Device and method for feeding an elastomeric yarn to a textile machine

A textile machine, elastic technology, used in textiles and papermaking, knitting, weft knitting, etc., can solve problems such as poor quality of textiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

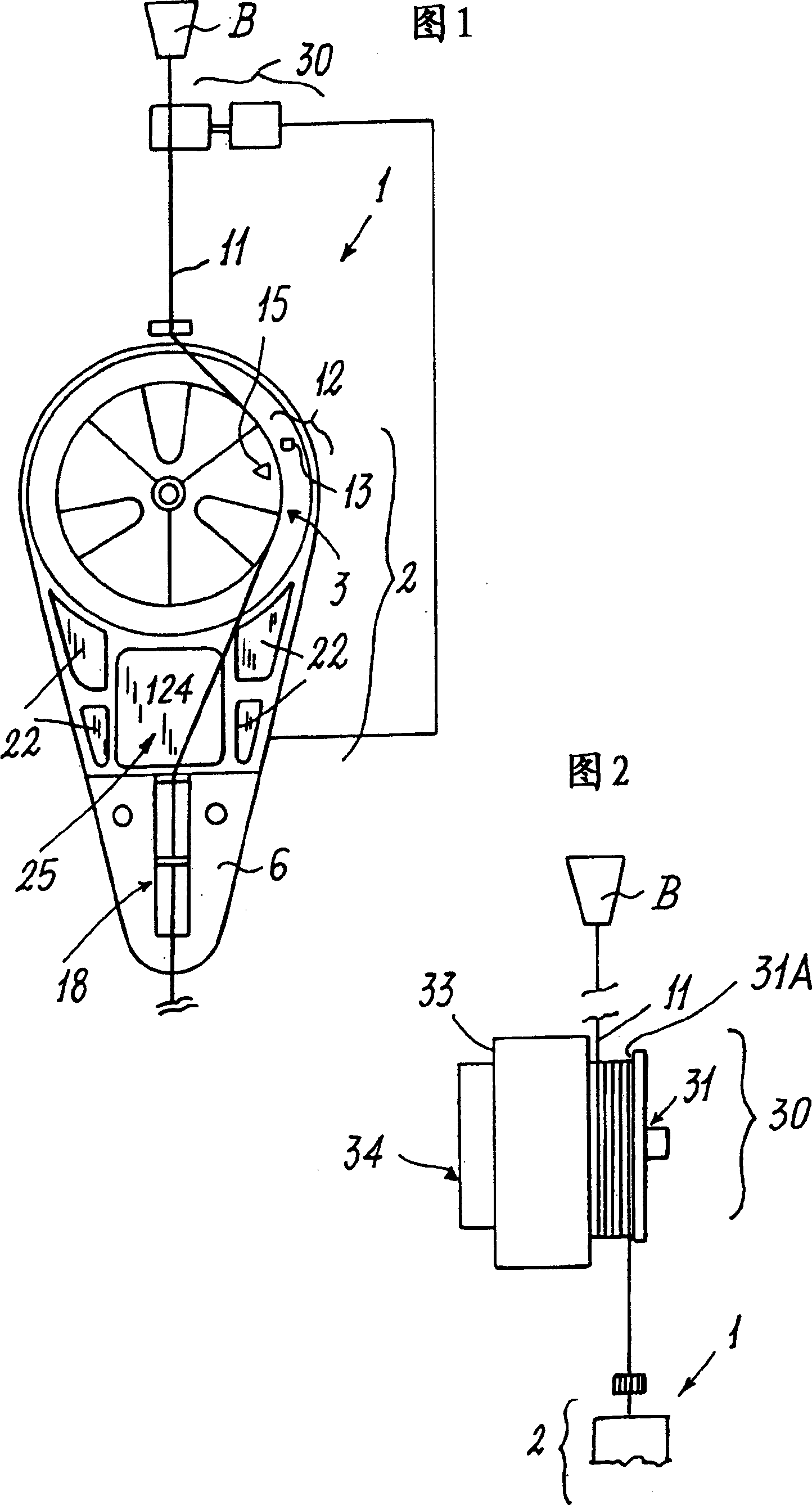

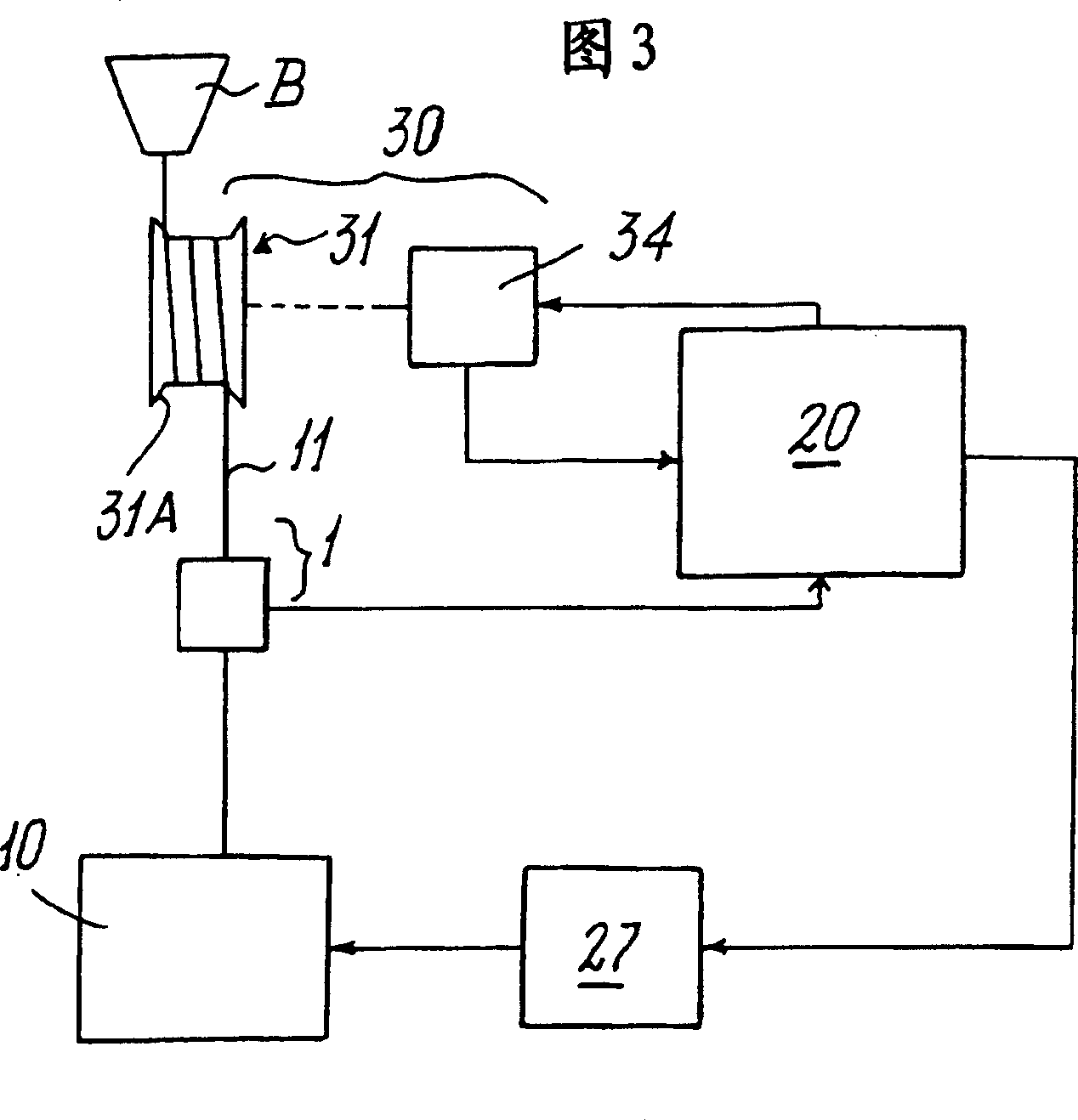

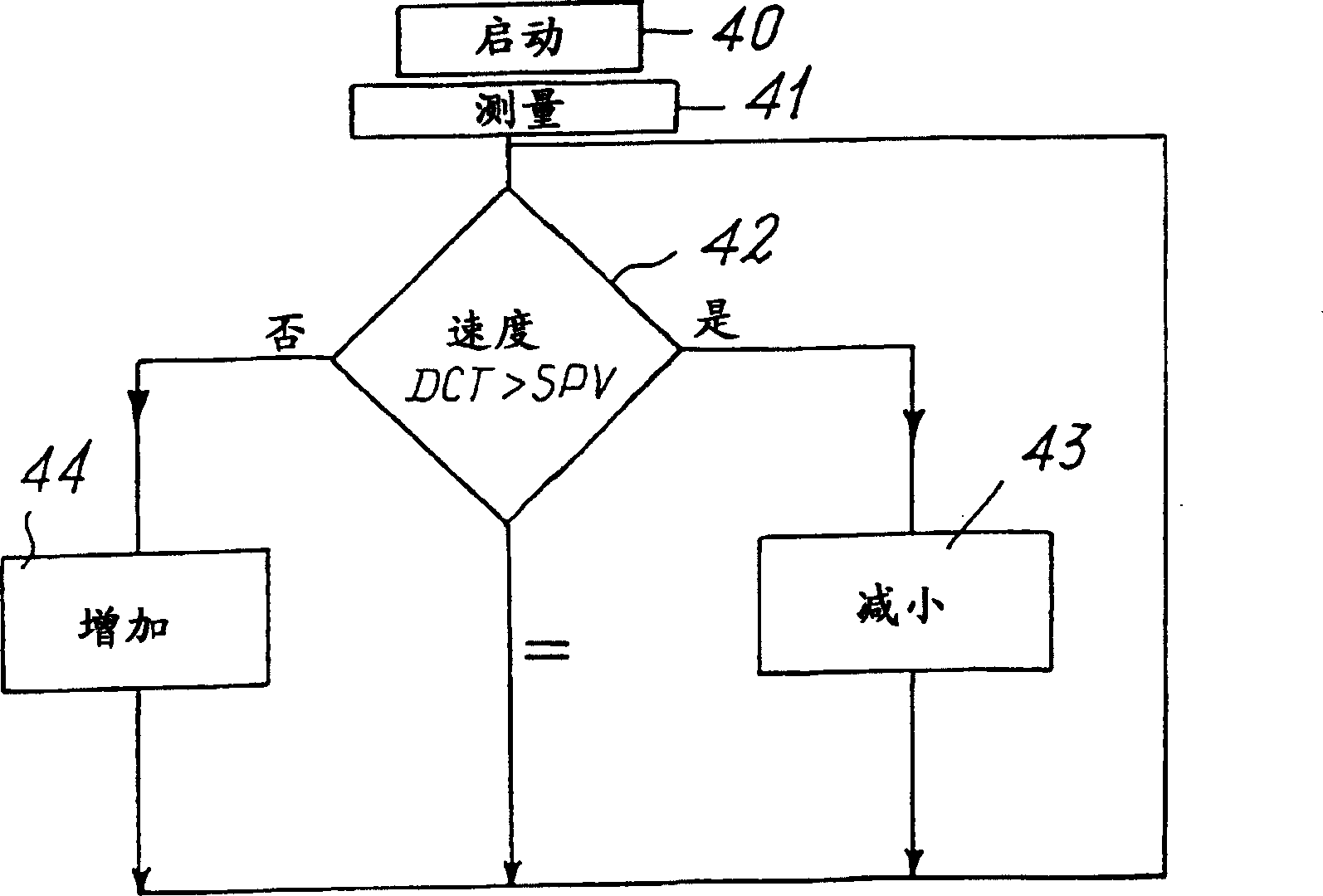

[0020] Referring to the drawings, and in particular to Figures 1 and 2, there is shown an apparatus 1 for feeding a stretch yarn 11 into a textile machine 10 at "constant tension". This device, in Figure 4 Indicated by DTC, including the main body 2 (eg box-like). Attached to the body is a grooved wheel or pulley 3 which is connected to a drive (not shown) for movement. The drive may be an electric motor (for example of the brushless type) connected to the surface of the body 2 opposite the surface 6 on which the pulley 3 is located. Such a device 1 is associated with each elastic yarn 11 to be fed into the textile machine, said yarn being unwound from a bobbin B and wound around a pulley 3 in one or more turns.

[0021] The pulley is directly or indirectly connected to an element 12 which measures the rotation of the pulley and thus the speed of this rotation. This element can be a magnetic sensor 13 connected to the body 2 and cooperating with a magnet 15 connected to a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com