Tubular stranding machine for cable processing

A stranding machine and tube type technology, which is used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of labor consumption and low efficiency, and achieve the effect of stable operation, guaranteed work efficiency and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

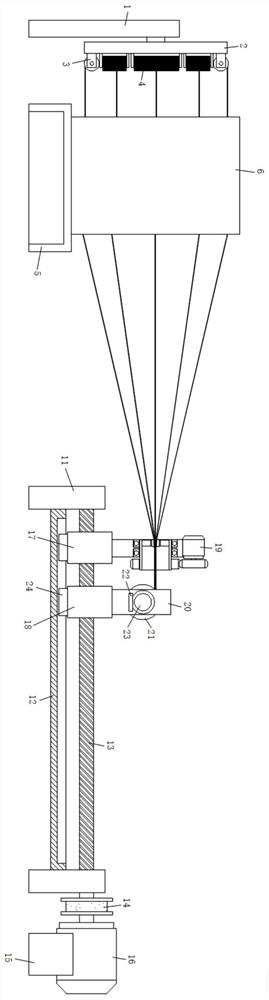

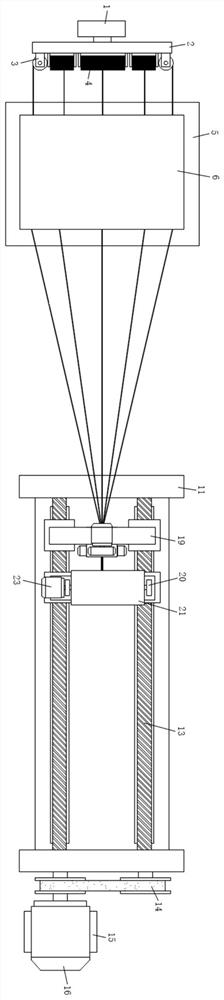

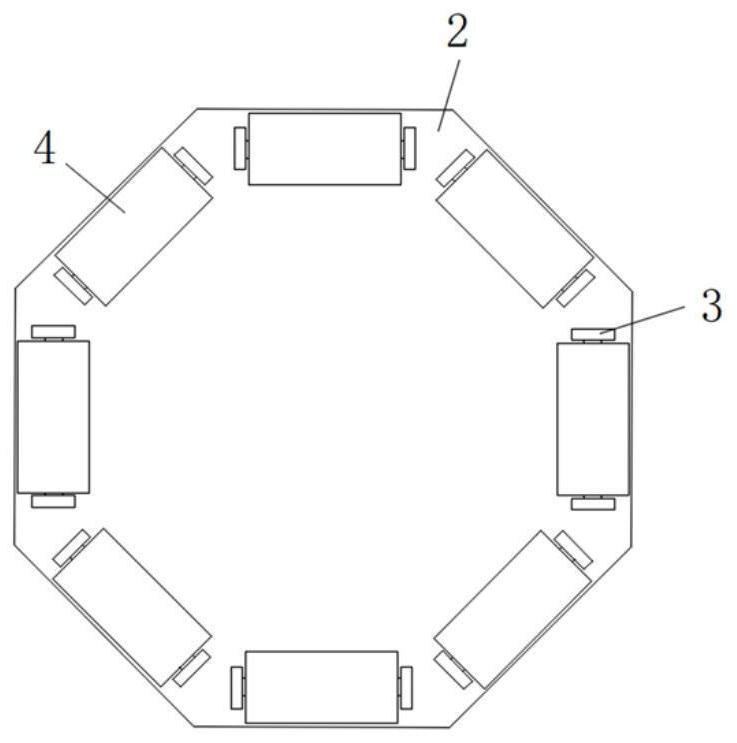

[0031] refer to Figure 1-5 , a tubular stranding machine for cable processing, including a mounting base 1, a pay-off reel 2 is fixedly connected to one side of the upper end of the mount A pay-off roller 4 is connected between the blocks 3, and a mounting frame 5 is arranged on one side of the mounting base 1, and a straightening block 6 is fixed on the top surface of the mounting frame 5, and a cylindrical hole is provided on the extension of the straightening block 6 close to the mounting base 1 7. The inner wall of the cylindrical hole 7 is fixed with a heating sheet 8, and the other end of the straightening block 6 is also provided with a rectangular groove 9 at the extension position. The rectangular groove 9 is connected with the cylindrical hole 7, and the inner walls of the front and rear sides of the rectangular groove 9 rotate The straightening roller 10 is connected, and the side of the mounting frame 5 facing away from the mounting base 1 is also provided with a ...

Embodiment 2

[0034] Such as figure 1 , 2As shown in and 5, this embodiment is basically the same as Embodiment 1. Preferably, the twisting mechanism 19 includes a fixed plate 191, and the middle part of the fixed plate 191 is rotatably connected with a twisting barrel 192, and the twisting barrel 192 is close to the side of the straightening block 6 The inner wall is fixed with electric telescopic rods 193 by screws. There are three electric telescopic rods 193 which are evenly distributed on the inner wall of one side of the twisting tube 192 in a ring shape. The output ends of the electric telescopic rods 193 are fixed with extrusion blocks 194 by screws. , one end of the twisted wire barrel 192 deviates from the straightening block 6 and extends to the outside of the fixed plate 191 and is fixed with an outer ring gear 195 on the outer wall. The screw is fixedly connected with a driving gear 197 , and the driving gear 197 is meshed with the outer ring gear 195 .

[0035] In this embod...

Embodiment 3

[0037] Such as figure 1 with 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the front and rear sides of the bottom ends of the first installation strip 17 and the second installation strip 18 are all fixedly connected with the limit block 24, and the front and rear sides of the top of the support plate 12 are also provided with a limit slot. The limiting blocks 24 are all slidably connected in the limiting grooves.

[0038] In this embodiment, the first installation bar 17 and the second installation bar 18 are connected to the support plate 12 through the limit block 24, so that the translation of the first installation bar 17 and the second installation bar 18 is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com