Unit type thermoprinting machine for reeled paper

A technology of roll paper and hot stamping machine, which is applied in the field of multi-position automatic hot stamping equipment of flattening unit, which can solve the problems of complex process and waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

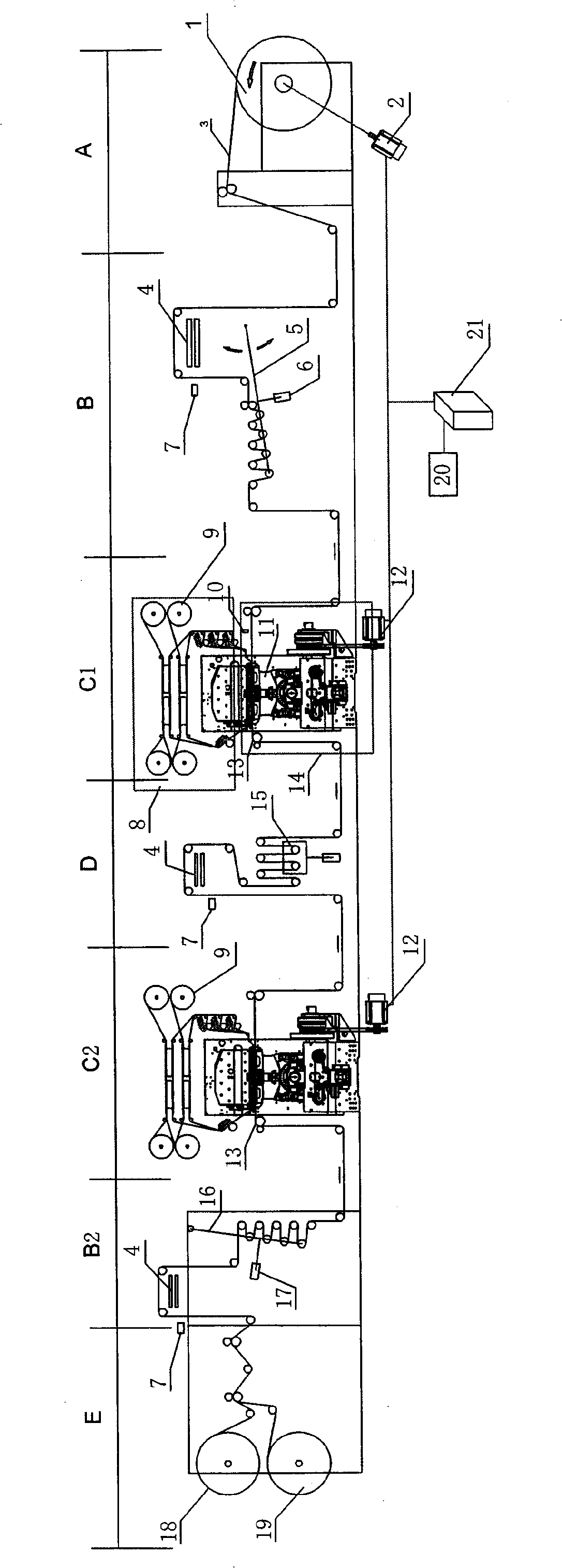

[0015] Embodiment: A roll paper flattening unit-type multi-function automatic hot stamping machine, equipped with multiple sets of hot stamping units, and capable of rewinding at least one rewound web.

[0016] This embodiment first includes a roll paper unwinding device A that enables paper to be continuously supplied to the paper storage device B at the next station. The roll paper unwinding device A has an unwinding motor that drives the roll paper 1 to continuously feed paper. 2.

[0017] A paper storage device B is connected downstream of the roll paper discharge device A, and there is a deviation correction device that controls the vertical direction (horizontal direction) of the paper to ensure that the paper is always kept at the set position during the travel. 4, and a sensor 7 for detecting and feedbacking lateral control; a roller is connected to the deviation correction device 4 and fixed on a swing rod 5, and a constant force device 6 is connected to the swing rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com