Beam dyeing sizing machine suitable for dyed sizing production

A sizing machine and sizing technology, which is applied in the processing of textile materials, textile processing machine accessories, textiles and papermaking, etc., can solve the problems of non-continuous production, ordinary pulp, and high-quality and efficient production of yarn-dyed fabrics. Low efficiency of yarn machine and other problems, to achieve the effect of promoting the preparation process, simple production organization, and flexible variety changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described below in conjunction with accompanying drawing:

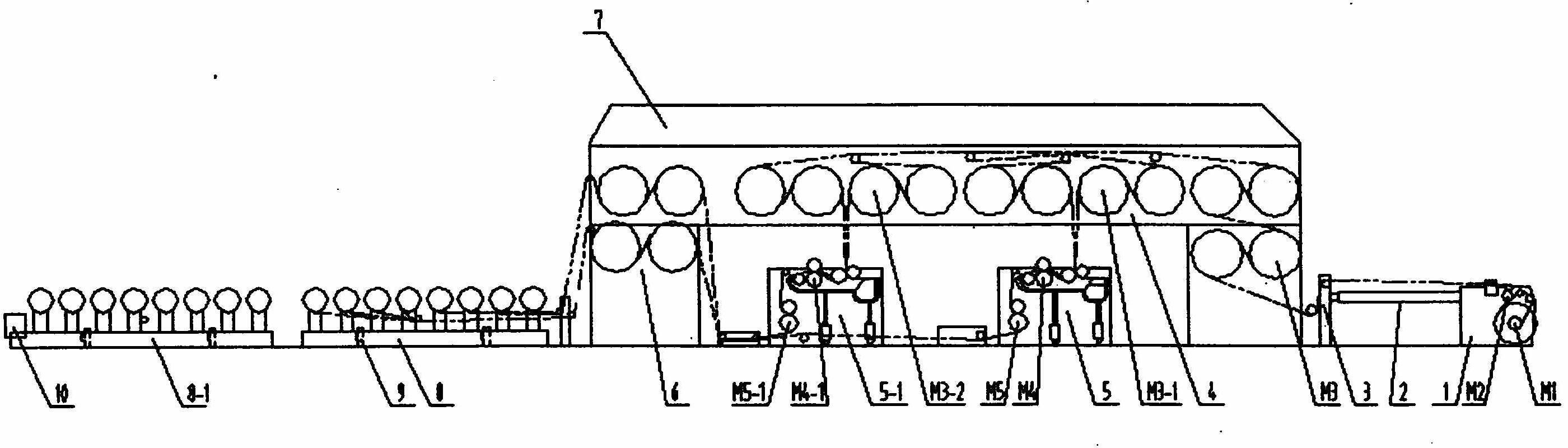

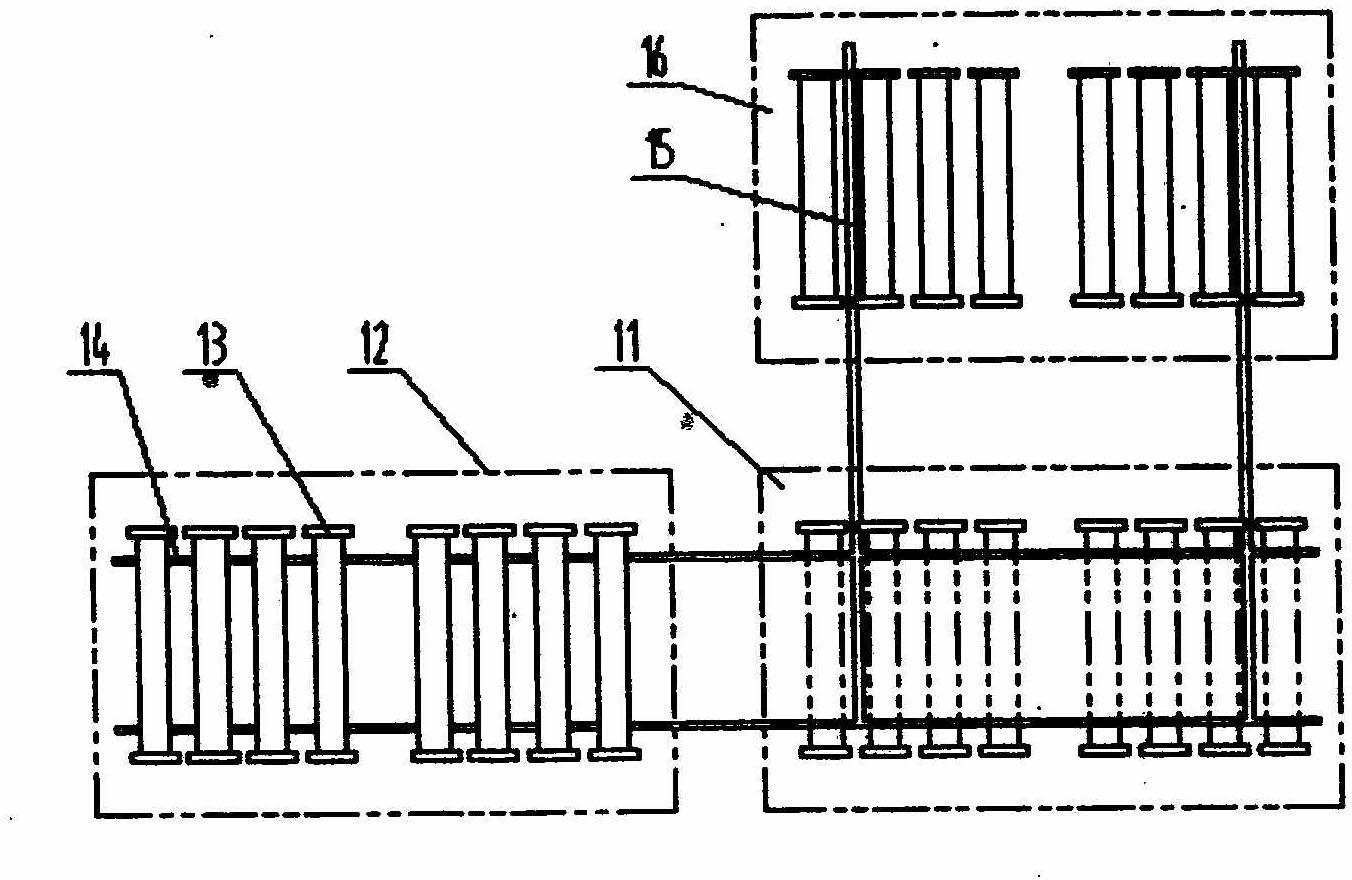

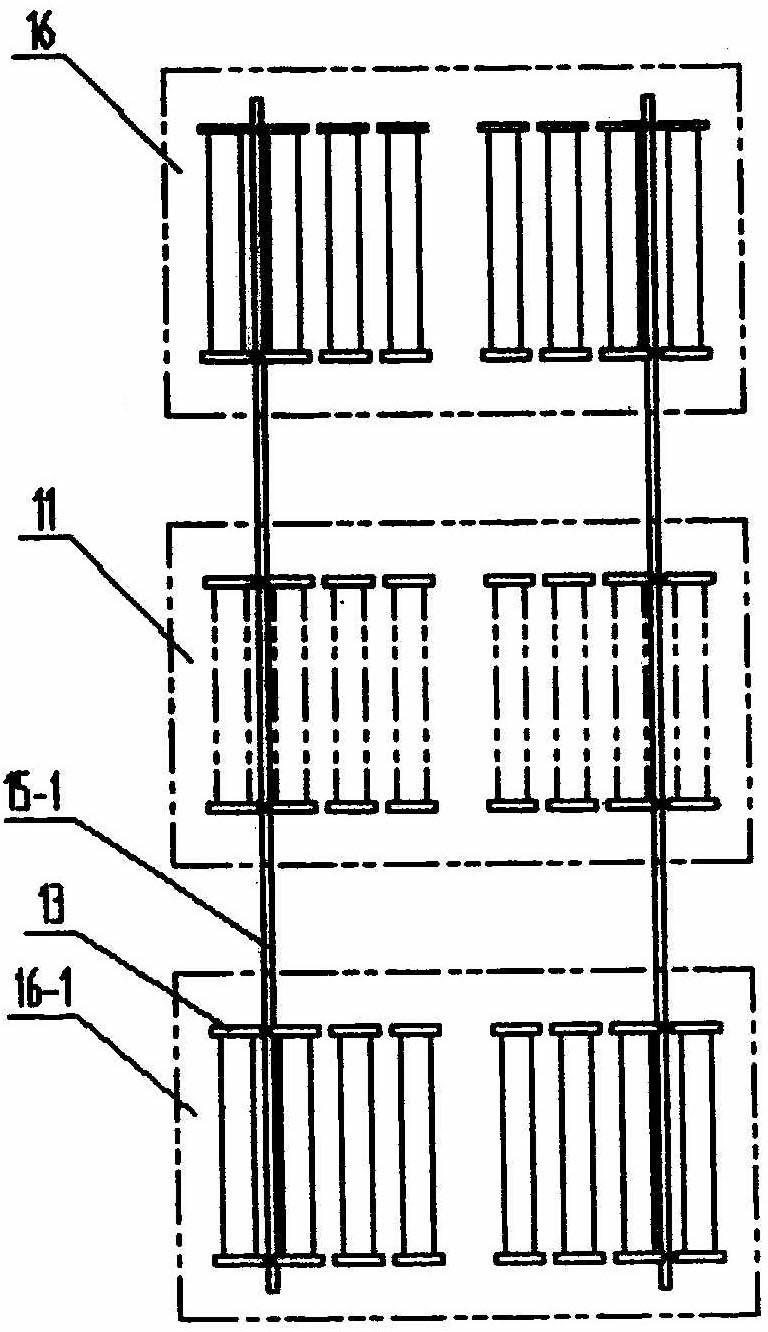

[0037] Such as figure 1 As shown, the double dotted line represents the direction of the yarn, and the present invention includes a winding headstock (1), a dry splitting device (2), a tension waxing device (3), a main drying room (4), and a parallel arrangement of size tanks ( 5.5-1), independent dyed yarn pre-drying room (6), moving warp creel (8, 8-1) and the whole machine transmission and control system, in which the main drying room (4) and colored yarn pre-drying room (6) share a steam cover (7). The movable warp beam frame is designed as the same two groups, and the movable beam frame is provided with a drag motor (10) and a moving wheel set (9), which can reach the working position (11) in an alternately moving manner. Sizing of warp yarns after dyeing. The working principle of this equipment: the colored yarn is divided into two pieces after unwinding and enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com