Yarn dividing tension control device of coating yarn bobbin winder

A technology of tension control and tension adjustment device, which is applied in the direction of thin material processing, transportation and packaging, and delivery of filamentous materials, etc. problems, to achieve the effect of improving driving speed and efficiency, reducing downtime parking, and high-quality process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

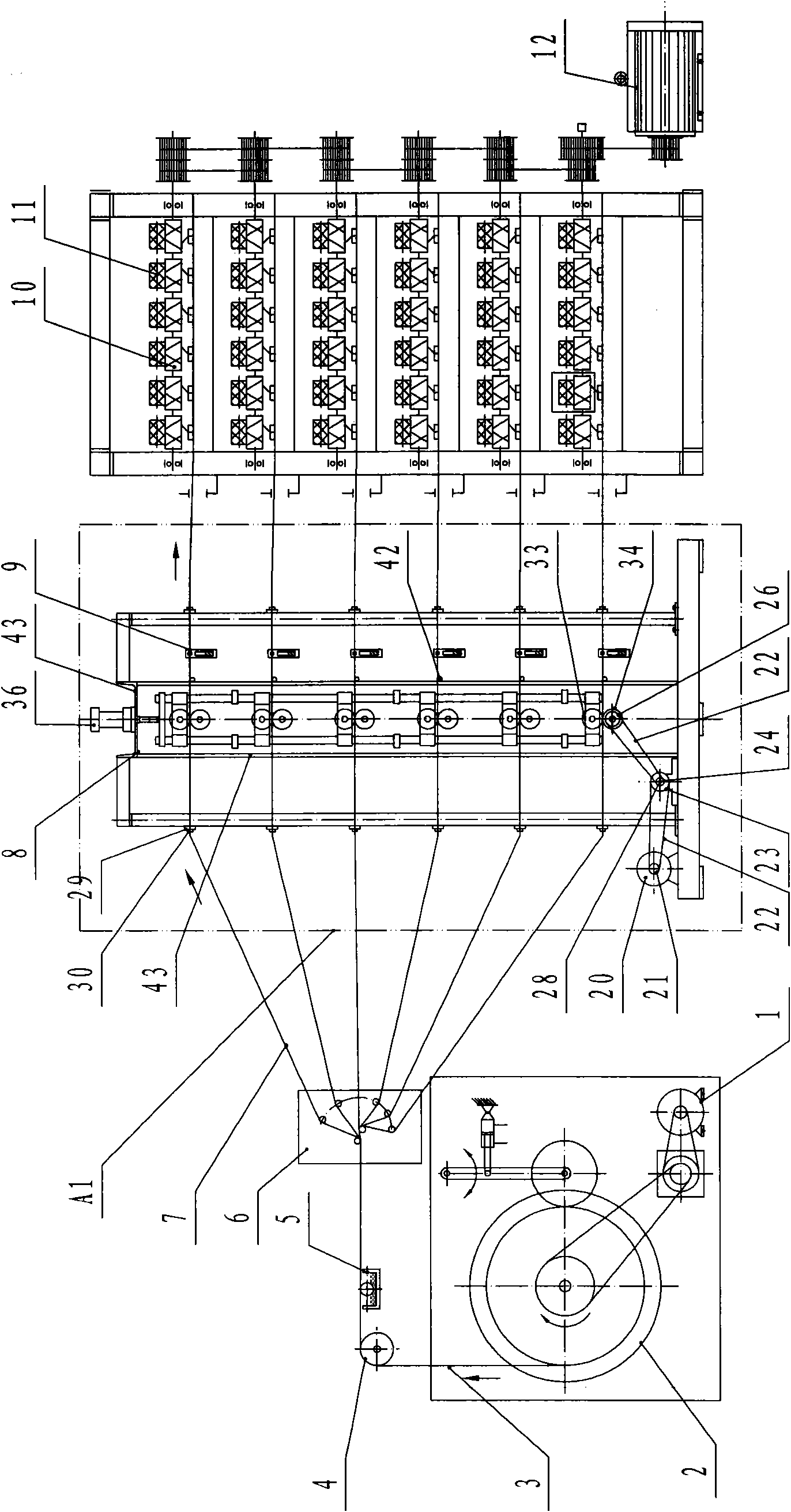

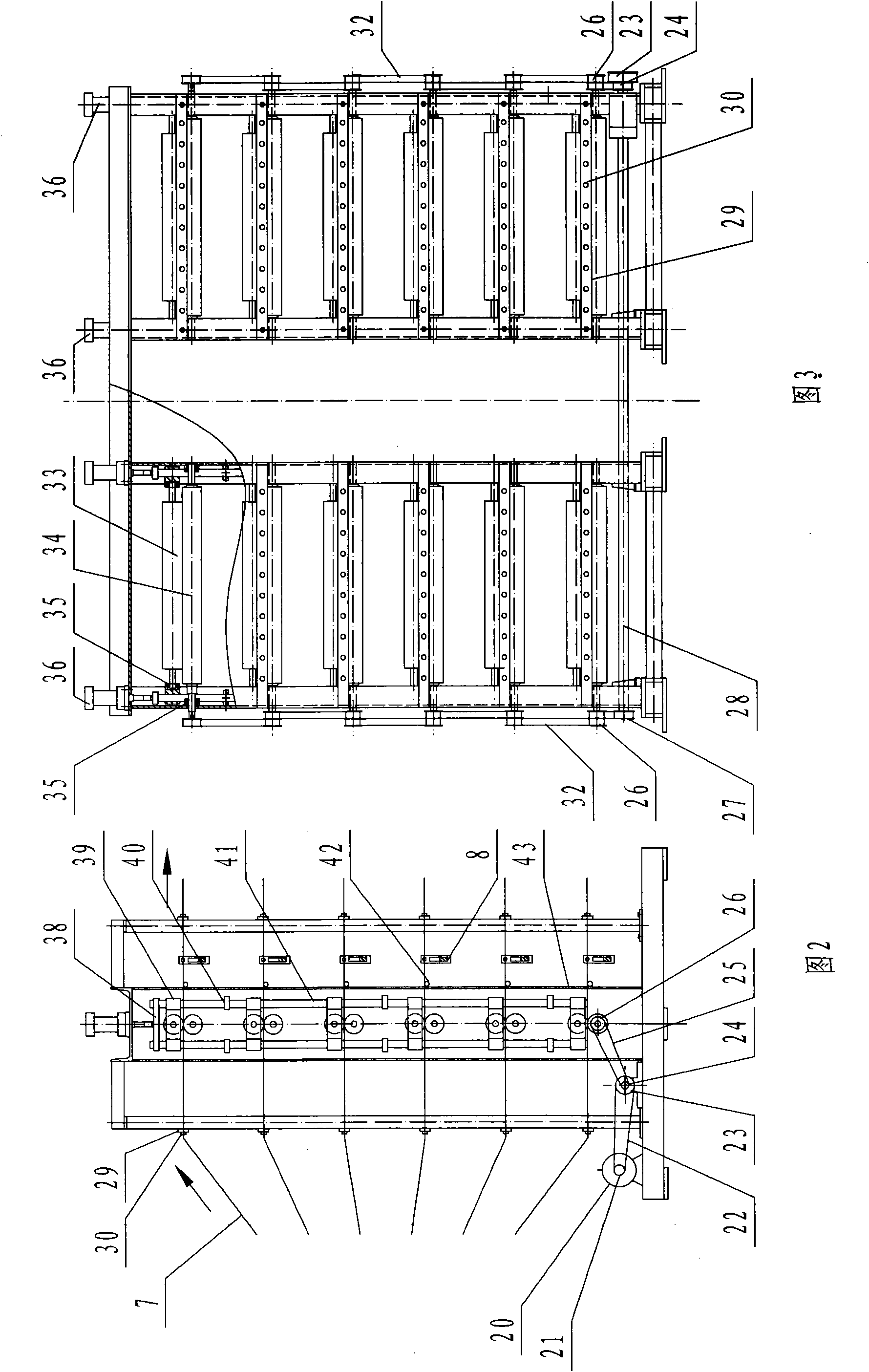

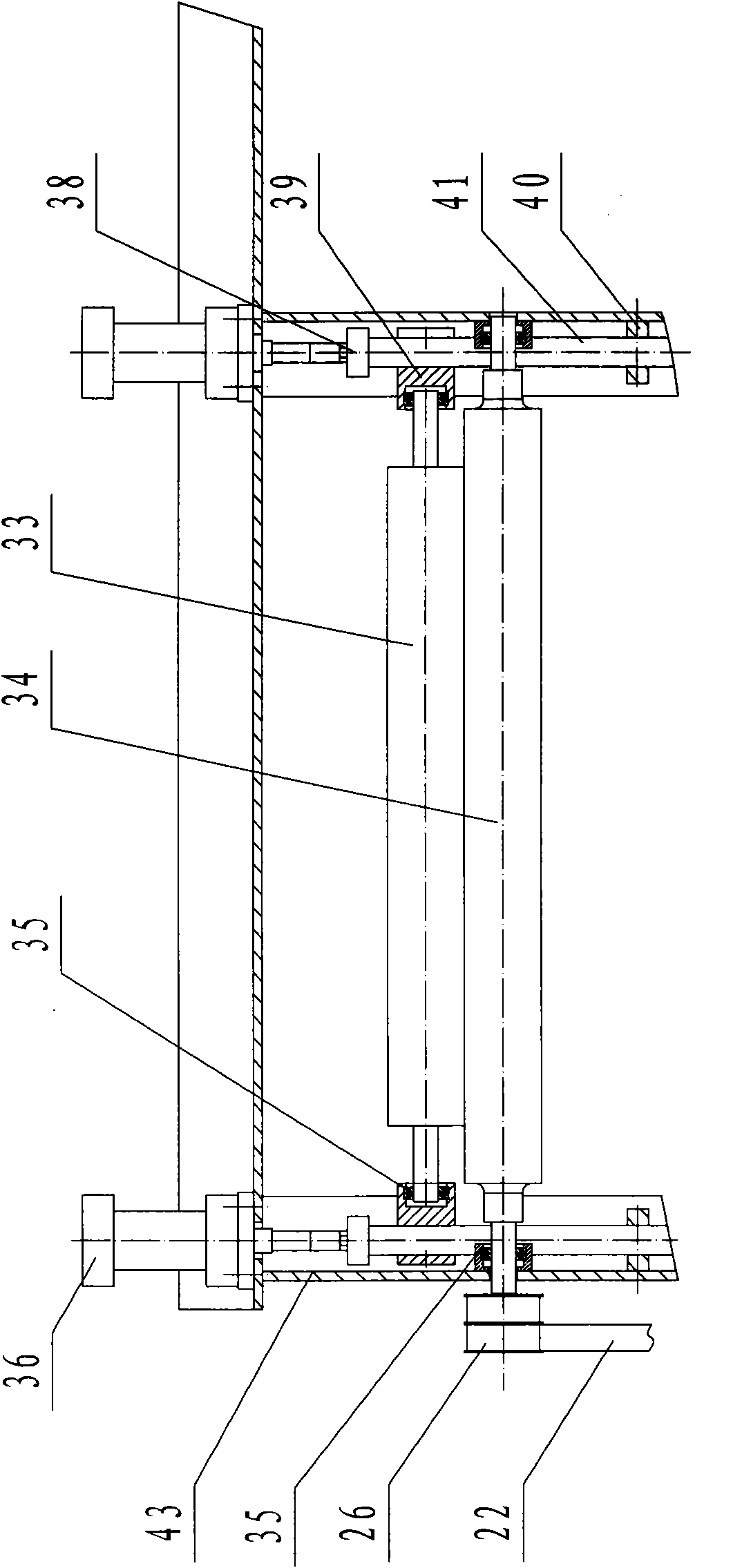

[0018] Describe the present invention in detail below in conjunction with accompanying drawing:

[0019] Such as Figure 1-4 As shown, this device is a tension control device 8 added on the basis of the "paint sheet yarn winder" disclosed in Patent No. 200820185586.3. This device includes the pneumatic control system and electrical control system of the original paint sheet yarn winder. Winding motor 1, warp beam 2, coated sheet yarn 3, machine head transmission device, reversing roller 4, waxing and oiling device 5, splitting device 6, tension adjustment device 9, winding parts 10, package yarn 11, roll Winding motor 12, winding gear. The tension control device 8 is arranged in front of the splitting device 6 and the tension adjusting device 9 of the "coated sheet yarn winding machine" disclosed in the patent No. 200820185586.3 to control the tension of the coating sheet yarn 3 sub-yarns; the tension control device 8 and the tension adjusting device 9 It adopts an integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com