Floating roll feedback type yarn tension control device of one-time warping machine

A yarn tension and floating roller technology, applied in the field of warping machines, can solve the problems of low tension control accuracy, inconsistent tension, overloading of transmission parts, etc. Smooth and shock-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

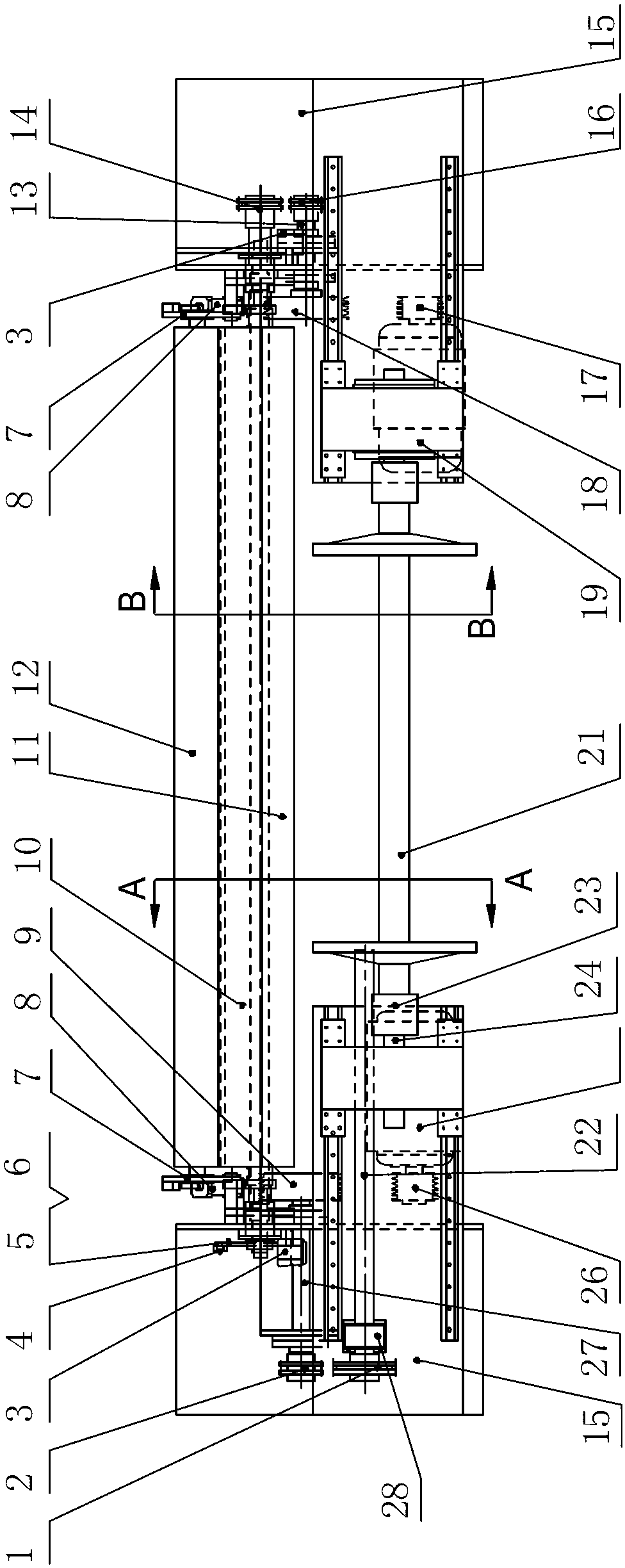

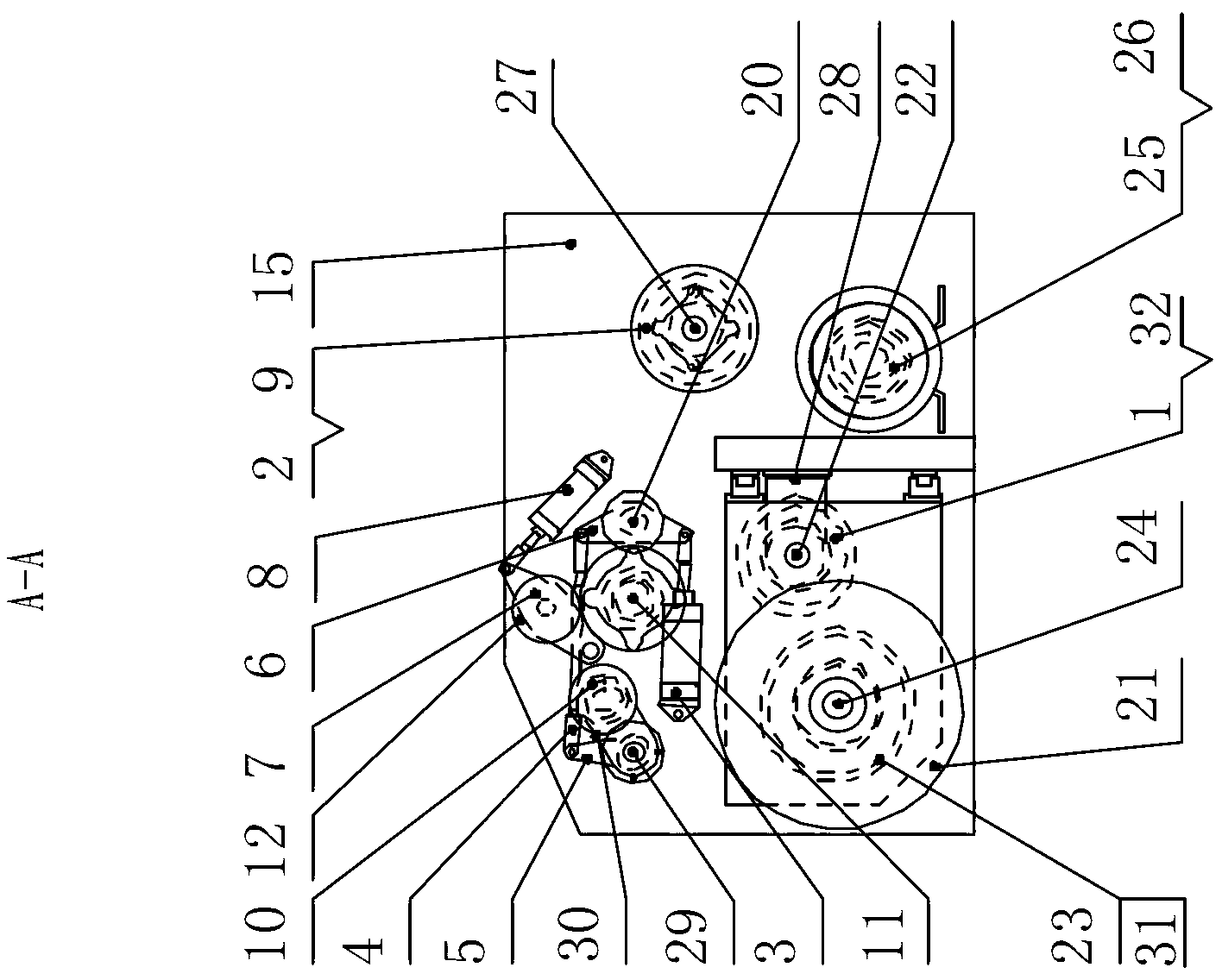

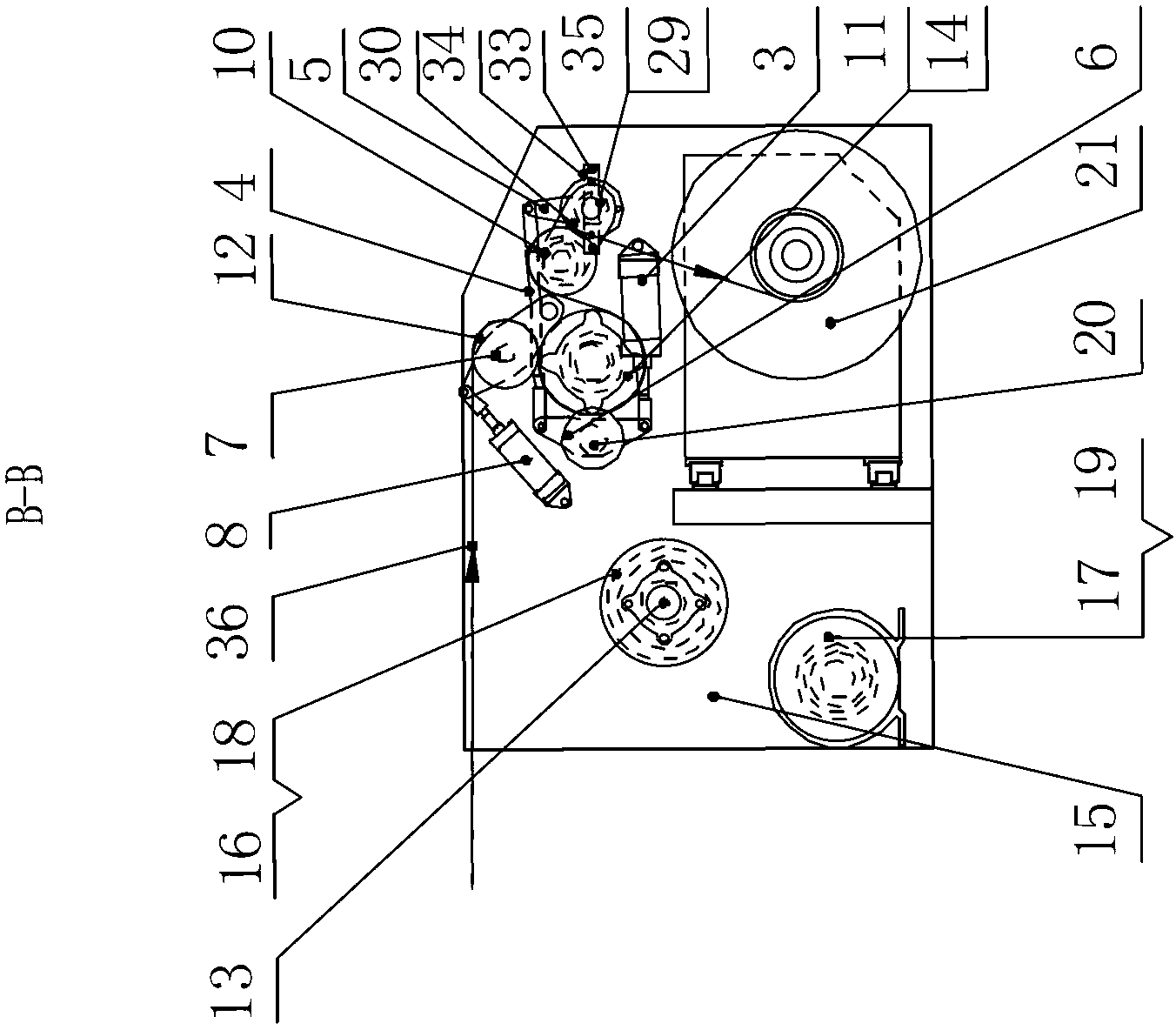

[0016] Describe the present invention in detail below in conjunction with accompanying drawing:

[0017] Floating roller feedback yarn tension control device of disposable warping machine, such as Figure 1-4 As shown, the device includes: a frame 15, a circuit and air circuit control system, a weaving shaft transmission mechanism, a yarn traction mechanism, and a tension feedback mechanism;

[0018] The circuit and air circuit control system of this machine are currently commonly used automatic control systems; during the warping process, the PLC controls the two frequency conversion motors through the frequency converter - the weaving shaft frequency conversion motor 25 and the traction roller frequency conversion motor 19 control the warped yarn Thread tension and warping speed, the size of the yarn tension is adjusted by the air pressure of the floating roller cylinder 3;

[0019] Weaving shaft transmission mechanism: this mechanism includes the weaving shaft frequency co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com