Fiber drawing method

A fiber and pre-drafting technology, applied in the field of drafting process, can solve the problems of inconvenient fineness and tension, fixation, unadjustable silk tension, etc., and achieve the effect of convenient operation, reducing fineness deviation and reducing waste silk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

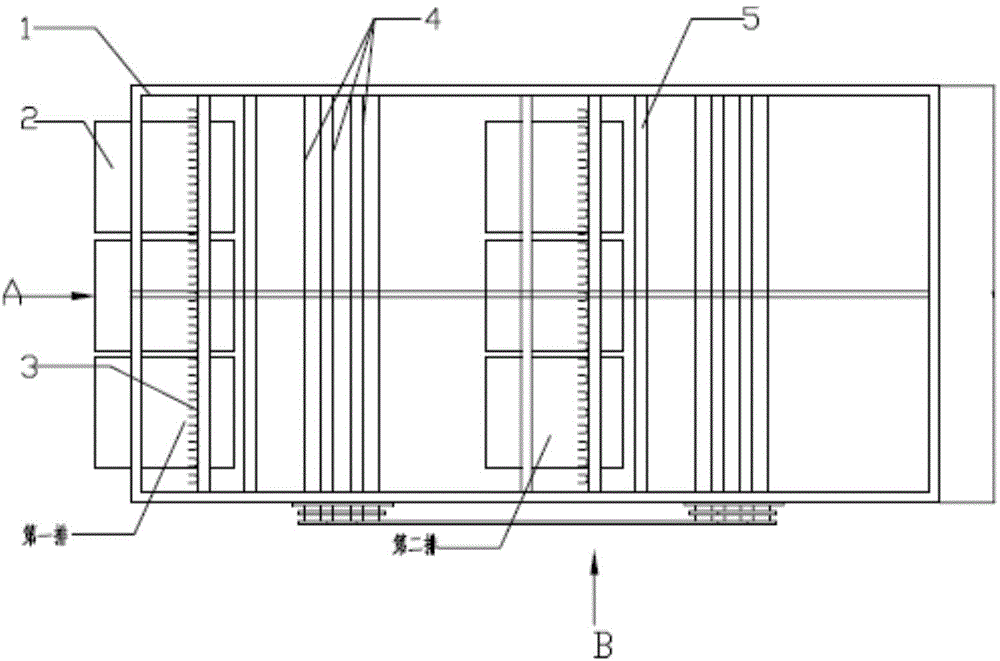

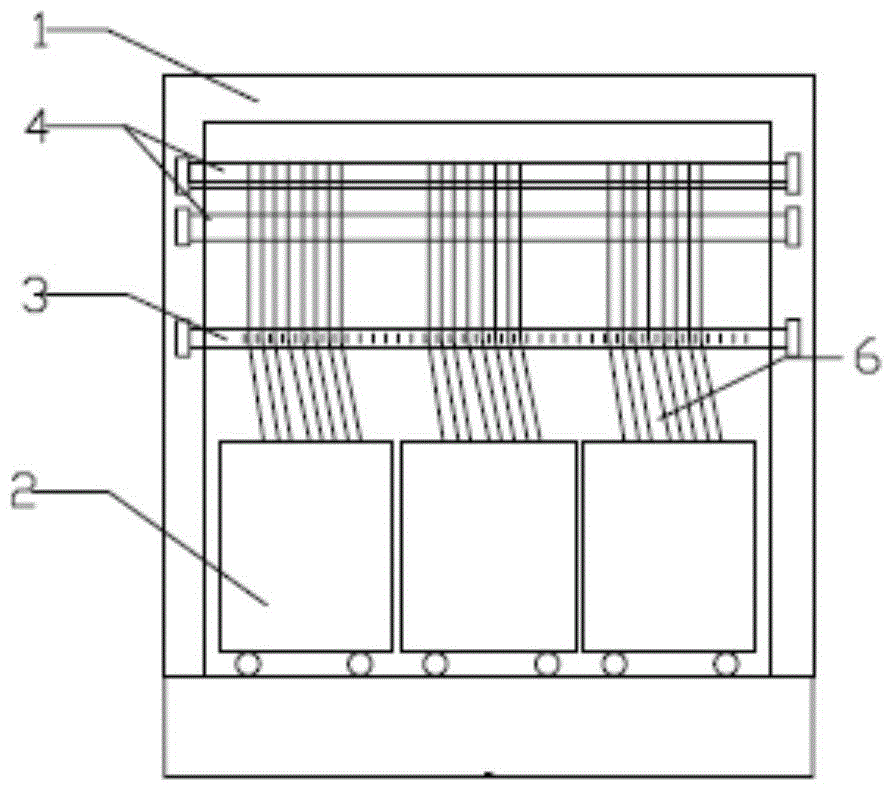

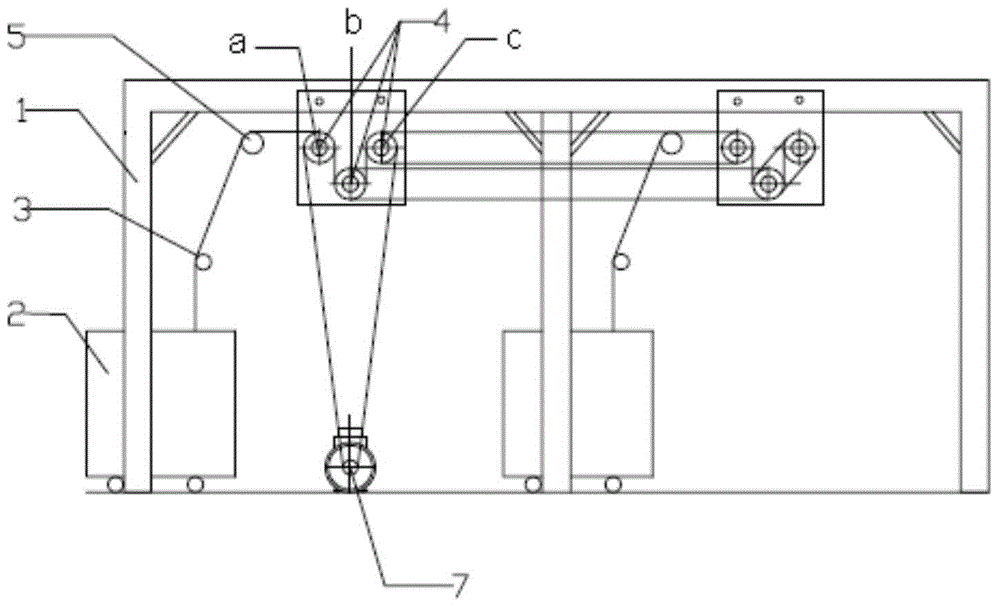

[0029] 1. Prepare 200D jelly silk, put it into the silk barrel 2 and let it stand for several days, waiting for the phase separation to end.

[0030] 2. Bundling: After the phase separation, the jelly filaments 6 are neatly discharged to the cluster frame 1, and divided into three rows, with three barrels in each row. The jelly filaments in the barrels are evenly spread out, and the filaments are actively and orderly discharged, and they are reciprocated in turn. After the rod 3, the circular ring buckle below the godet 5, and the three rolls a, b, and c in the active bundle traction roll group 4, it is drawn to the pre-drawing place. Wherein, the reciprocating rod 3 reciprocates at a uniform speed with a stroke of 10 cm to prevent the filaments from sticking. The diameters of the three rollers in the active cluster traction roller group 4 are 15cm, the distance between roller a and roller c is 30cm, and the roller b moves down 25cm from the same plane of roller a and roller c...

Embodiment 2

[0035] 1. Prepare 600D jelly silk, put it into the silk barrel 2 and let it stand for several days, waiting for the phase separation to end.

[0036] 2. Bundling: After the phase separation, the jelly filaments 6 are neatly discharged to the cluster frame 1, and divided into three rows, with three barrels in each row. The jelly filaments in the barrels are evenly spread out, and the filaments are actively and orderly discharged, and they are reciprocated in turn. After the rod 3, the circular ring buckle below the godet 5, and the three rolls a, b, and c in the active bundle traction roll group 4, it is drawn to the pre-drawing place. Wherein, the reciprocating rod 3 reciprocates at a uniform speed with a stroke of 15 cm to prevent the filaments from sticking. The diameters of the three rollers in the active cluster traction roller group 4 are 15cm, the roller distance between roller a and roller c is 25cm, and the roller b moves down 30cm from the same plane of roller a and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com