Double-purpose rewinding machine for preparing cored toilet paper and coreless toilet paper and method thereof

A technology of toilet paper rolls and toilet paper, which is applied in the field of mechanical processing, can solve the problems of increasing manufacturing costs, affecting production efficiency, and long downtime, and achieves the effects of short downtime, improving production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

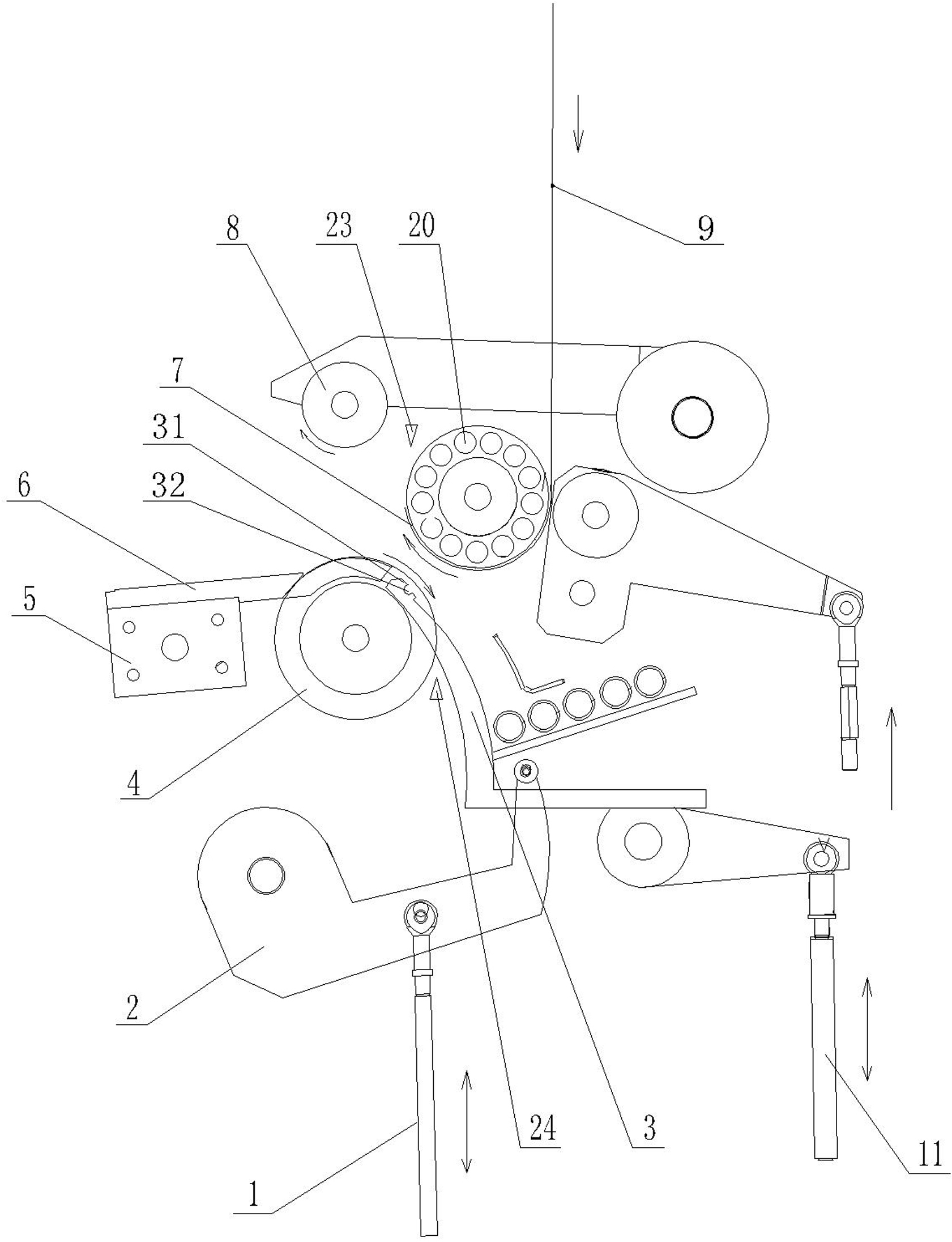

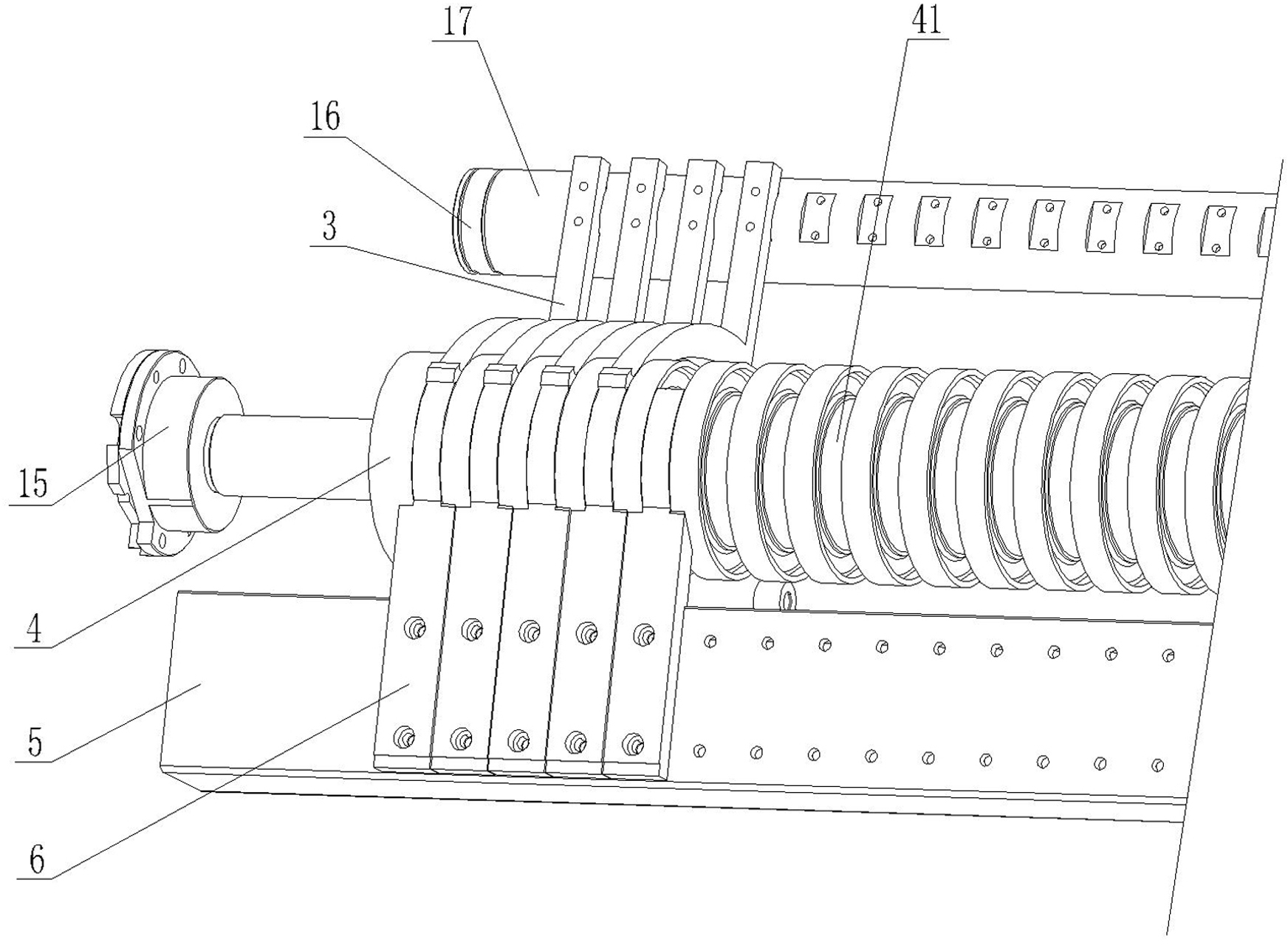

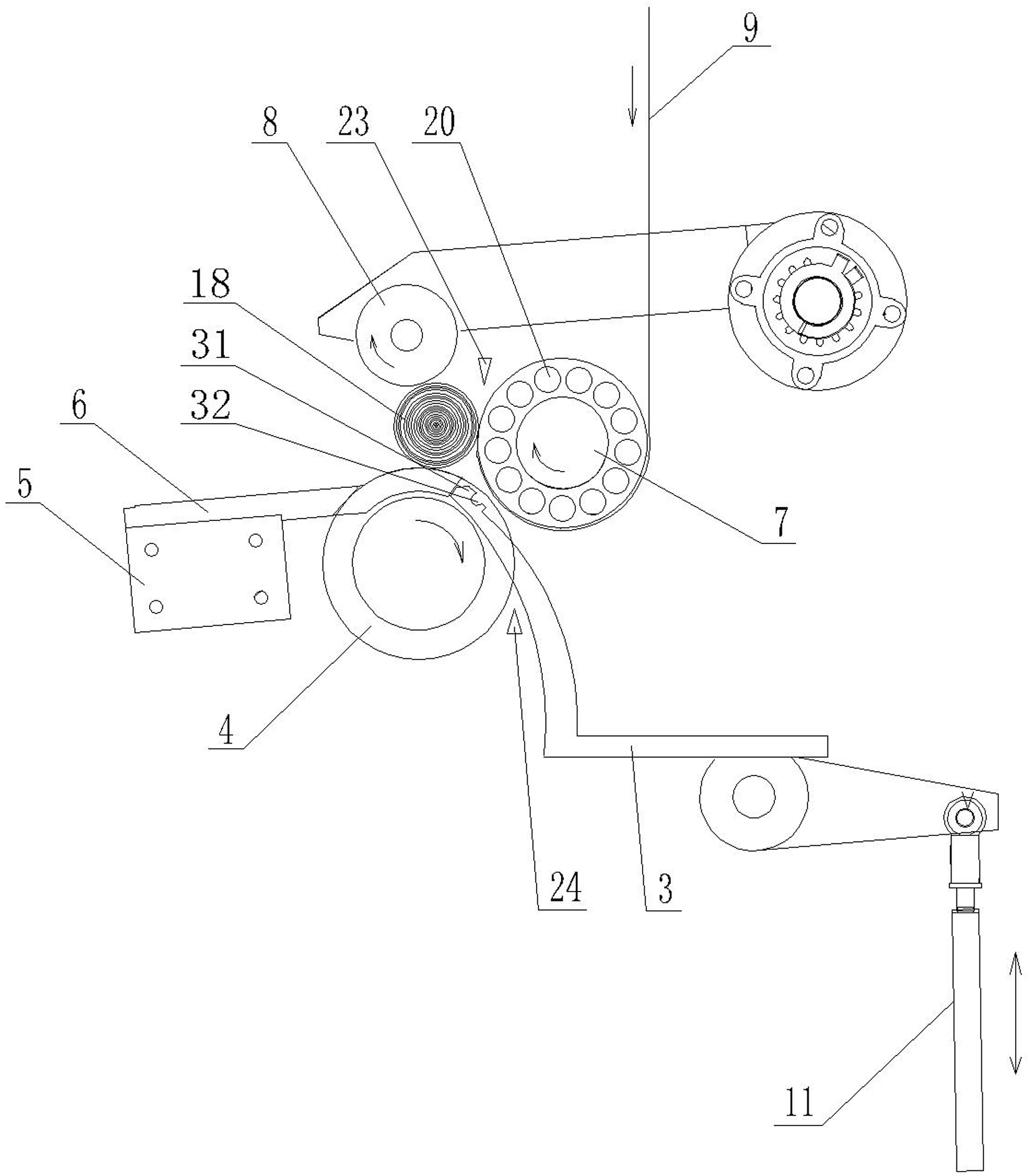

[0034] like Figure 1 to Figure 12 As shown, a dual-purpose rewinding machine for manufacturing coreless toilet paper rolls described in the present invention includes:

[0035] An upper rewinding roller 7, used to drive the feed of the rewound toilet paper base paper 9 from upstream to downstream;

[0036] A lower rewinding roller 4 that rotates in the same direction as the upper rewinding roller 7, and an adjustable gap is formed between the lower rewinding roller 4 and the upper rewinding roller 7, and the rewound toilet paper base paper 9 moves from upstream to downstream direction through the gap;

[0037] A speed-adjustable rewinding press roller 8 used to cut off the above-mentioned toilet paper base paper 9 when the toilet paper roll is wound is completed, and the rewinding press roller 8 is formed between the upper rewinding roller 7 and the lower rewinding roller 4 Rewinding area for toilet paper;

[0038] A paper tube core supply mechanism, including a paper tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com