Outer yarn tension regulating method for direct twisting machine

A technology of tension adjustment and straight twisting machine, which is applied in textiles and papermaking, and can solve the problems of high energy consumption and noise of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

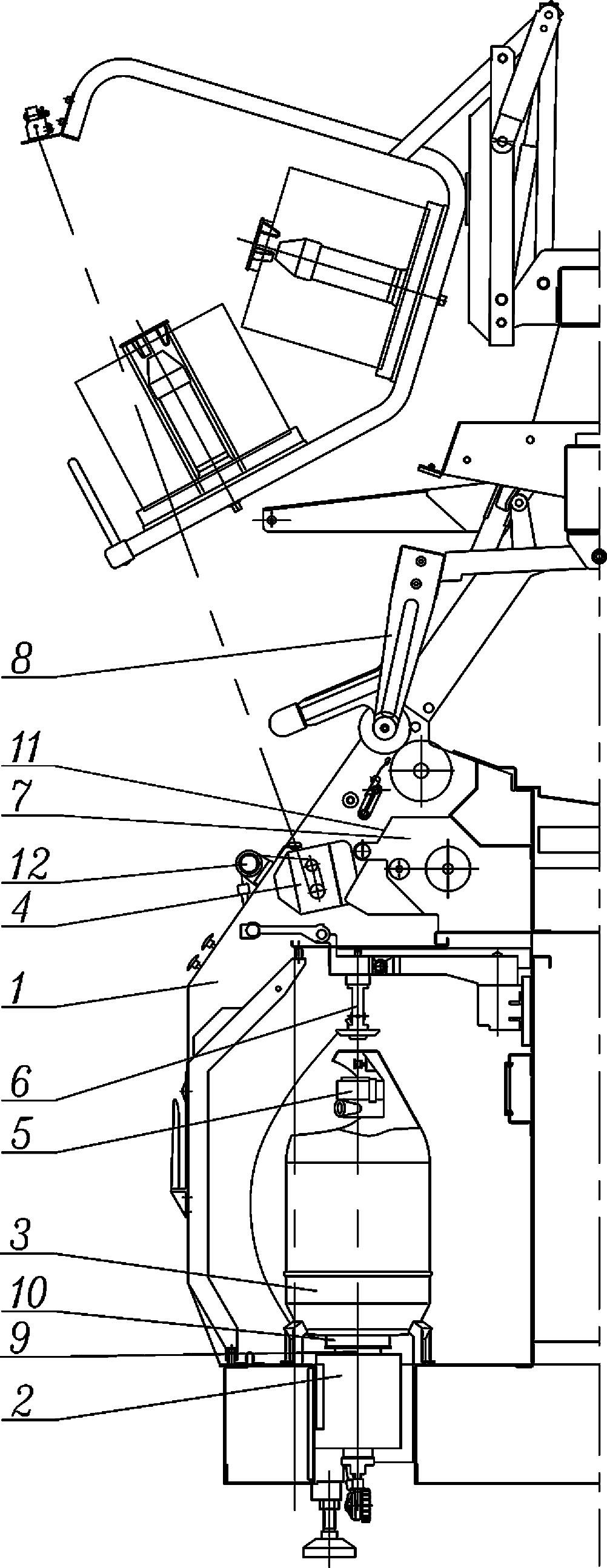

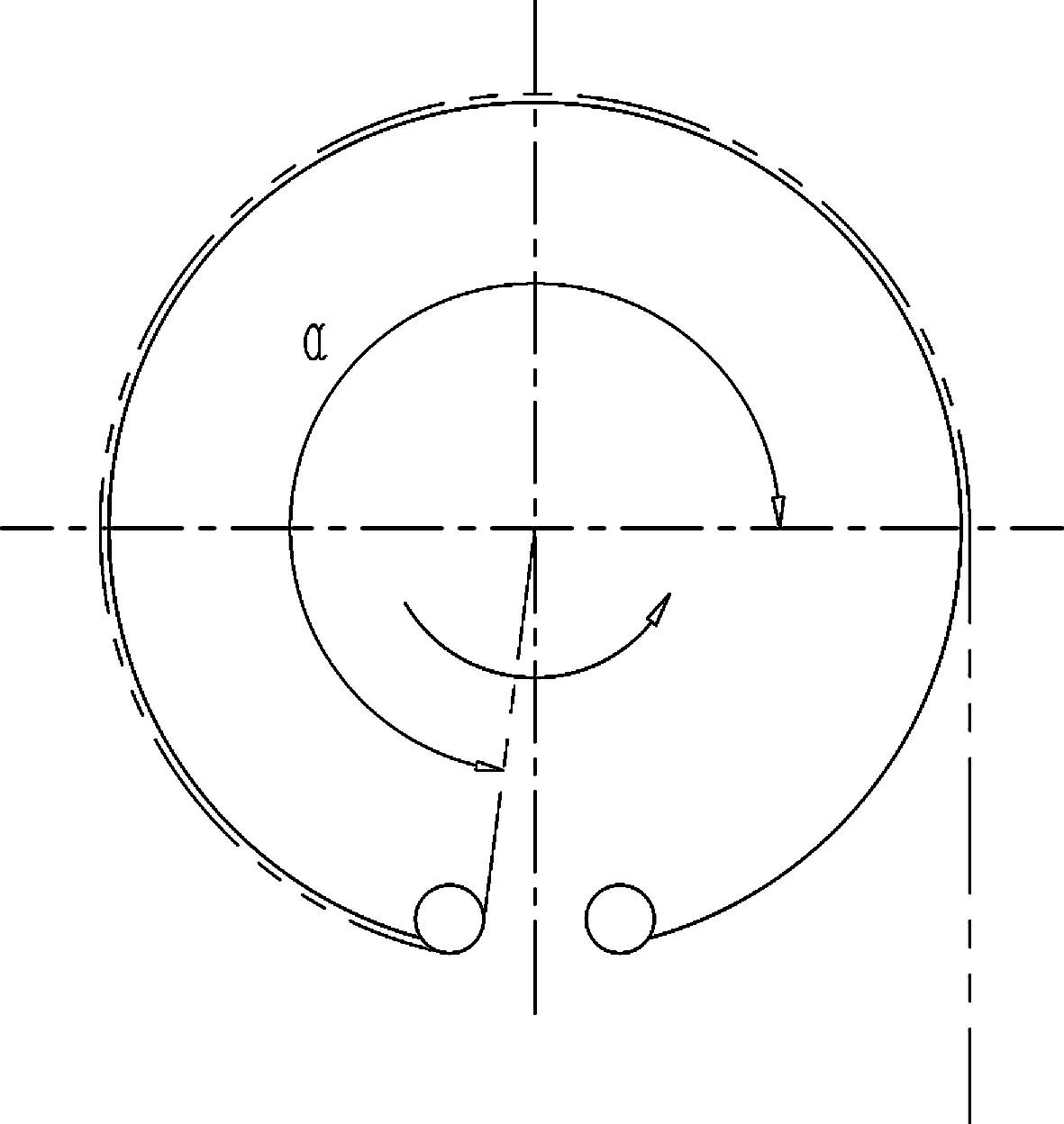

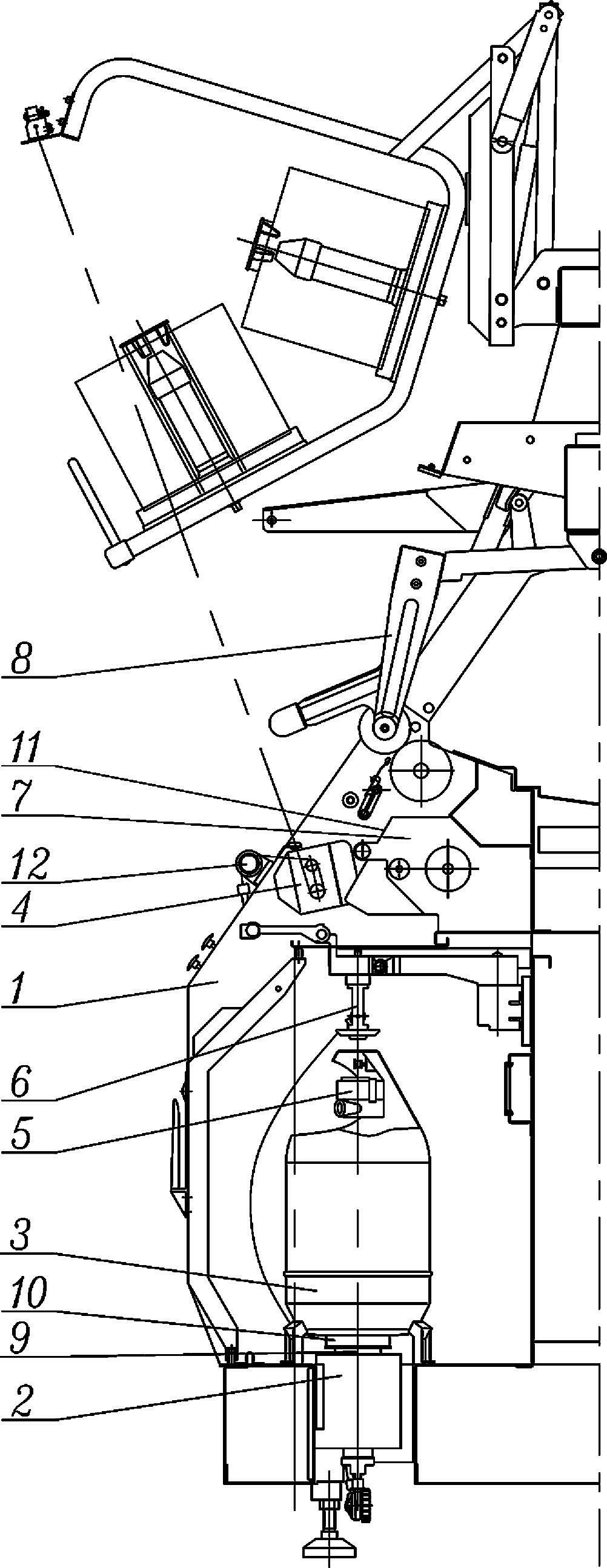

[0015] Specific embodiment one, such as figure 1 As shown, the outer yarn sequentially passes through the outer yarn tensioner 4, the spindle 3, and the yarn storage disc 10 located on the spindle 3, and merges with the inner yarn at the twist leveler 6. The steps for adjusting the tension of the outer yarn are as follows: A. Driven by the motor 2 The spindle 3 makes the outer yarn rotate to form a balloon; B. After the balloon is formed, use the control device 11 to adjust the tension through the outer yarn tensioner 4, so that the outer yarn surrounds the wrapping angle α of the yarn storage disc 10 Gradually reduce to 0 degrees, so as to achieve the effect of reducing the air circle.

specific Embodiment 2

[0016] Specific embodiment two, such as figure 1 As shown, on the basis of the first embodiment, an outer yarn tension detection sensor 12 is arranged between the outer yarn tensioner and the spindle, and the outer yarn tension detection sensor is used to detect the magnitude of the outer yarn tension. The control device 11 controls the outer yarn tensioner 4 according to the outer yarn tension value detected by the outer yarn tension detection sensor 12 to adjust the tension of the outer yarn so that the outer yarn wraps around the yarn storage disc. The angle α gradually decreases to 0 degrees, thereby achieving the effect of reducing the balloon.

[0017] In the above technical solution, under the same working conditions, the tension of the outer yarn is only changed by the outer yarn tensioner 4, and the shape of the balloon is adjusted to reduce the resistance of the air to the balloon, thereby reducing the energy consumption and the energy consumption of the equipment du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com