Internal supporting and external hooping non-fixing-and-spot-welding girth welder applicable to one-side welding with back formation

A technology of single-sided welding, double-sided welding, and circular seam welding, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. and other problems, to achieve high synchronization, improve welding quality, and achieve the effect of seamless docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

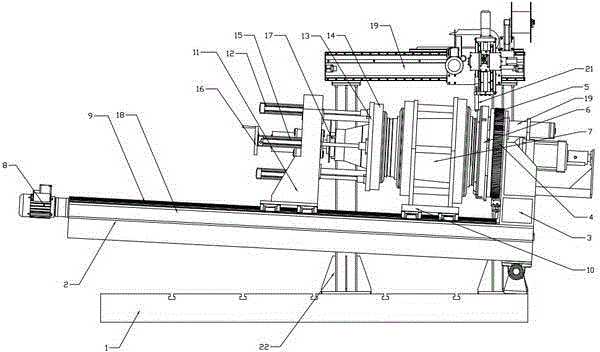

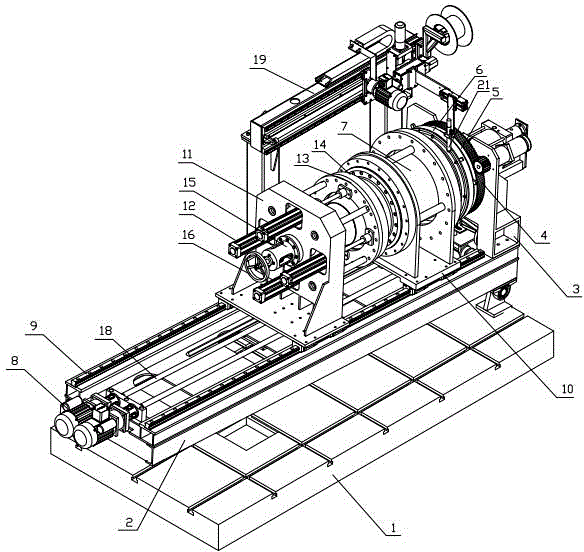

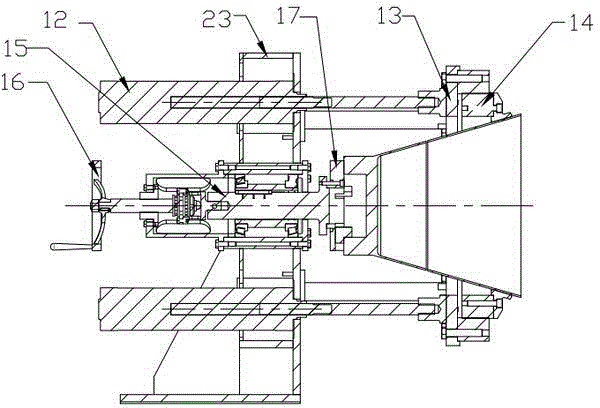

[0045] A non-point-fixed ring seam welding machine with inner support and outer hoop suitable for single-sided welding and double-sided forming includes a base platform 1, and a paired machine base 2 that can rotate around a support point is installed above the base platform 1; The right end of the upper surface of the group pair machine base 2 is equipped with a fixed revolving base 3, the fixed revolving base 3 is connected with the inner supporting device 7 and the first clamping mechanism 6, and the upper end of the fixed revolving base 3 is equipped with a first driving motor 8 A group of two linear slide rails 9 are installed on the upper surface of the base 2, the linear slide rail 9 is equipped with a moving support 10 and a moving tailstock 11, and the moving support 10 is equipped with the first One accommodating cavity, the first workpiece cover that can rotate relative to the moving support 10 is housed in the first accommodating cavity; two first cylinders 12 are i...

Embodiment 2

[0049] A non-point-fixed ring seam welding machine with inner support and outer hoop suitable for single-sided welding and double-sided forming includes a base platform 1, and a paired machine base 2 that can rotate around a support point is installed above the base platform 1; The right end of the upper surface of the group pair machine base 2 is equipped with a fixed revolving base 3, the fixed revolving base 3 is connected with the inner supporting device 7 and the first clamping mechanism 6, and the upper end of the fixed revolving base 3 is equipped with a first driving motor 8 A group of two linear slide rails 9 are installed on the upper surface of the base 2, the linear slide rail 9 is equipped with a moving support 10 and a moving tailstock 11, and the moving support 10 is equipped with the first One accommodating cavity, the first workpiece cover that can rotate relative to the moving support 10 is housed in the first accommodating cavity; two first cylinders 12 are i...

Embodiment 3

[0059] A non-point-fixed ring seam welding machine with inner support and outer hoop suitable for single-sided welding and double-sided forming includes a base platform 1, and a paired machine base 2 that can rotate around a support point is installed above the base platform 1; The right end of the upper surface of the group pair machine base 2 is equipped with a fixed revolving base 3, the fixed revolving base 3 is connected with the inner supporting device 7 and the first clamping mechanism 6, and the upper end of the fixed revolving base 3 is equipped with a first driving motor 8 A group of two linear slide rails 9 are installed on the upper surface of the base 2, the linear slide rail 9 is equipped with a moving support 10 and a moving tailstock 11, and the moving support 10 is equipped with the first One accommodating cavity, the first workpiece cover that can rotate relative to the moving support 10 is housed in the first accommodating cavity; two first cylinders 12 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com