BN ion door and manufacturing method thereof

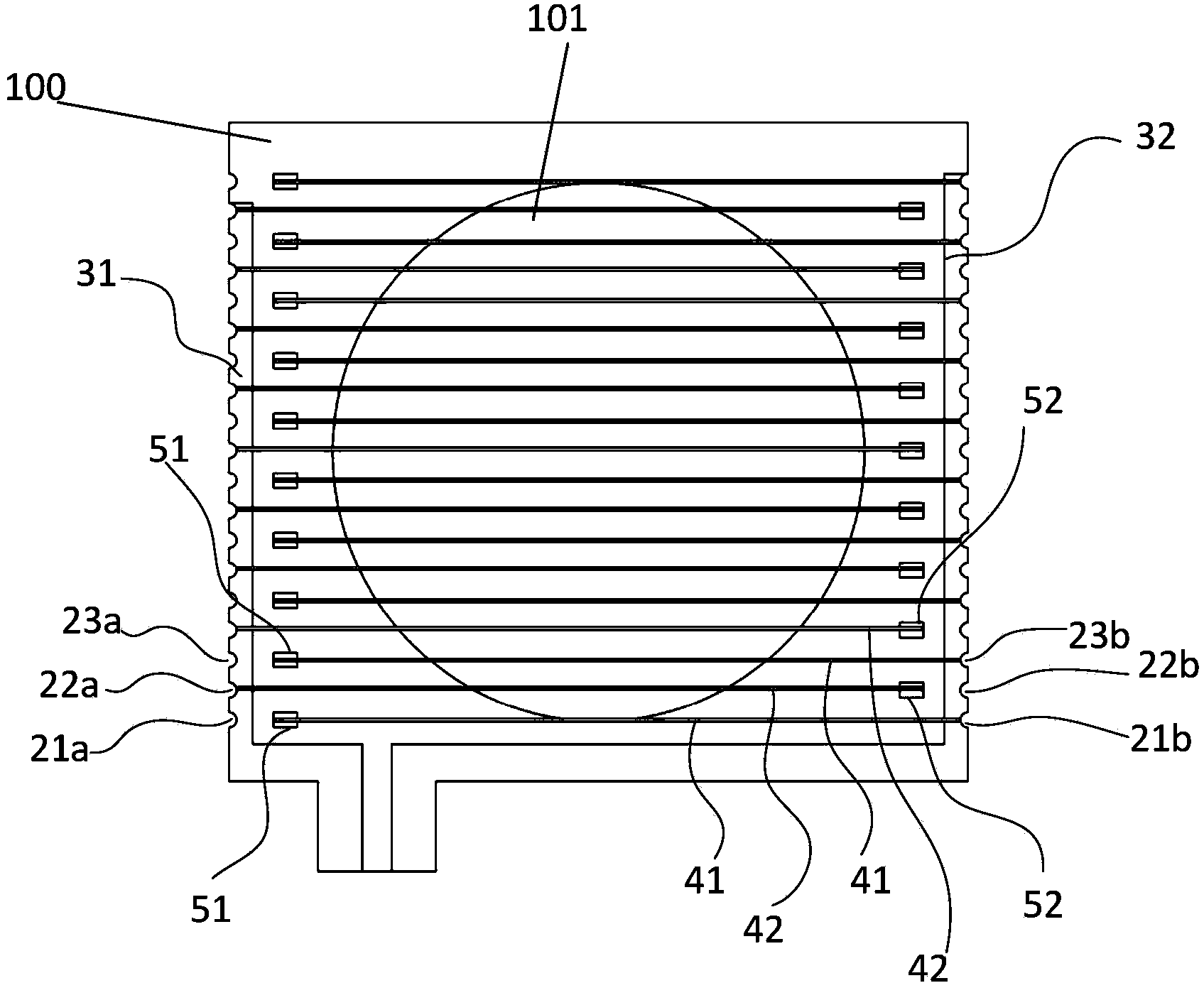

A manufacturing method and ion gate technology, which are applied in the field of analytical instruments and can solve problems such as instability and uneven radial electric field of BN ion gates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

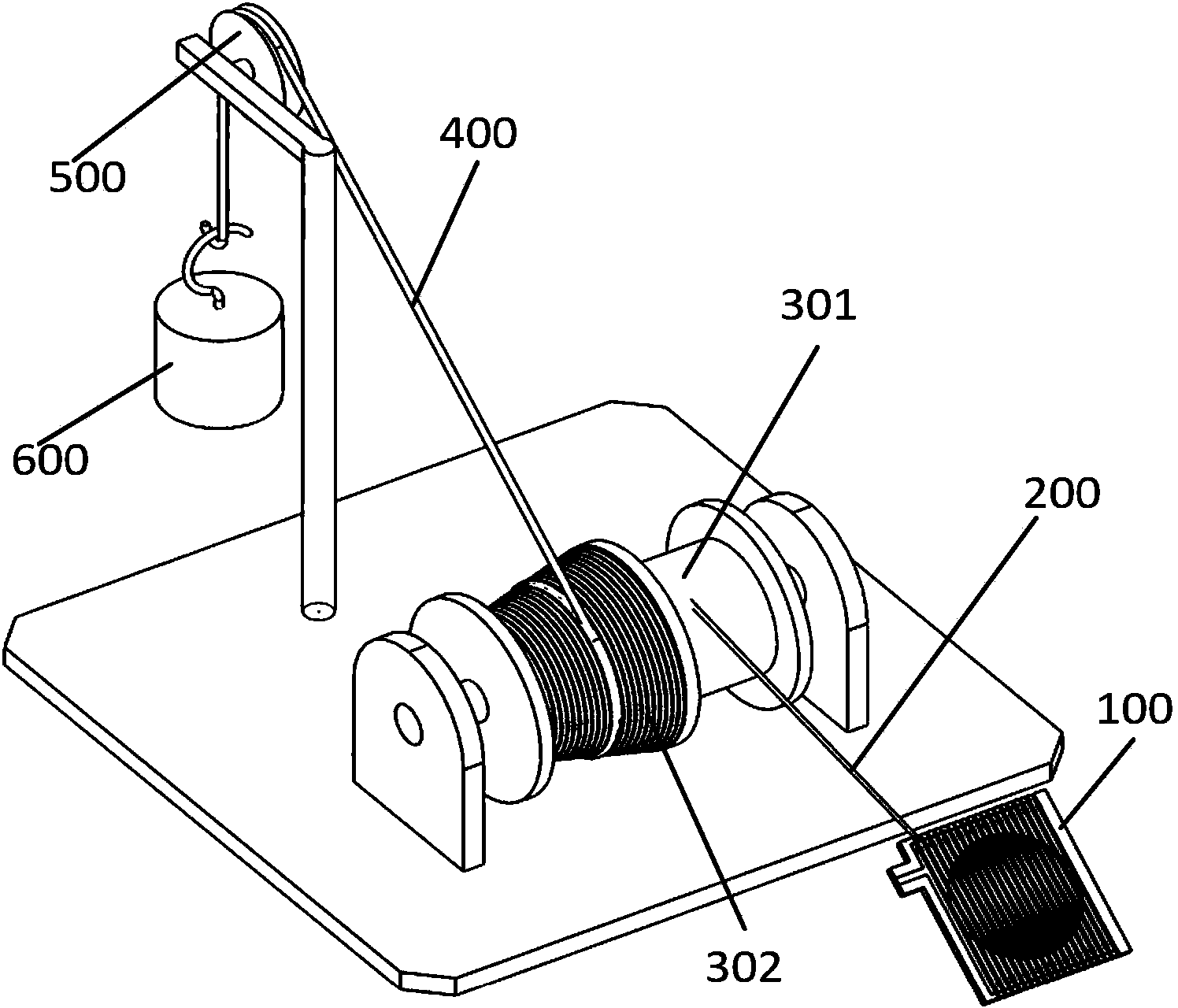

[0085] The present embodiment provides a method for manufacturing a BN ion gate, the method comprising the following steps:

[0086] S1, providing an insulating substrate and metal wires;

[0087]S2. Provide a gradual preload to act on the metal wire, so that the metal wire is wound on the insulating substrate, so as to form a plurality of parallel and equidistantly arranged metal wires on the same surface of the insulating substrate segment, and a plurality of the wire segments form a first wire group and a second wire group that are alternately arranged and insulated from each other, and each of the wire segments has the same internal tension; wherein each of the metal The wire segments require different pre-tightening forces, and the pre-tightening forces gradually decrease from the first wire segment to the last wire segment, so that the i-th wire segment to be wound is subject to its corresponding pre-tightening force. The stretched length of the insulating substrate is ...

Embodiment 2

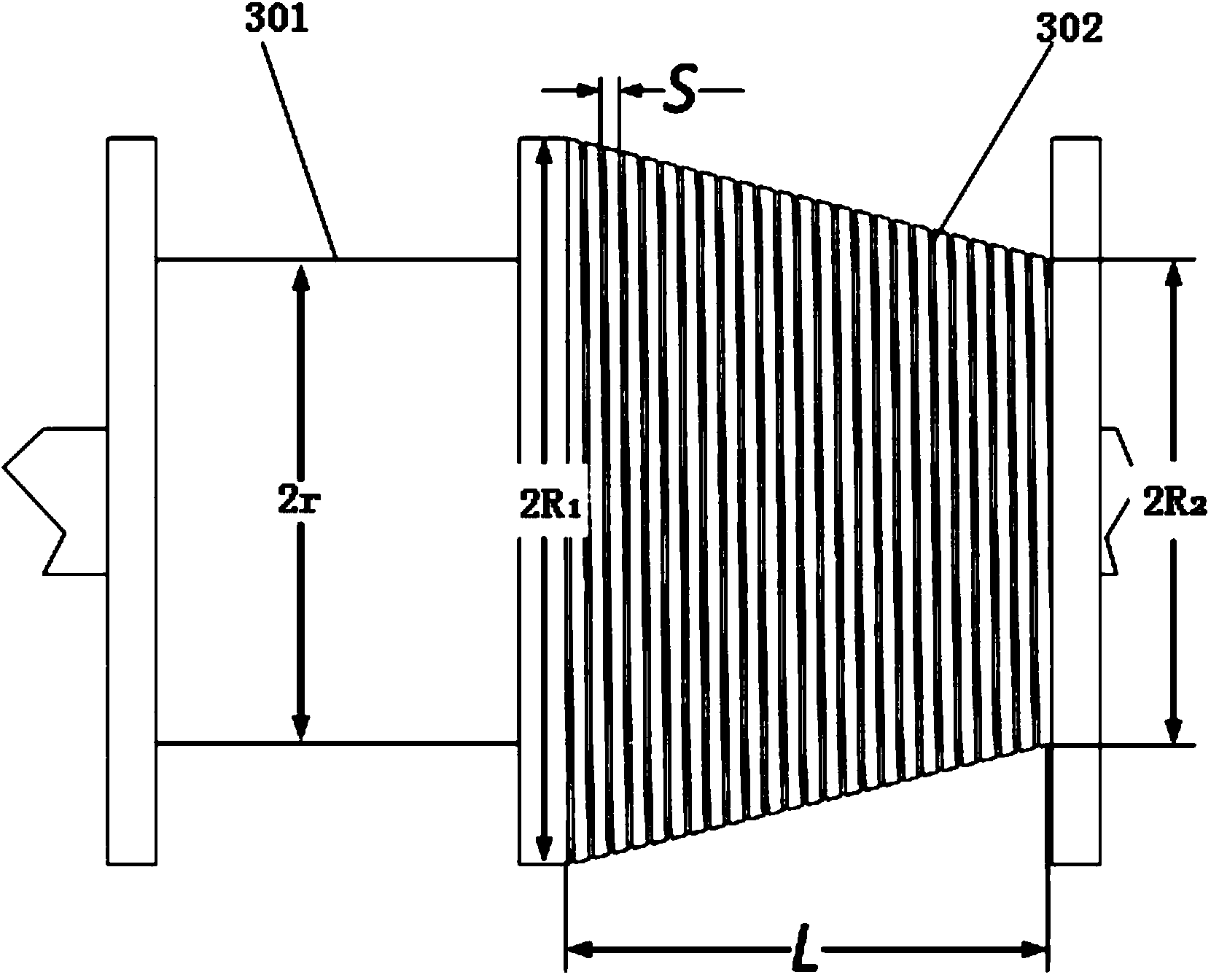

[0122] The difference between the manufacturing method of the BN ion gate provided in this embodiment and that of Embodiment 1 is that the tension conversion mechanism that provides the pre-tightening force provides a gradual pre-tightening force by continuously changing the quality of the weights, so the tension conversion in this embodiment Exist following difference in mechanism and embodiment 1: as Figure 5 As shown, the tension conversion shaft includes a first cylinder 301a and a second cylinder 302a for winding the metal wire 200, and the tension wire of the weight is fixed on the second cylinder 302a and can be wound on the cylindrical surface thereof. In a preferred solution, there is a protruding circular partition plate between the cylinder surface of the first cylinder 301a and the cylinder surface of the second cylinder 302a.

[0123] Based on the above differences, in this embodiment, the parameters of the first cylinder and the second cylinder of the tension co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com