Non-contact yarn tension testing device by utilization of CCD technology

A yarn tension and testing device technology, applied in the direction of tension measurement, making pile cloth products, etc., can solve the problems of wear detection device, influence of yarn running state, unable to truly reflect yarn tension, etc., to achieve accurate detection, The effect of increasing the resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

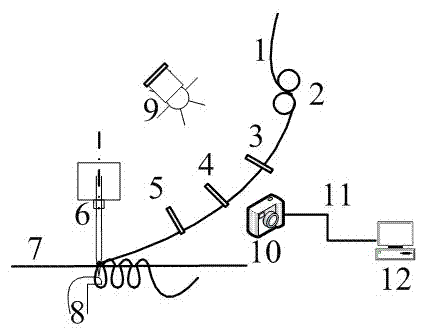

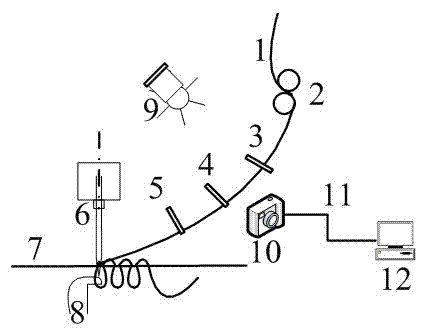

[0012] Such as figure 1 As shown, it is a schematic structural diagram of a non-contact yarn tension testing device. The non-contact yarn tension testing device includes a constant tension yarn guide roller 2, which is respectively arranged on the constant tension yarn guide roller 2 and the tufted carpet loom. On both sides of the yarn transmission path between the tufting needles 6, an angle-adjustable auxiliary light source 9 and a CCD image sensor 10, the CCD image sensor 10 is connected to a computer 12 through a USB interface data transmission device 11. A fixed yarn guide 3, a first adjustable yarn guide 4 and a second adjustable yarn guide are arranged on the yarn transmission path between the constant tension yarn guide roller 2 and the tufting needle 6 of the tufted carpet loom. Yarn device5.

[0013] During use, the yarn line segment image to be measured is continuously captured by the CCD image sensor 10, and after being enlarged and processed, it is input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com