Intermittent coating apparatus

A coating device and coating technology are applied in the direction of devices and coatings for coating liquid on the surface, which can solve the problems of influence of coating thickness, difficulty in coating liquid coating, and difficulty in improving productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

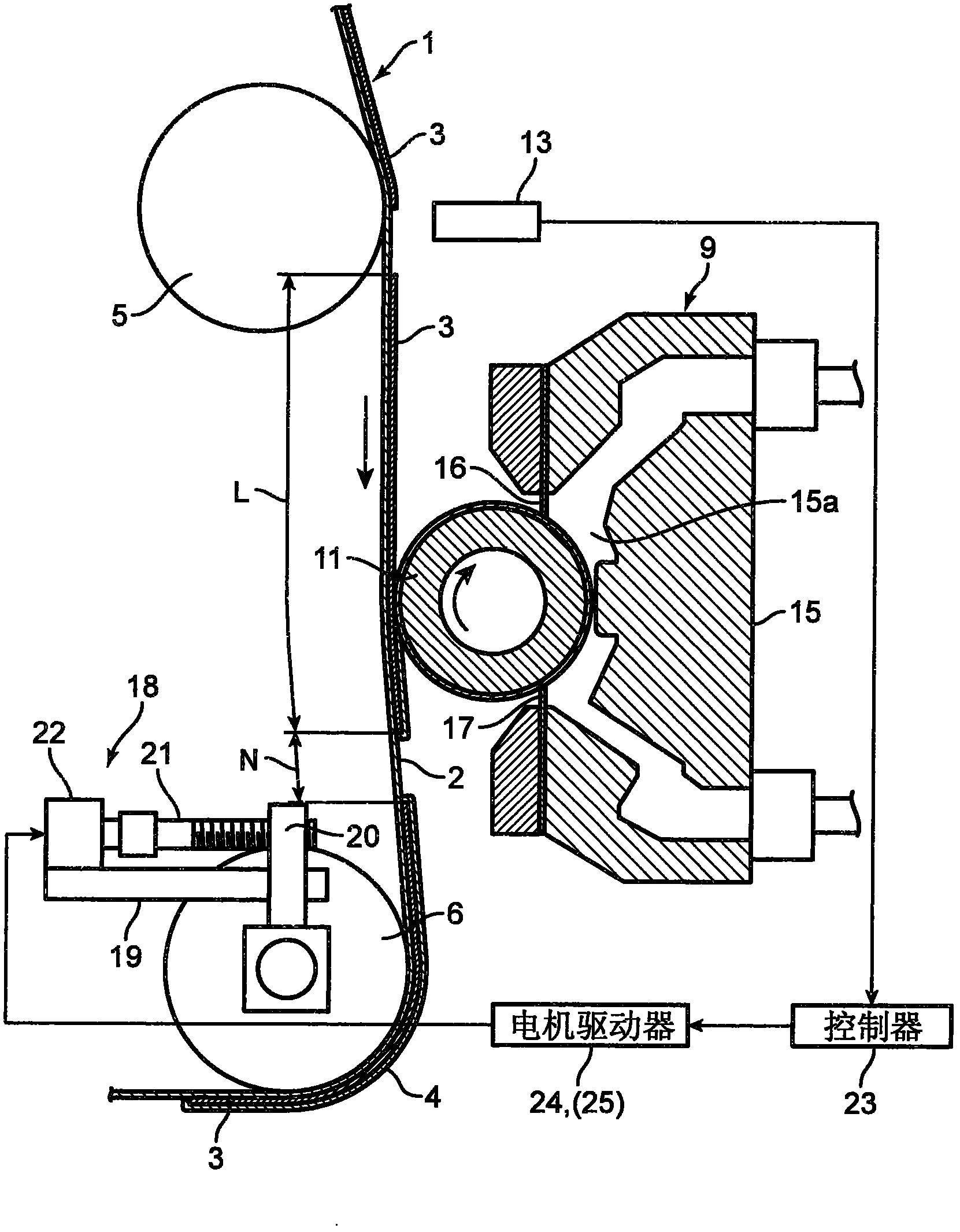

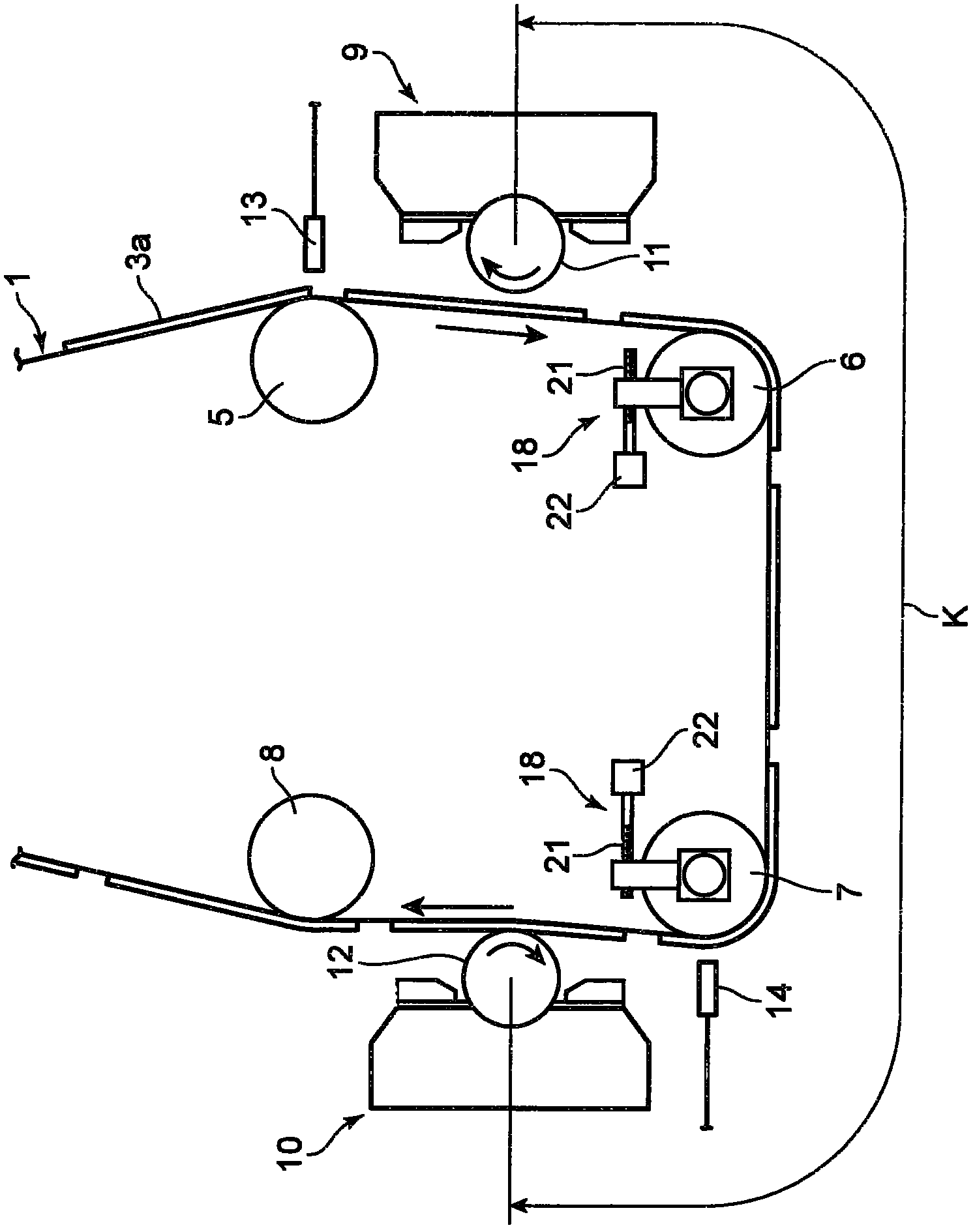

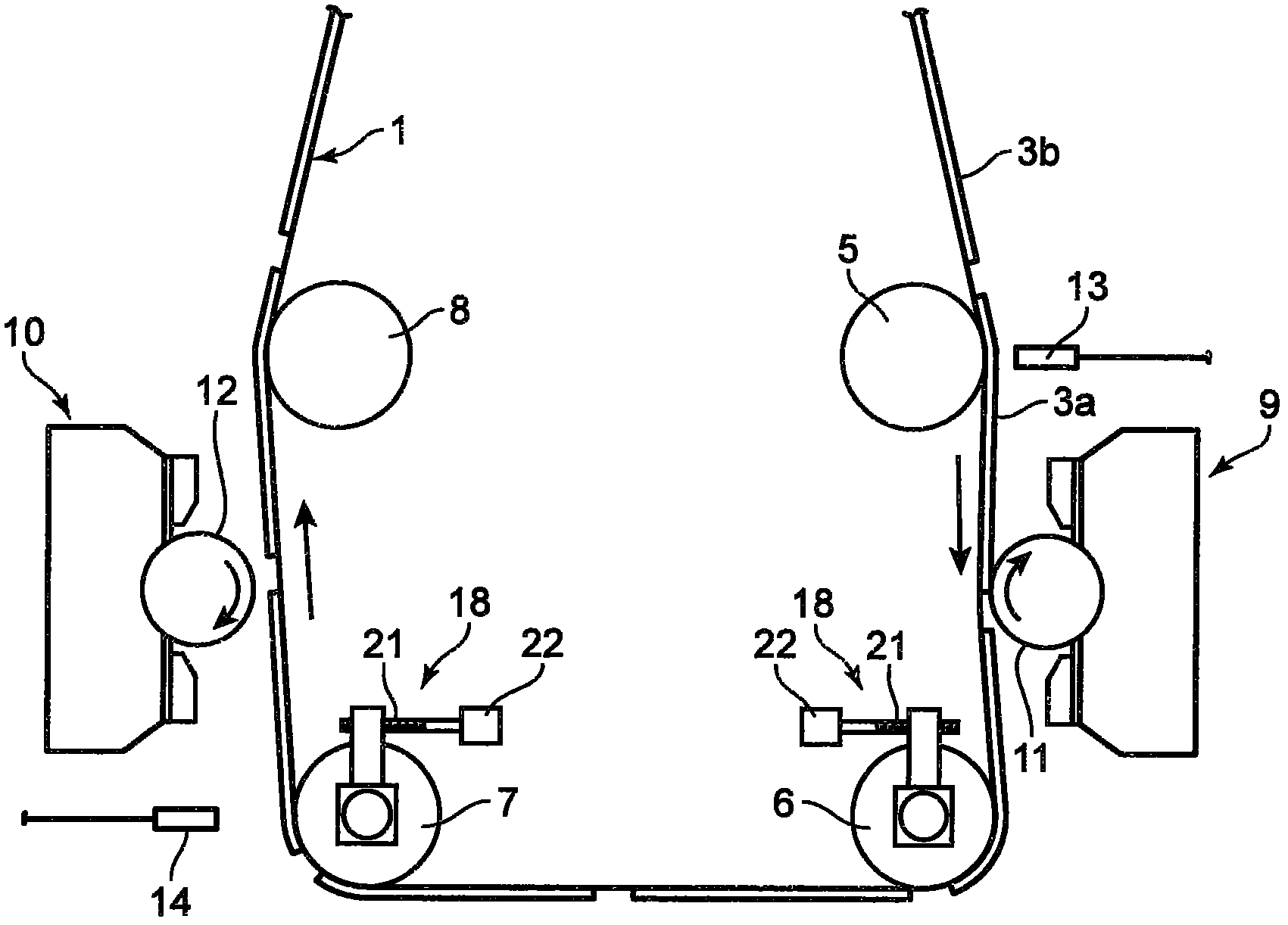

[0043] figure 1 as well as figure 2 The first embodiment of the intermittent coating device according to the present invention is shown in , which is a device for intermittently coating a coating agent on a substrate 1 constituting a negative electrode plate of a battery such as a lithium ion secondary battery. . Specifically, the intermittent coating device continuously arranges battery-use coatings 2 having a thickness of about 80 μm at predetermined intervals on a sheet-shaped current collector 2 composed of a copper sheet having a thickness of approximately 10 μm at a predetermined speed. When the substrate 1 made of the active material layer 3 is conveyed, a coating agent consisting of a ceramic paste is intermittently applied to the surface of the substrate 1 and dried to form a film having a film thickness of 10 μm or less, for example, The thin porous protective film 4 covering the surface of the battery active material layer 3 has a thickness of 2 μm±1 μm.

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com