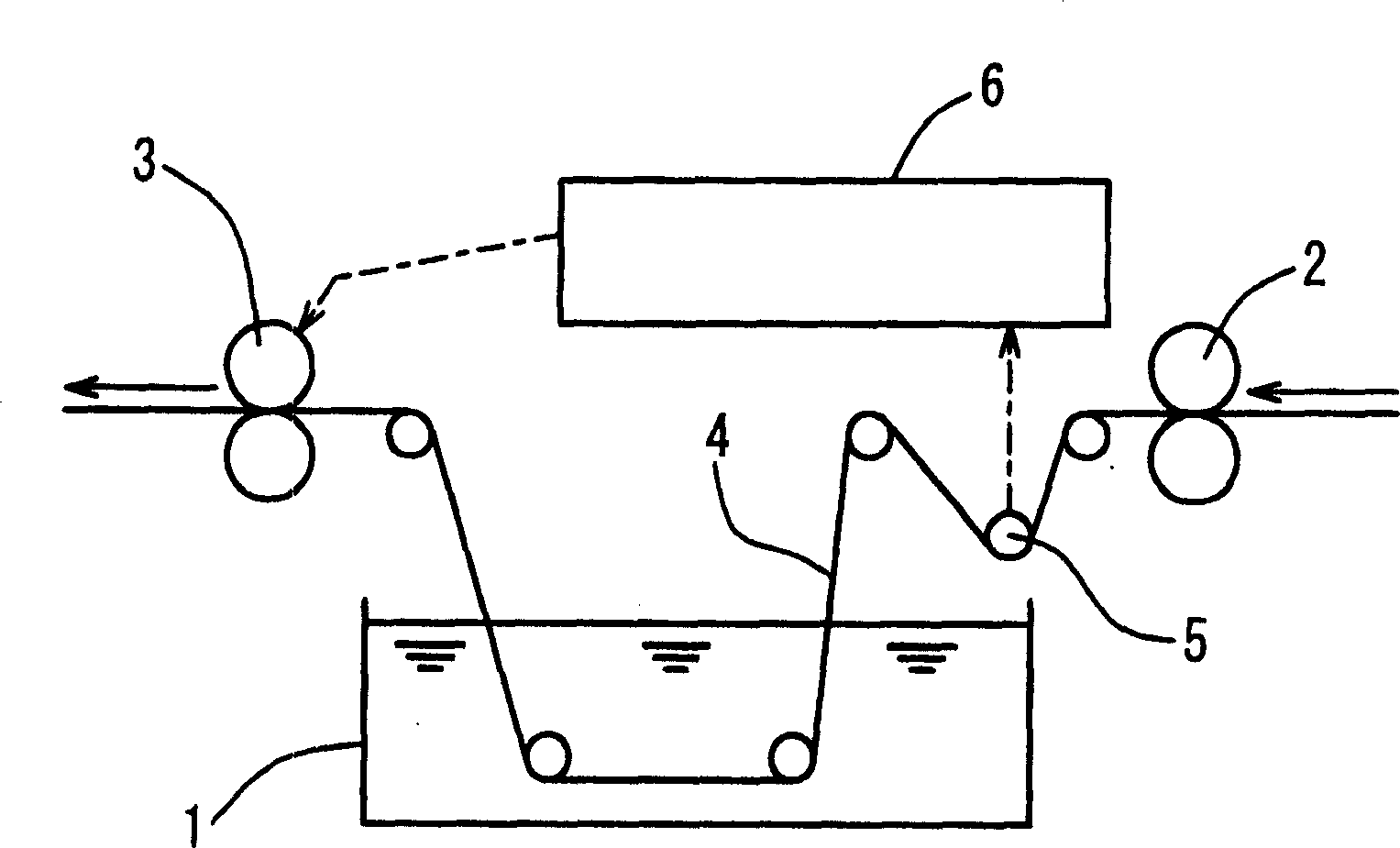

Image

Examples

Embodiment 1

[0070] A polyvinyl alcohol film with a thickness of 75 μm (Kurarevinylon VF-PS#7500, a degree of polymerization of 2400, a degree of saponification of 99.9 mol% or more) was placed in pure water at 30°C, and the film was kept in a tense state so that the film would not sag , Dip for about 130 seconds to fully expand the film.

[0071] Next, the film was uniaxially stretched while being dipped in an aqueous solution having a weight ratio of iodine / potassium iodide / water of 0.02 / 1.5 / 100 for dyeing treatment. Then, while immersing the film in a 60°C aqueous solution with a weight ratio of potassium iodide / boric acid / water of 10 / 5 / 100 for boric acid treatment, it was uniaxially stretched until the accumulated stretch ratio was 5.9 times the original. Further, at 40° C., the film was immersed in an aqueous solution with a weight ratio of potassium iodide / boric acid / water of 10 / 3 / 100 for about 30 seconds to perform the second boric acid treatment. After performing the second boric ...

Embodiment 2

[0076] The procedure was carried out in the same manner as in Example 1, except that the second-step boric acid treatment and tension control were performed as described below.

[0077] While immersing the film in a 60°C aqueous solution with a weight ratio of potassium iodide / boric acid / water of 10 / 5 / 100 for boric acid treatment, it was uniaxially stretched until the cumulative stretching ratio was 5.9 times the original. Further, at 60° C., the film was immersed in an aqueous solution having a weight ratio of potassium iodide / boric acid / water of 10 / 5 / 100 for about 30 seconds to perform a second boric acid treatment.

[0078] In the second boric acid treatment and water washing process, the tension is controlled while detecting each tension.

[0079] The result of obtaining the standard deviation of the orthogonal b' value is as follows: the standard deviation is 0.2, and the obtained polarizer has few color spots.

Embodiment 3

[0081] Except for carrying out the third step of boric acid treatment and tension control as described below, the same operation as in Example 1 must be carried out.

[0082] The film was uniaxially stretched while being immersed in a 55°C aqueous solution with a weight ratio of potassium iodide / boric acid / water of 10 / 5 / 100, and further immersed in a film with a weight ratio of potassium iodide / boric acid / water of 10 / 5. / 100 in a 60°C aqueous solution for the second waterproofing treatment while performing uniaxial stretching until the cumulative stretching ratio is 5.9 times the original. Further, at 40° C., the film was immersed in an aqueous solution having a weight ratio of potassium iodide / boric acid / water of 10 / 3 / 100 for about 30 seconds to perform the third boric acid treatment. In the third boric acid treatment and water washing process, the tension is controlled while detecting each tension.

[0083] The result of obtaining the standard deviation of the orthogonal b'...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com