Concentric stranding machine

A technology of concentric stranding and stranding, used in textiles and papermaking, electrical components, textile cables, etc., can solve problems such as production efficiency limitations, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

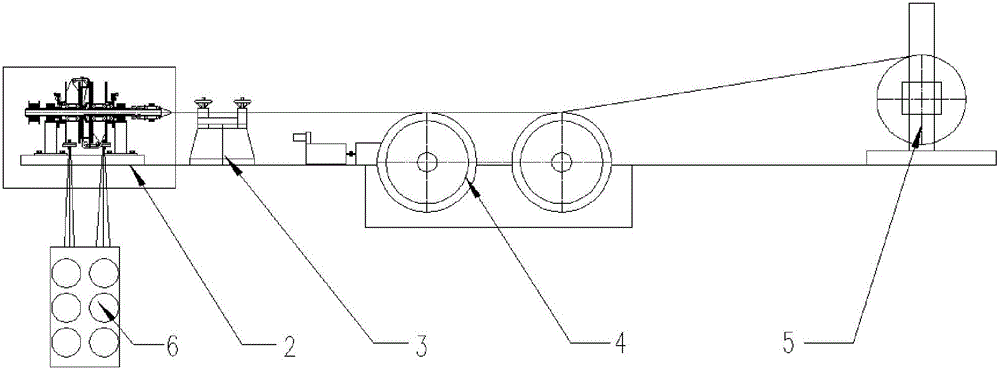

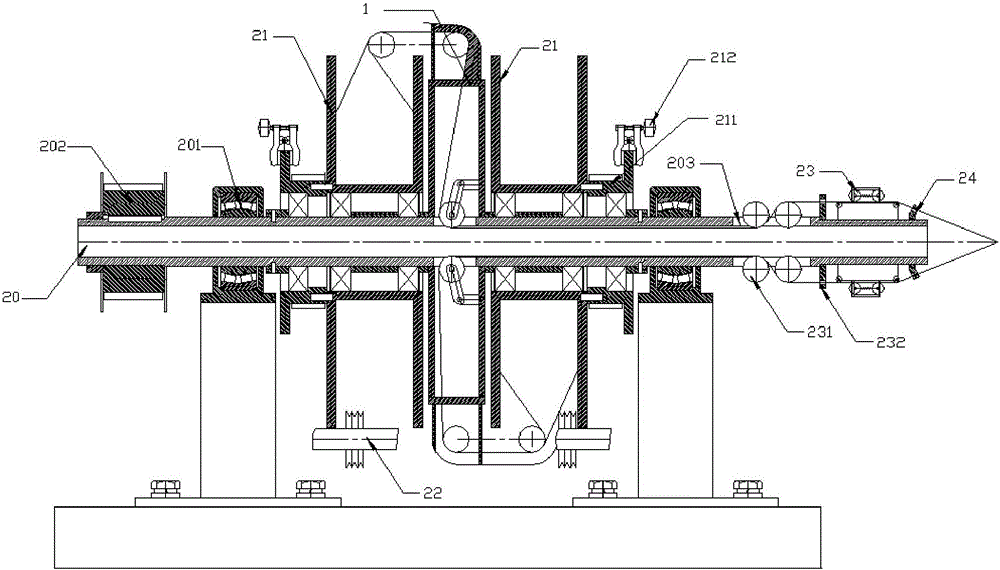

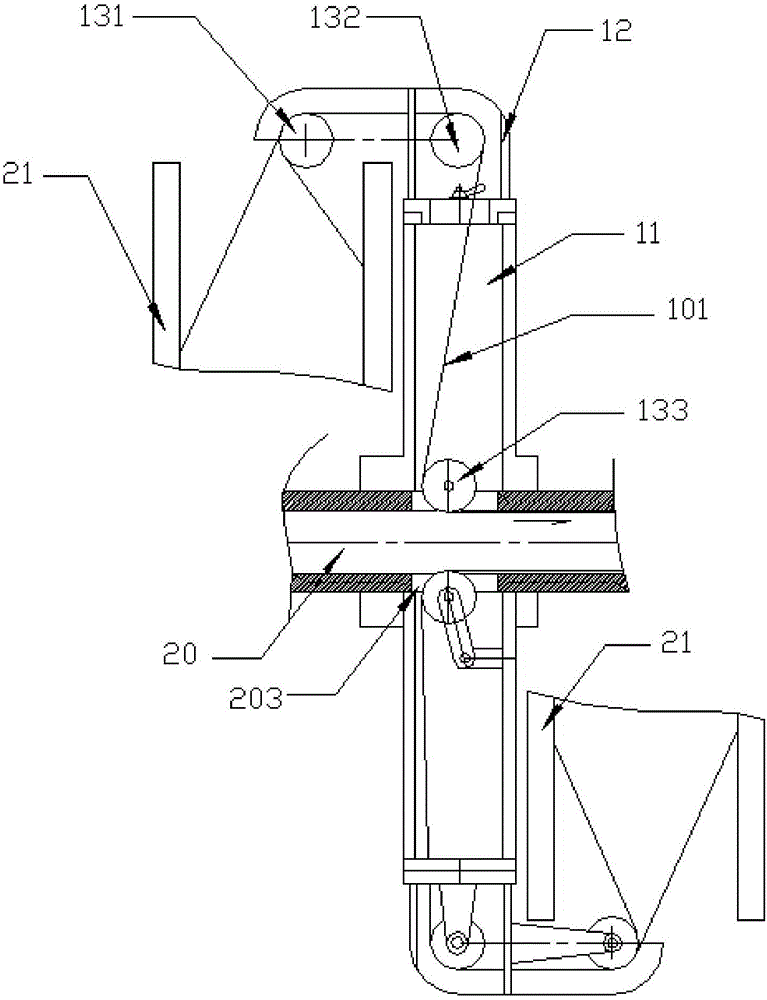

[0019] like figure 1 As shown, a concentric stranding machine includes a pay-off system 6, a stranding system 2, a mold base system 3, a traction system 4, and a take-up system 5. The loop-type monofilament wire drawn by the wire drawing machine is placed on the pay-off system 6, and the pay-off system 6 is released through a tension control device, a guide wheel device, a wire cage device, etc., and then enters after passing through a guide wheel with disc brake control. The stranding system 2 performs rewinding or stranding of the conductors. After the wire is wound, it is released and twisted by the flying wing device, monofilament tension adjustment and other devices, and the fast twisting is completed. The twisted wire is pressed and formed by the mold in the mold base system 3, and the twisted cable after it comes out of the mold The core enters the traction system 4, and the twisted cable core finally enters the take-up system 5 to complete the winding.

[0020] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com