Patents

Literature

84 results about "Proportional counter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The proportional counter is a type of gaseous ionization detector device used to measure particles of ionizing radiation. The key feature is its ability to measure the energy of incident radiation, by producing a detector output pulse that is proportional to the radiation energy absorbed by the detector due to an ionizing event; hence the detector's name. It is widely used where energy levels of incident radiation must be known, such as in the discrimination between alpha and beta particles, or accurate measurement of X-ray radiation dose.

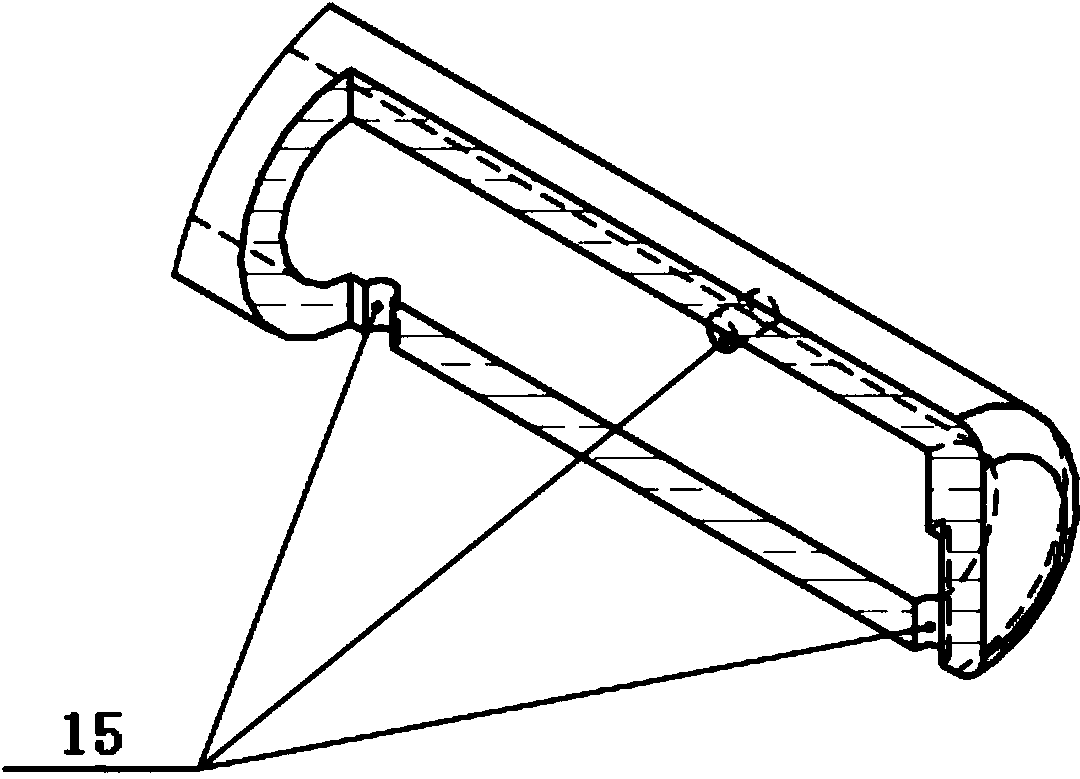

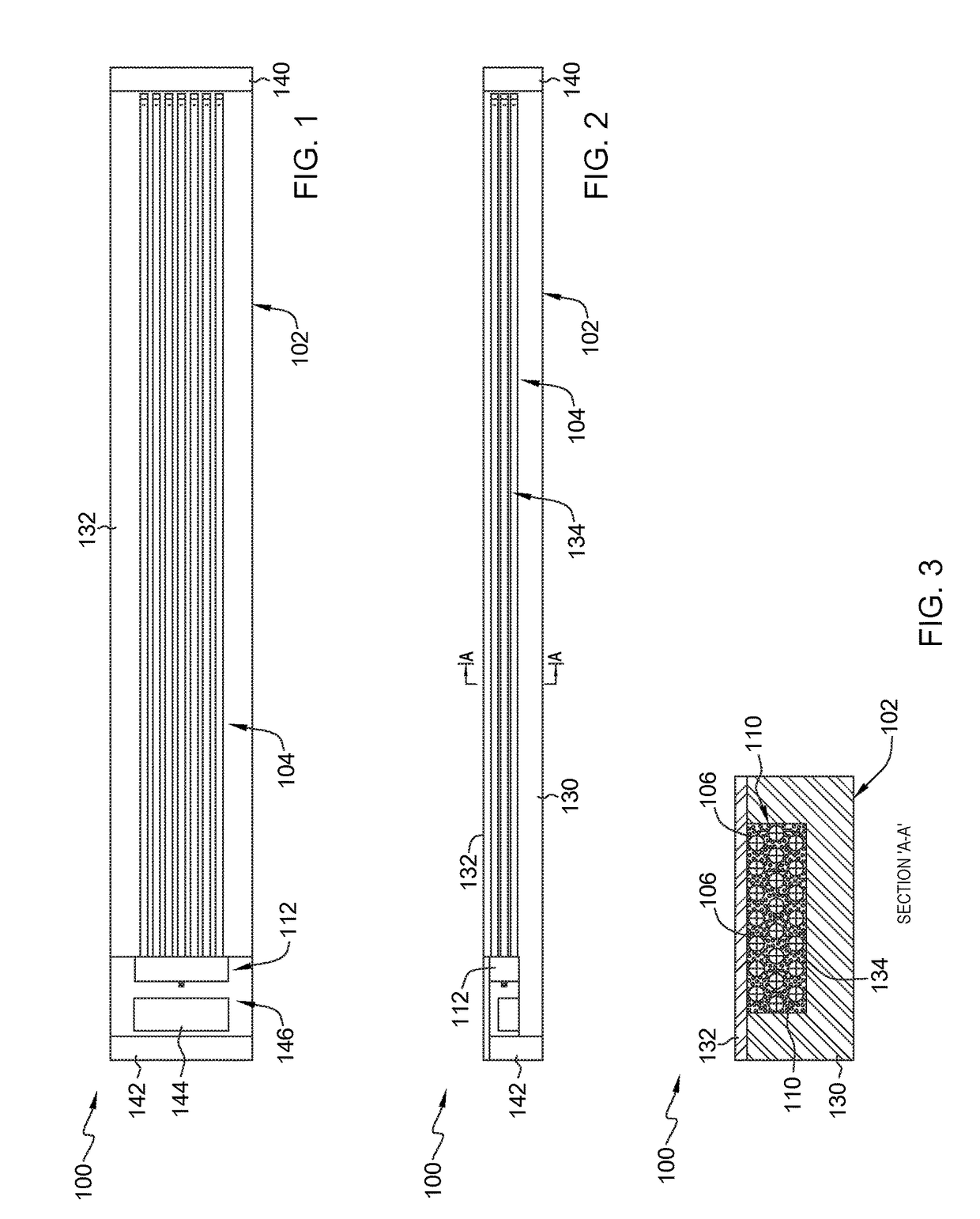

Neutron Energy Spectrometer

ActiveUS20110049380A1Material analysis by optical meansNeutron radiation measurementEngineeringHelium-3

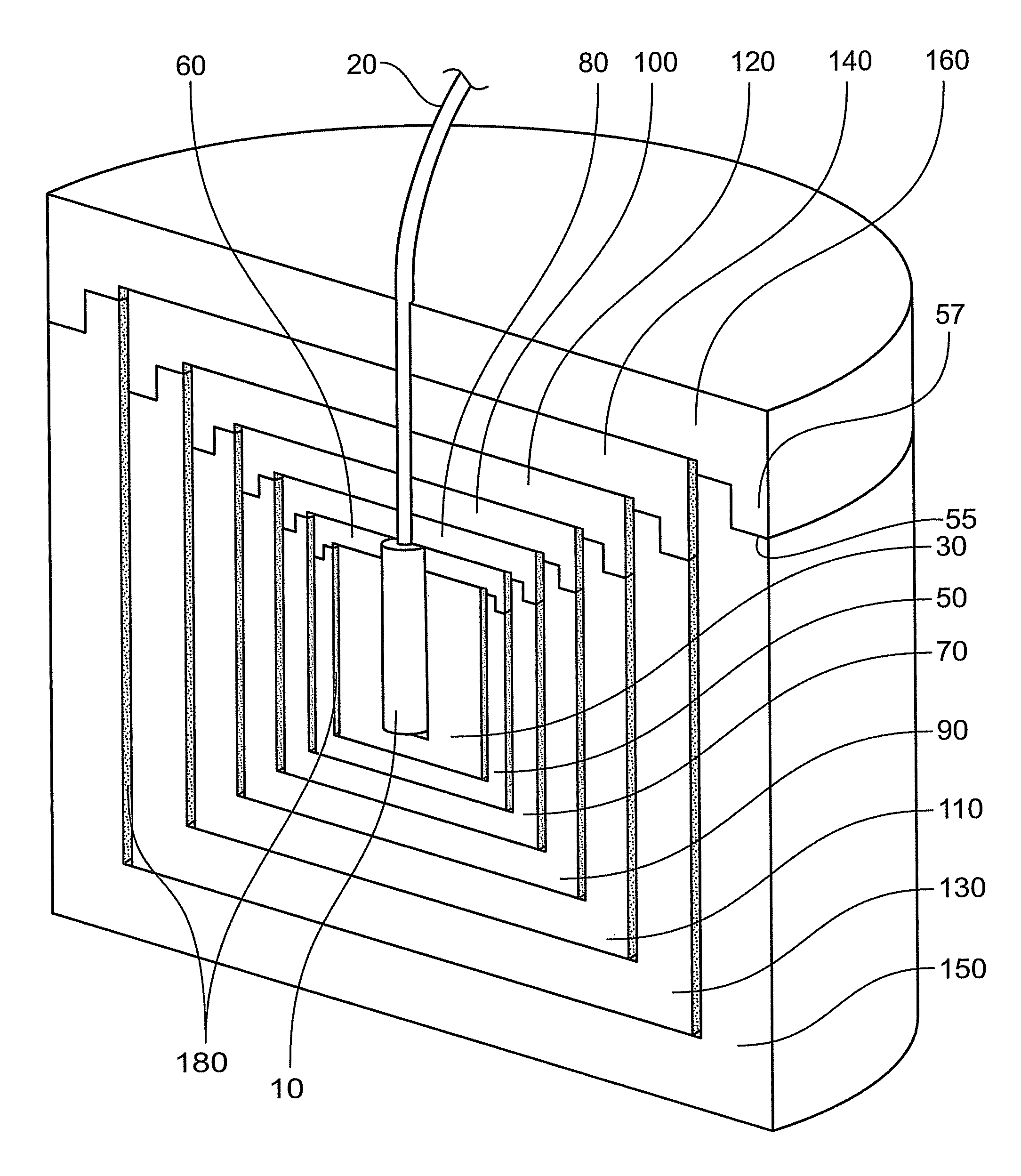

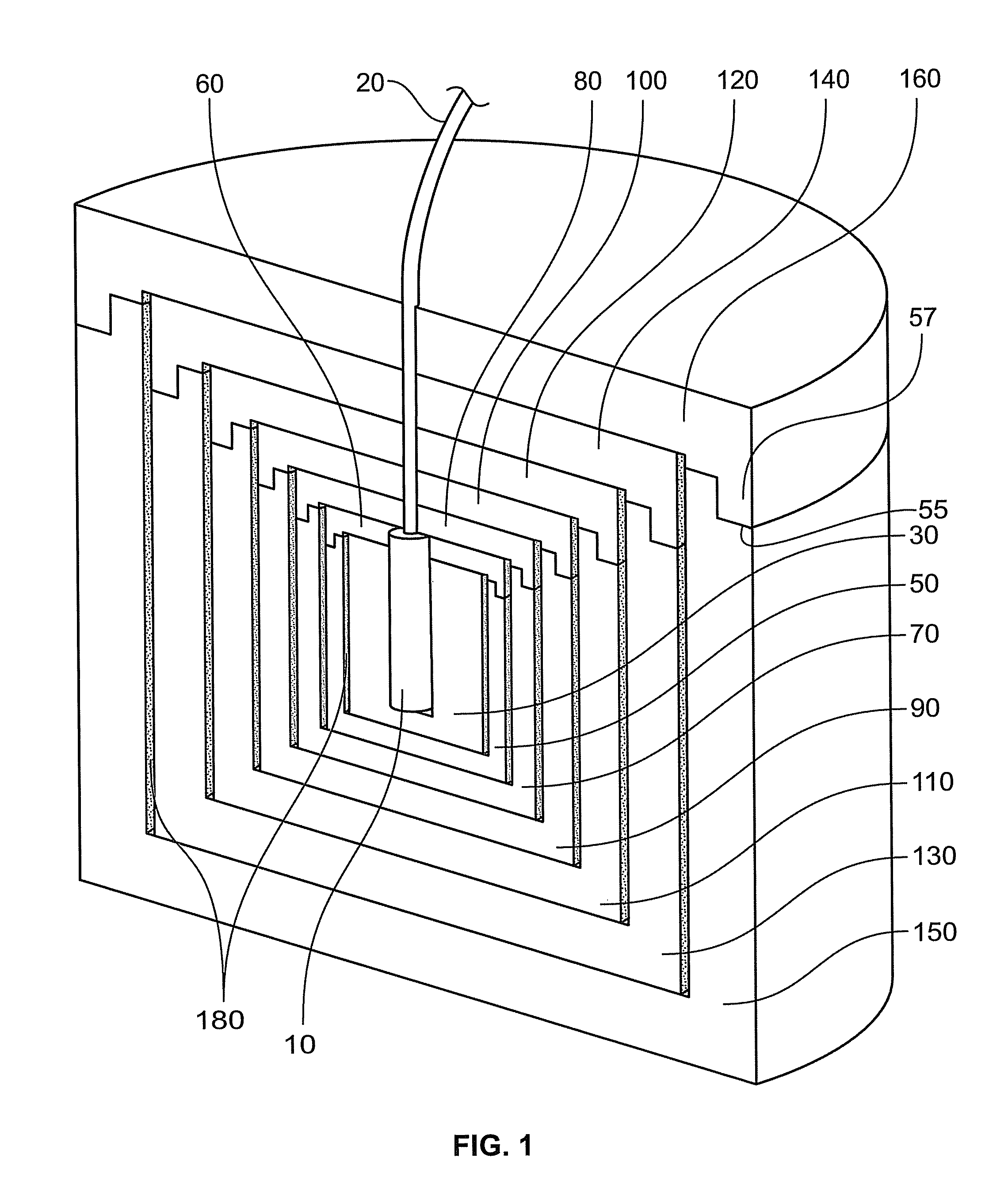

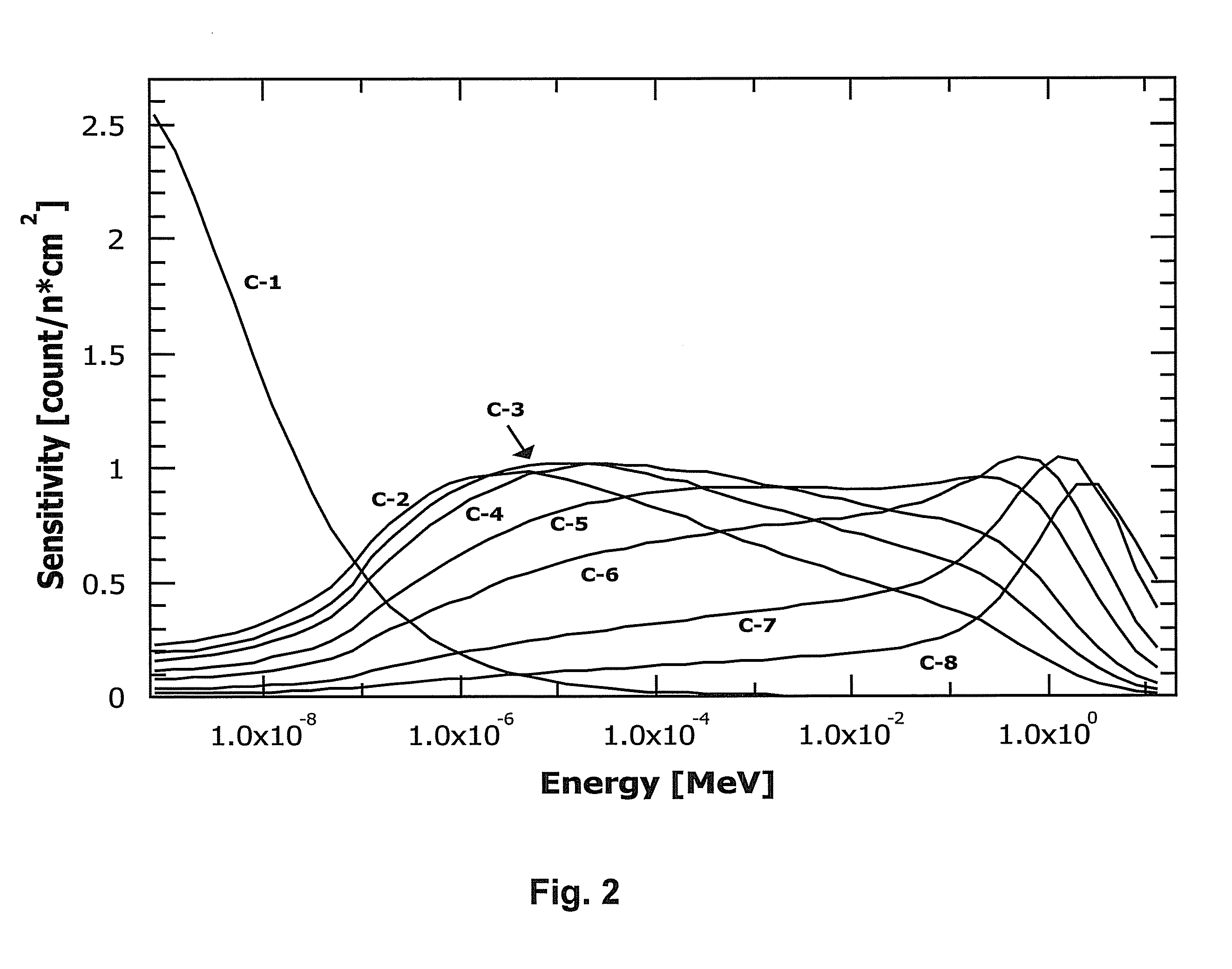

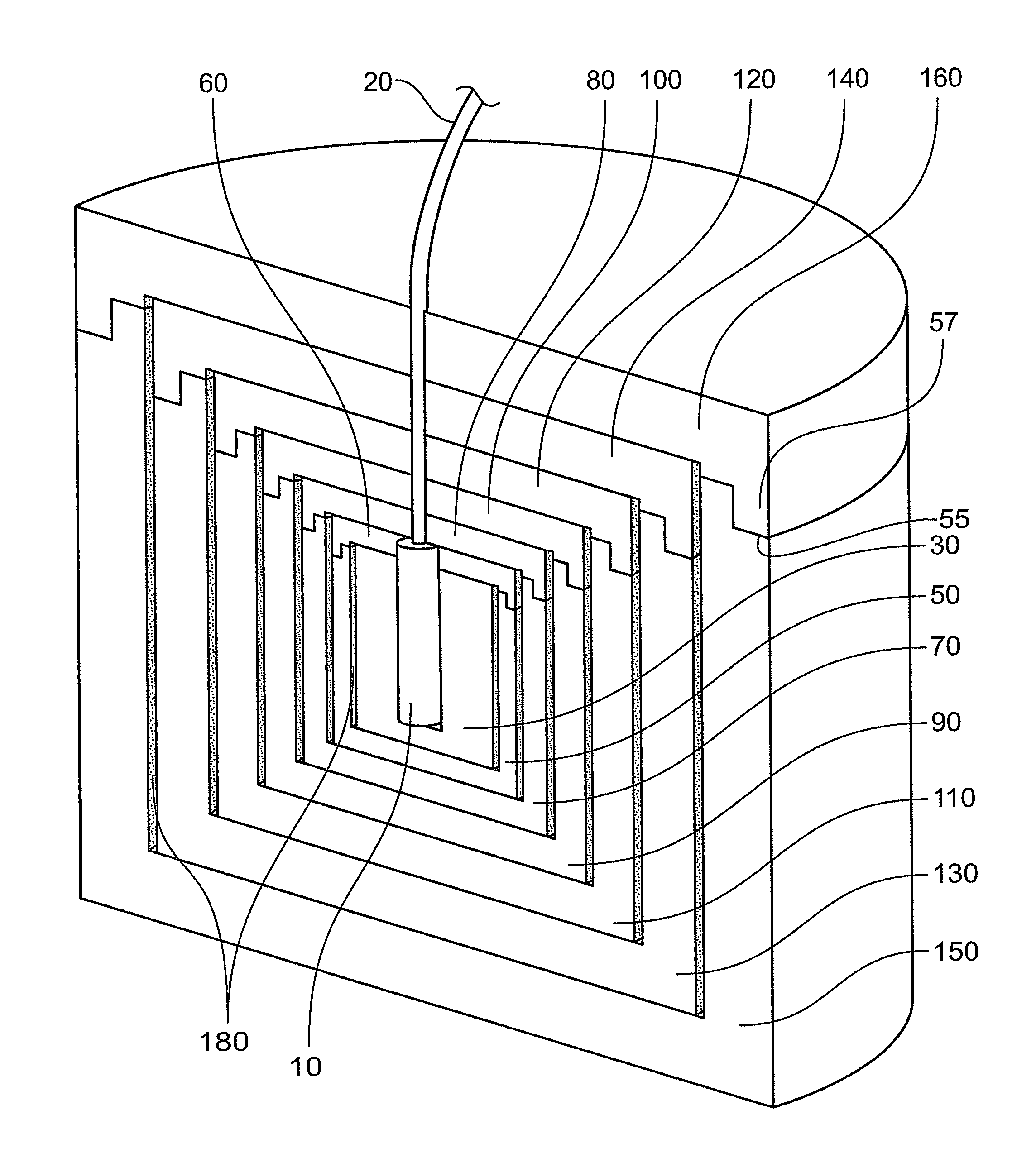

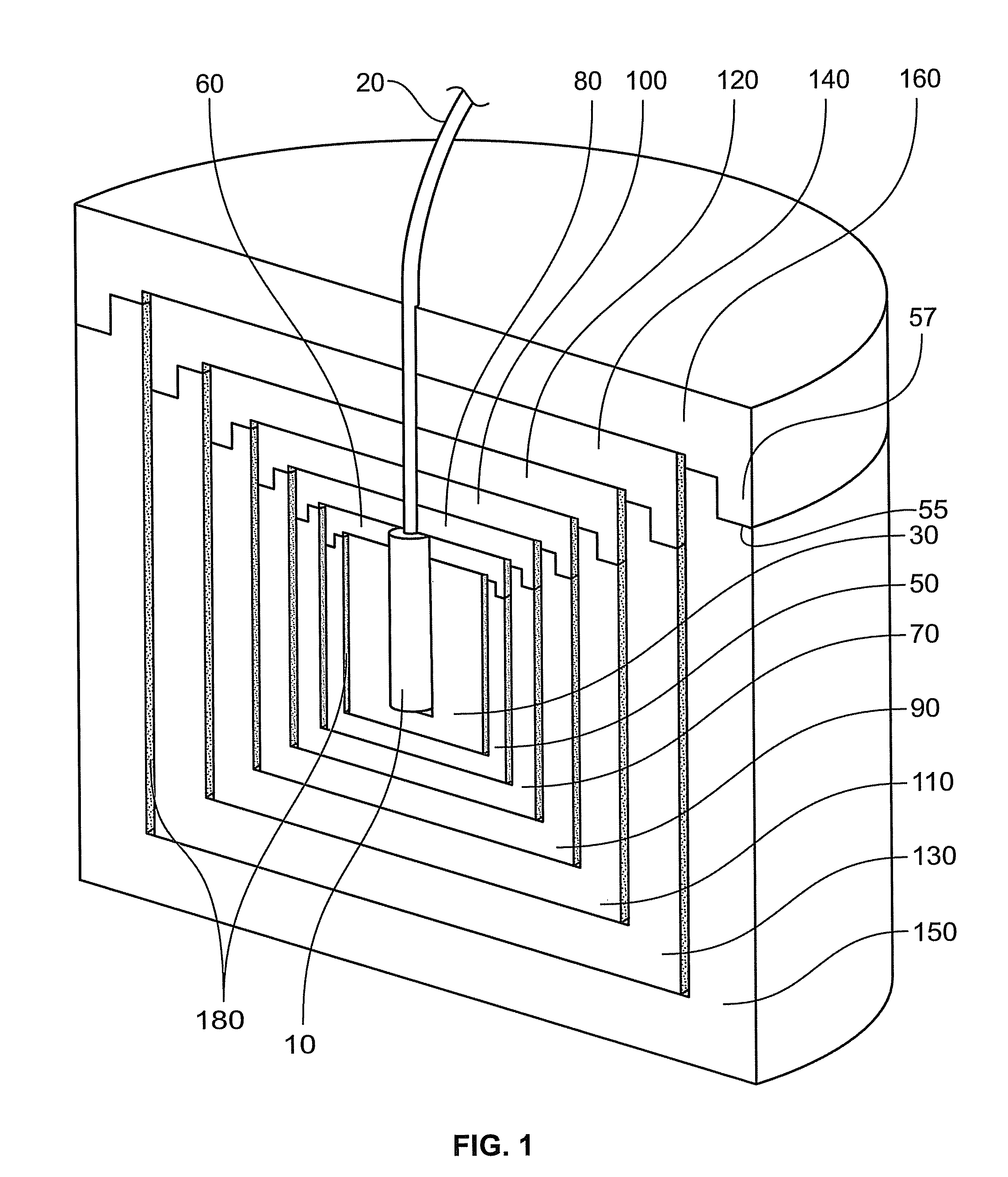

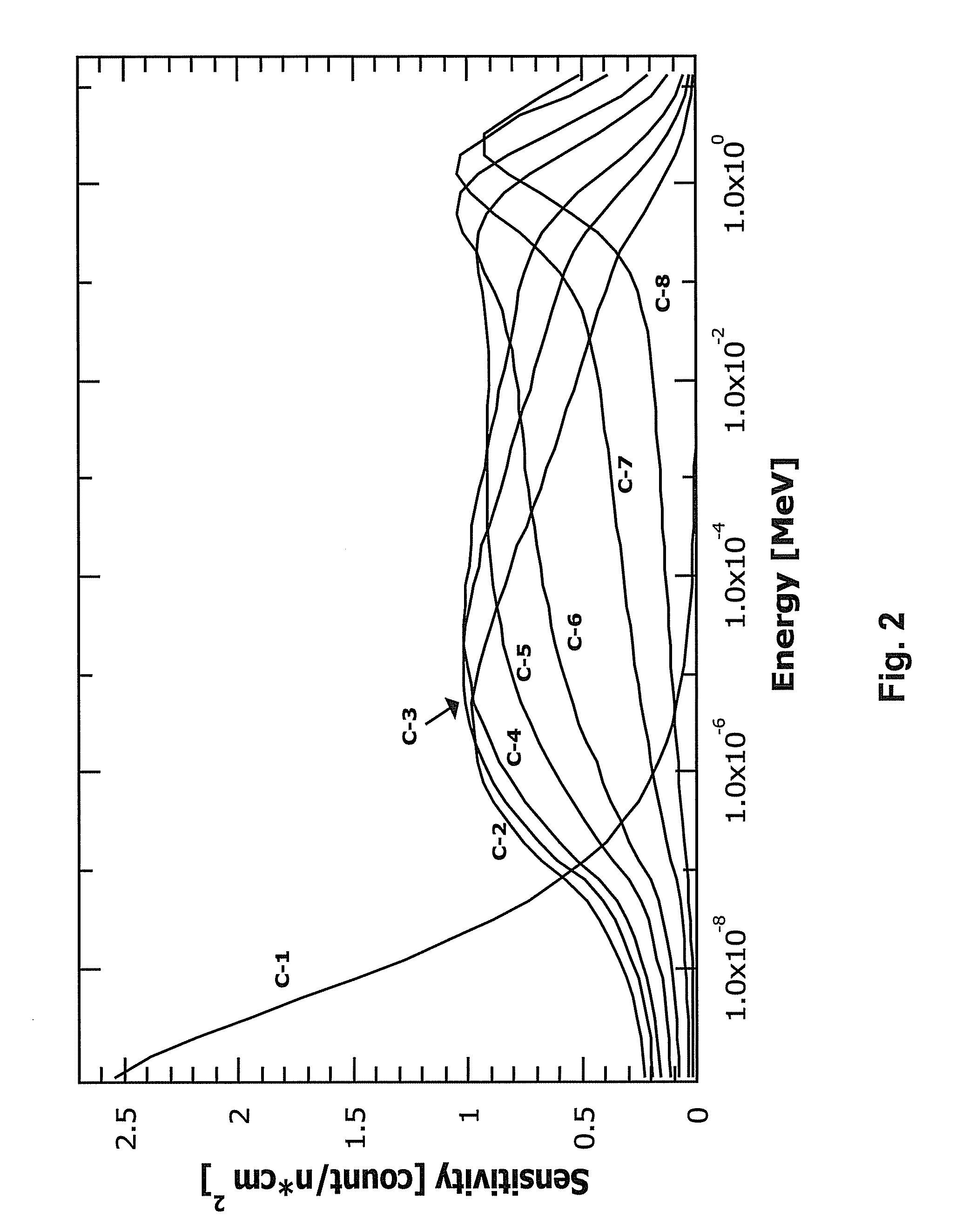

A neutron spectrometer is disclosed, which consists of a Helium-3 proportional counter connected by cable to signal and data processing circuits, and a series of moderator shells and moderator lids. The series of cylindrical moderator shells are designed to fit within one another, like Russian Matryoshka dolls, with the counter at the center. Small air gaps are introduced between the shells so that removal of one shell from another is facilitated. The counter is placed within the smallest cylindrical moderator shell, and then a circular lid matching the smallest shell is placed on the opening of the first shell to close the first shell. This first closed shell is then placed within a second shell, which shell is closed with its corresponding circular lid. The cable is routed through the series of shells. A method for using the invention is also disclosed, wherein the counter reading is taken from the fully-assembled neutron spectrometer. Then the outer cylindrical shell and circular lid pair is removed, and another measurement of the counter is recorded. This is continued until the last shell is removed, and a measurement is recorded using the bare counter.

Owner:3833364 CANADA OPERATING DETEC

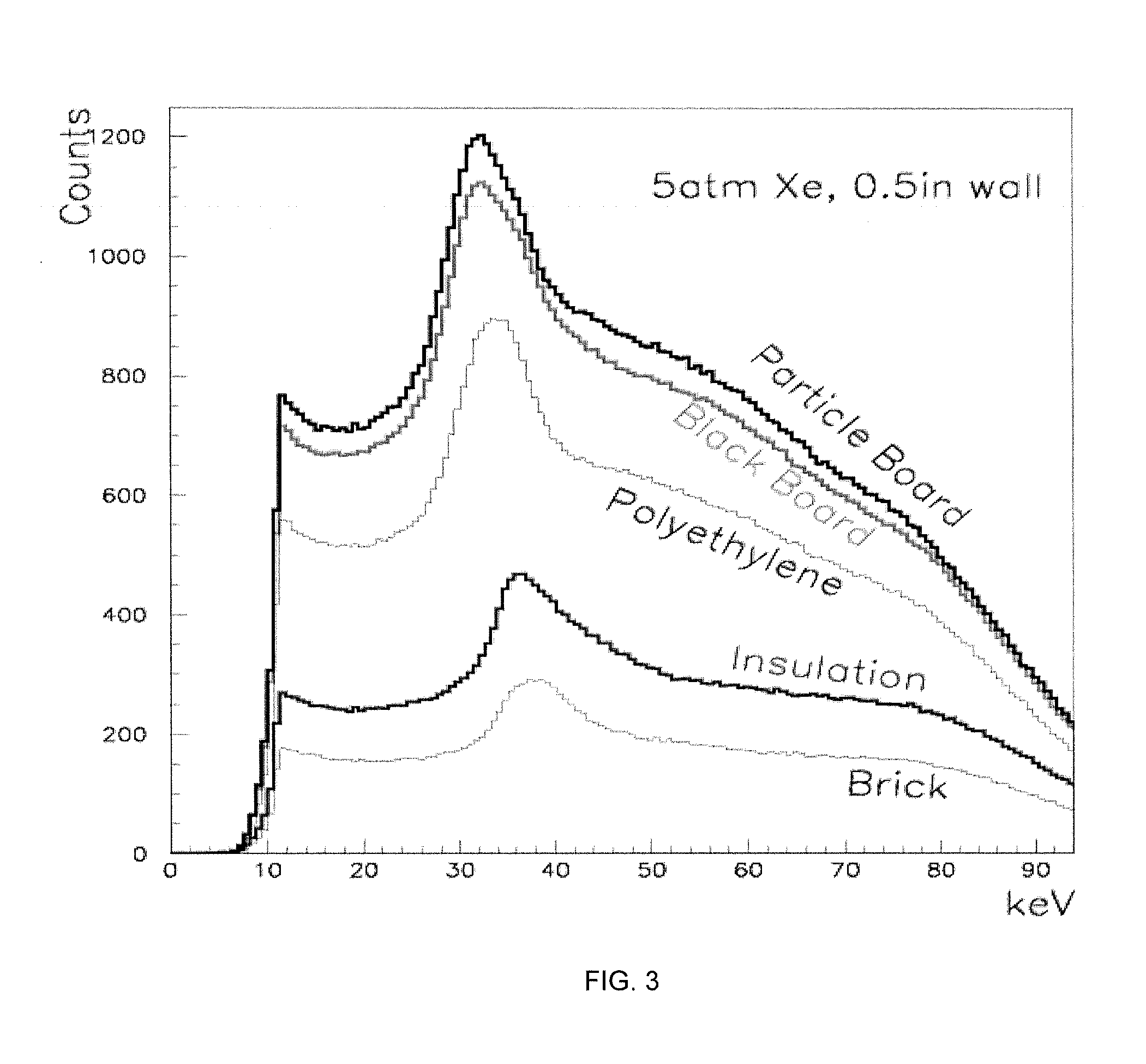

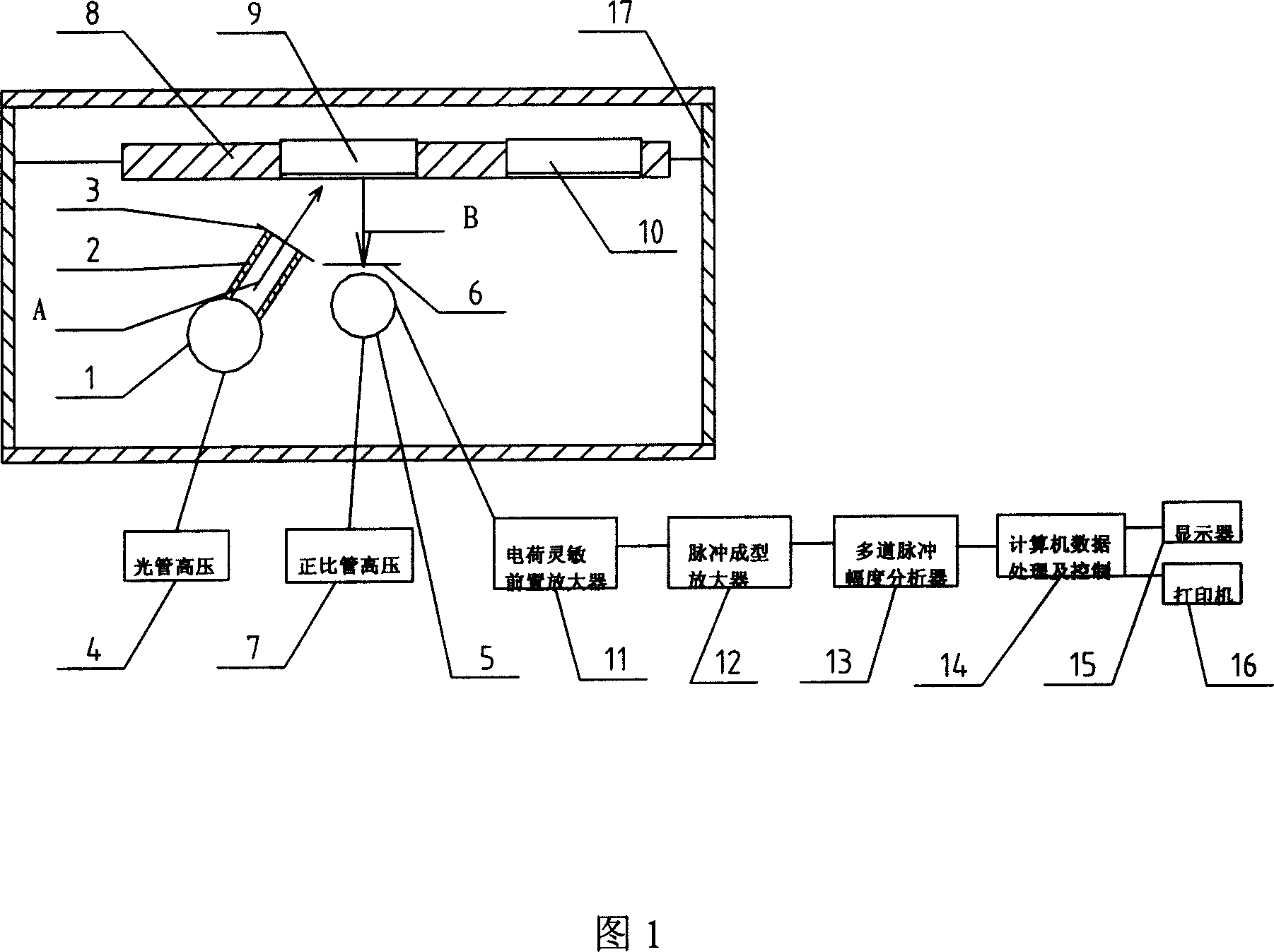

Device and method for measuring coating by using X-ray fluorescence spectrometer

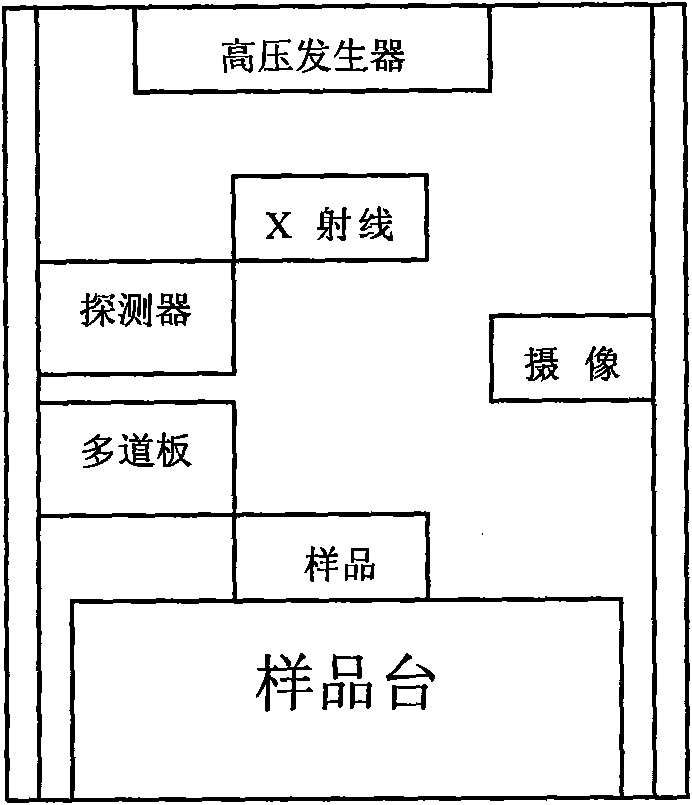

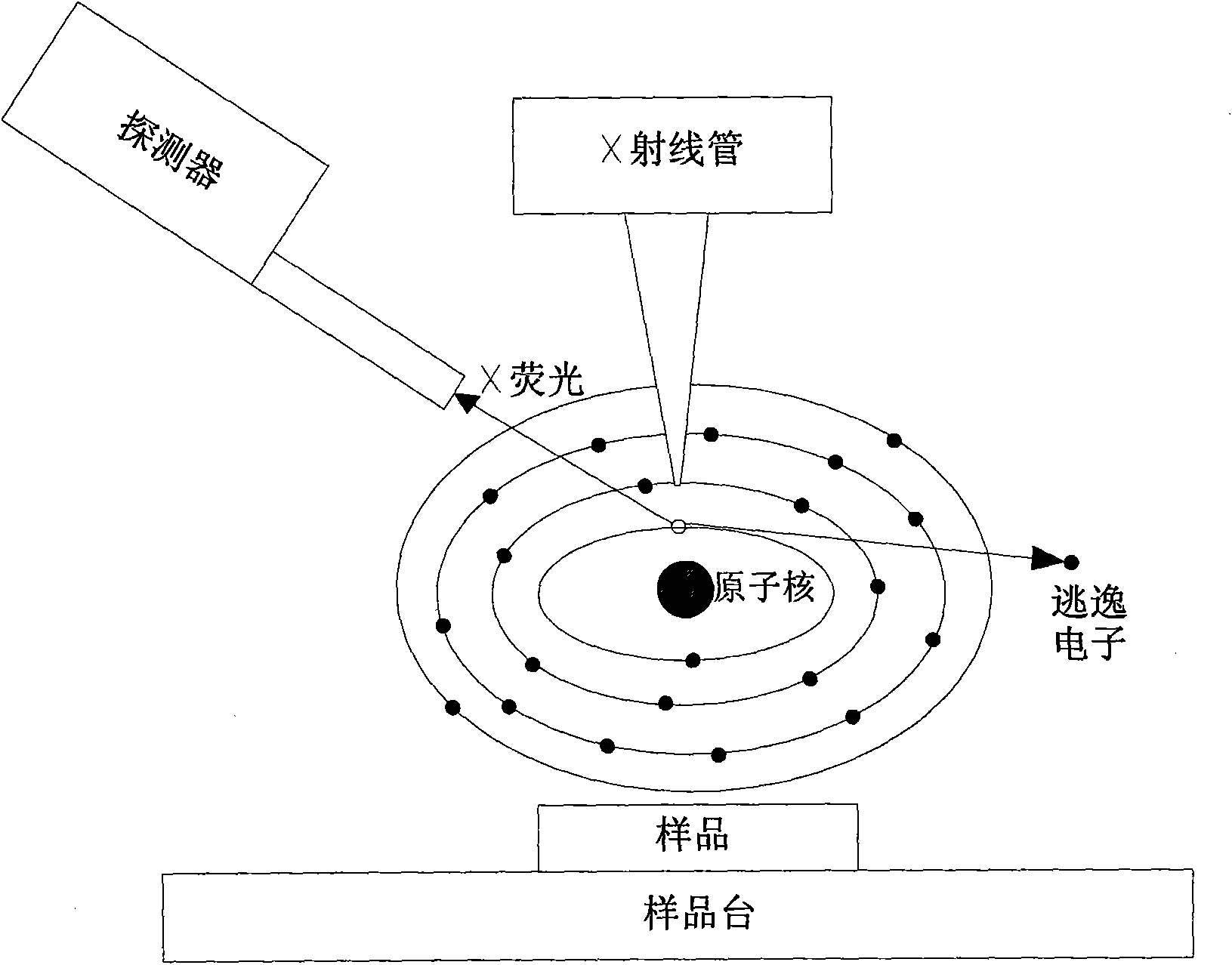

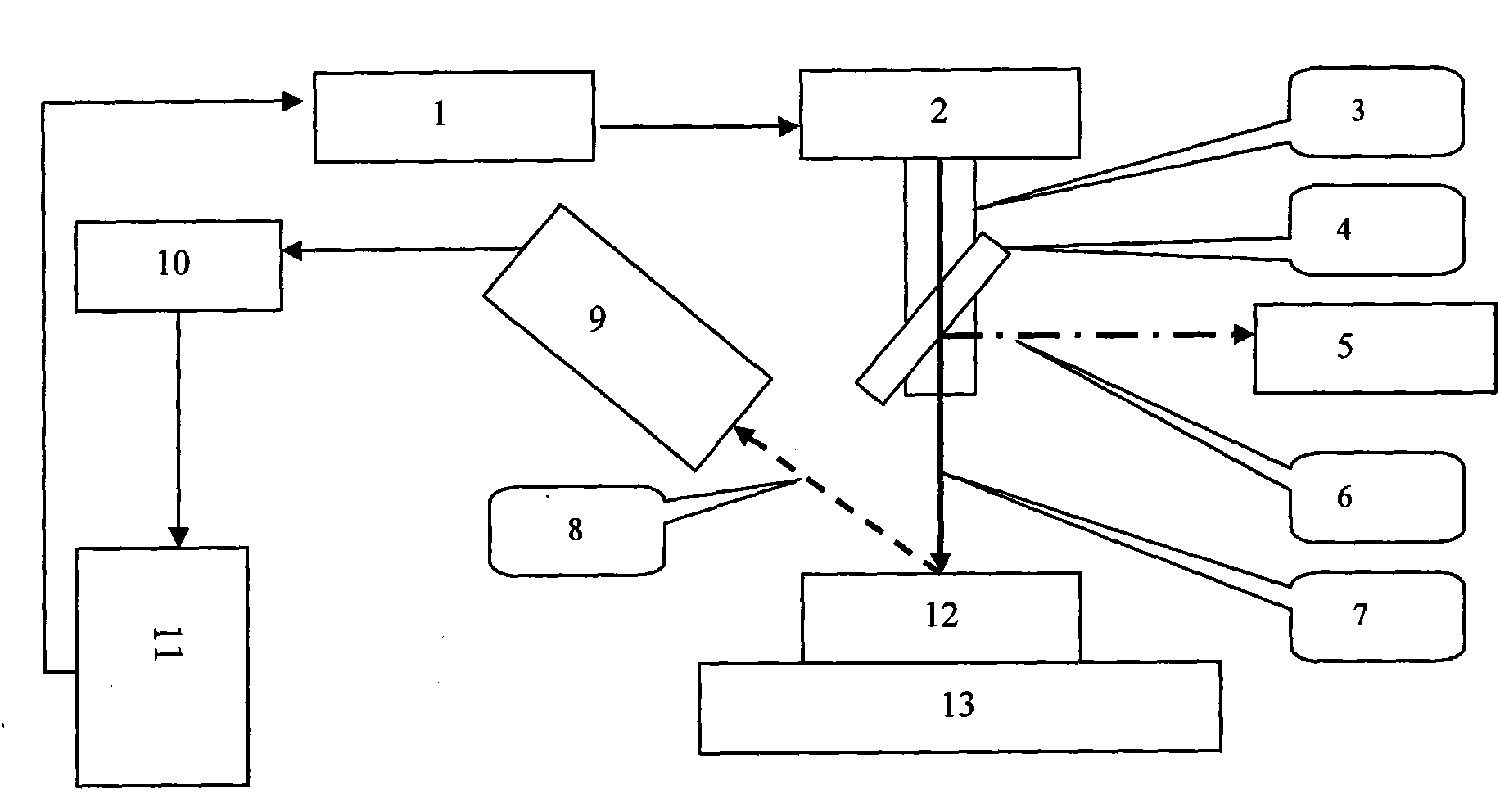

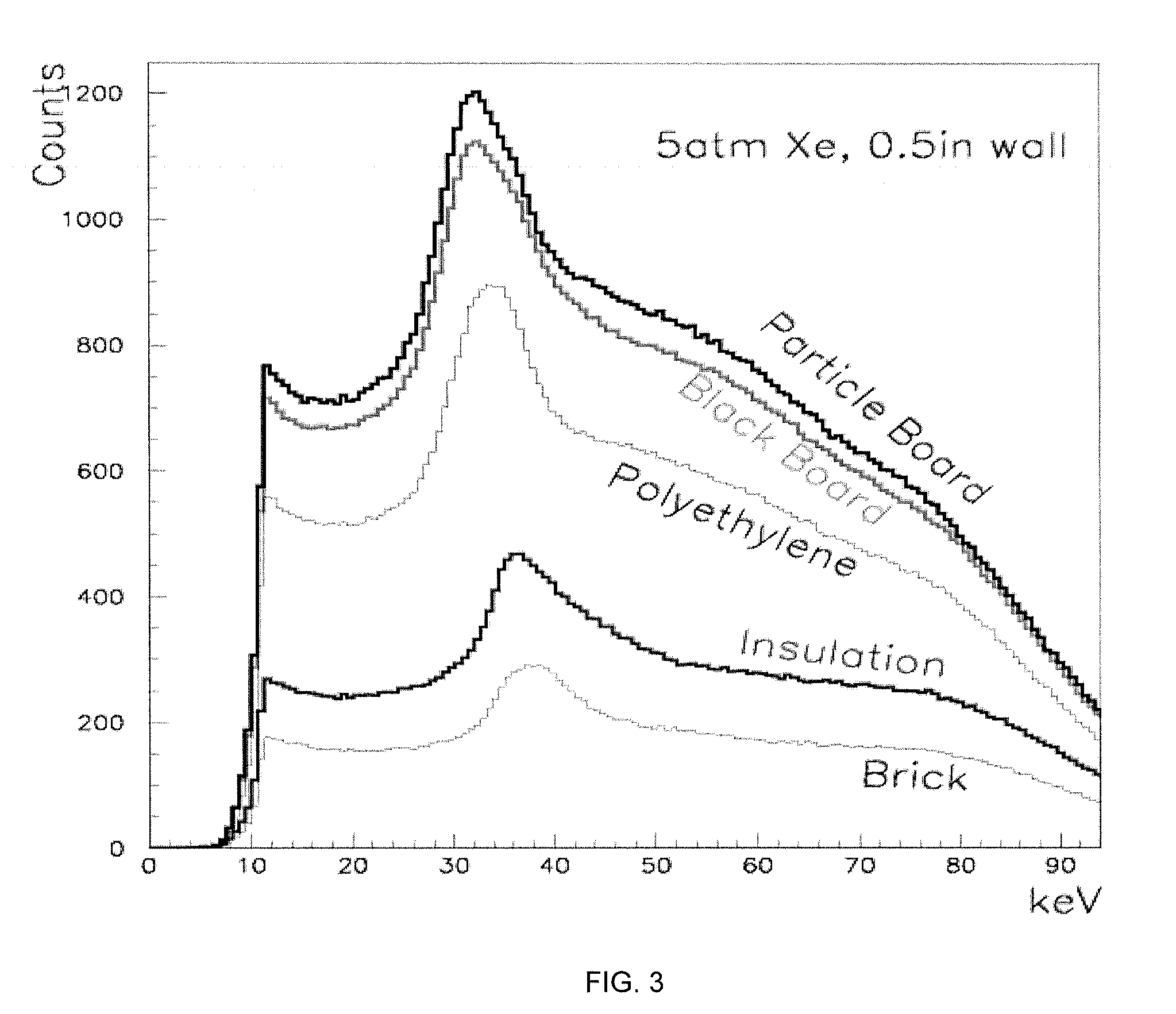

The invention provides a device for measuring a coating by using an X-ray fluorescence spectrometer. The device comprises a high voltage generator, an X-ray tube, a collimator, a lens, a camera, a probe, a multi-channel plate and a computer, wherein the high voltage generator is connected with the X-ray tube to provide high voltage for the X-ray tube; the X-ray tube is connected with the collimator; an electric signal is converted into an electric pulse by probing the X ray reflected by a sample with the probe; the electric pulse is amplified by an amplifier MCA; the amplified signal is transmitted to the multi-channel plate; and a communication signal is formed by the multi-channel plate and transmitted to the computer for processing. The method comprises the following steps of: (1) generating the high voltage; (2) mainly converting kinetic energy of electrons into primary radiation in the X-ray tube; (3) using the collimators with different sizes and shapes; (4) receiving the X fluorescence by a probe window; (5) using a proportional counter filled with xenon gas; (6) transmitting the signal of the amplifier into the computer; and (7) displaying data and the image of the sample on a display.

Owner:上海优特化工有限公司

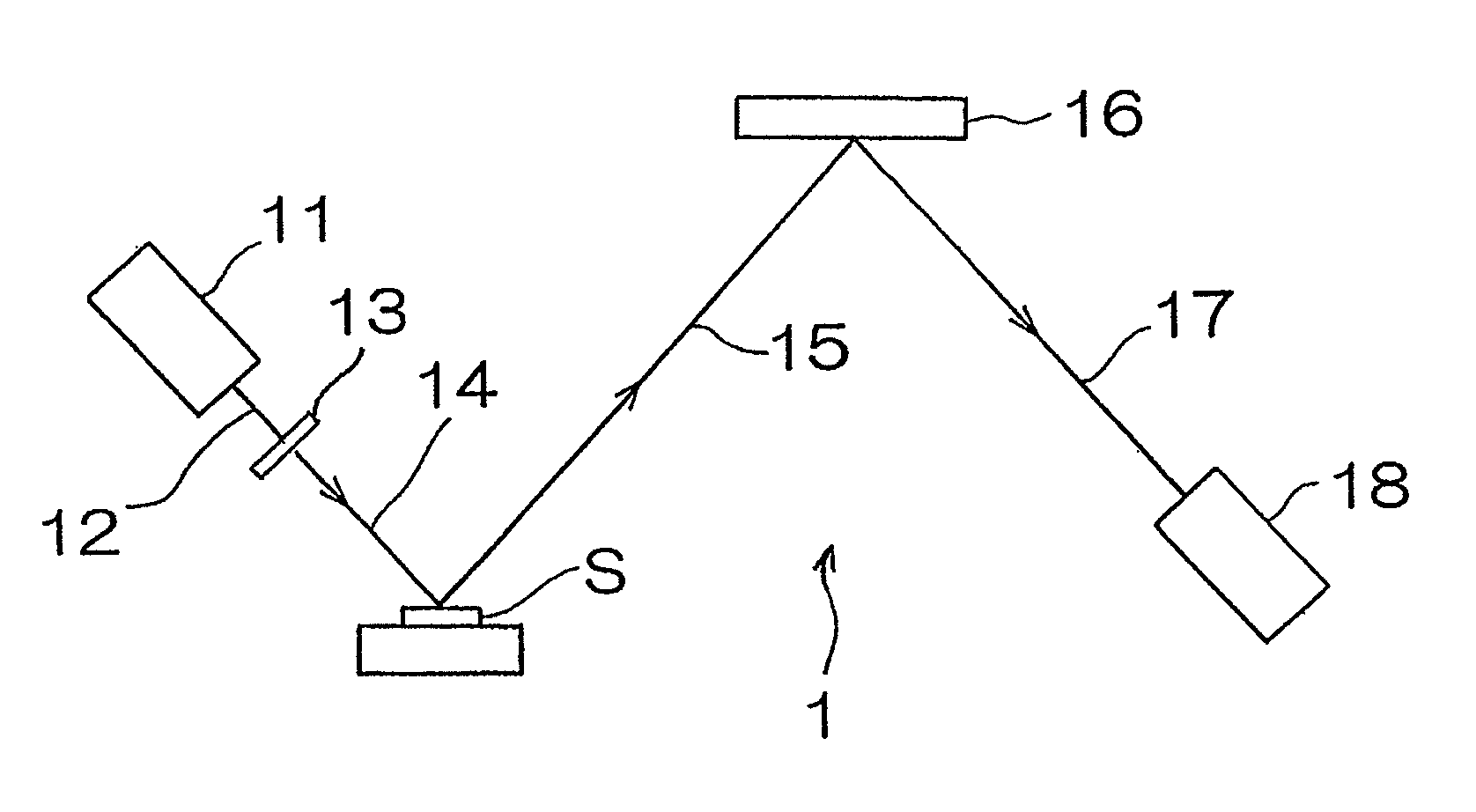

X-ray fluorescence spectrometer

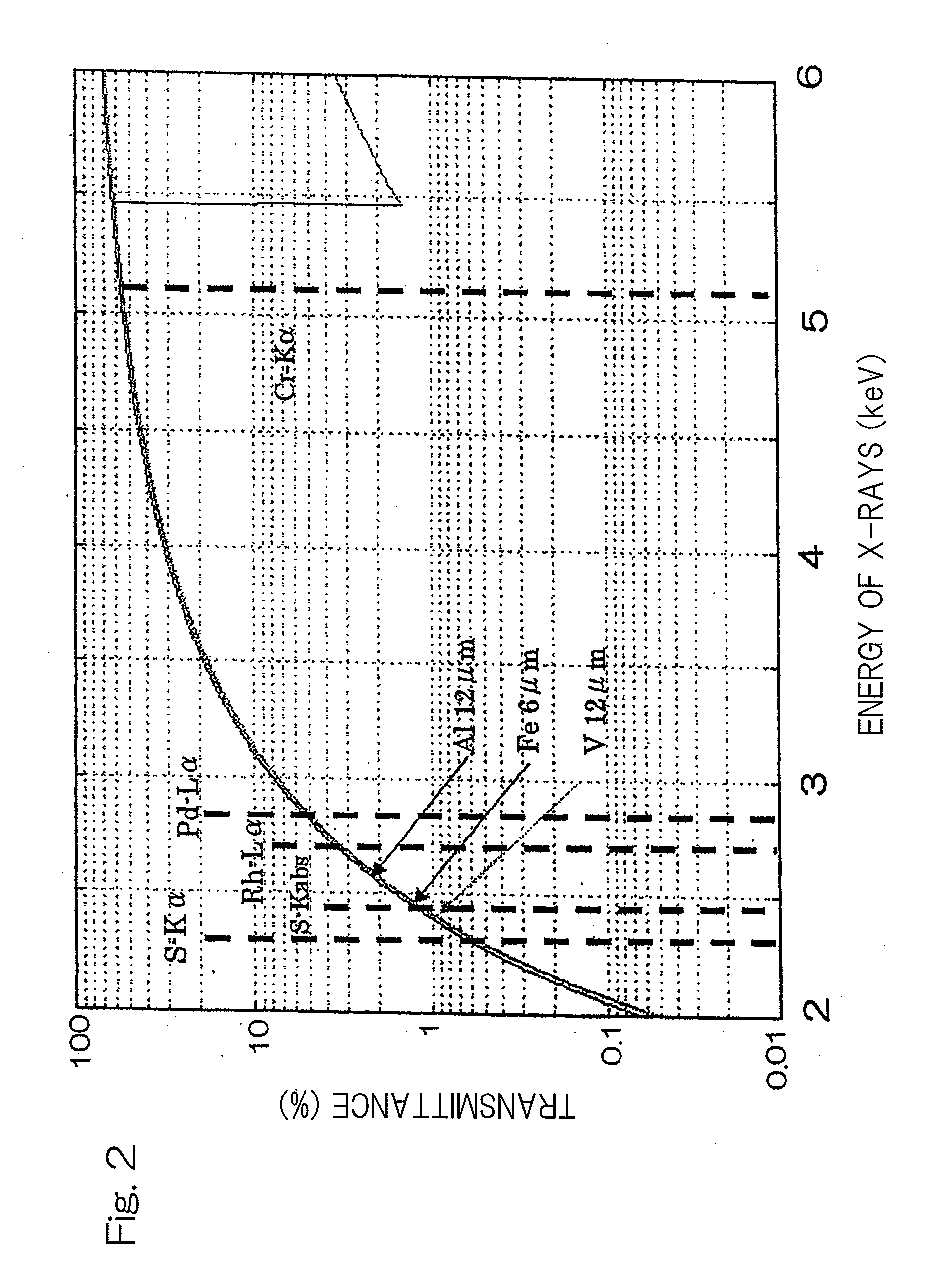

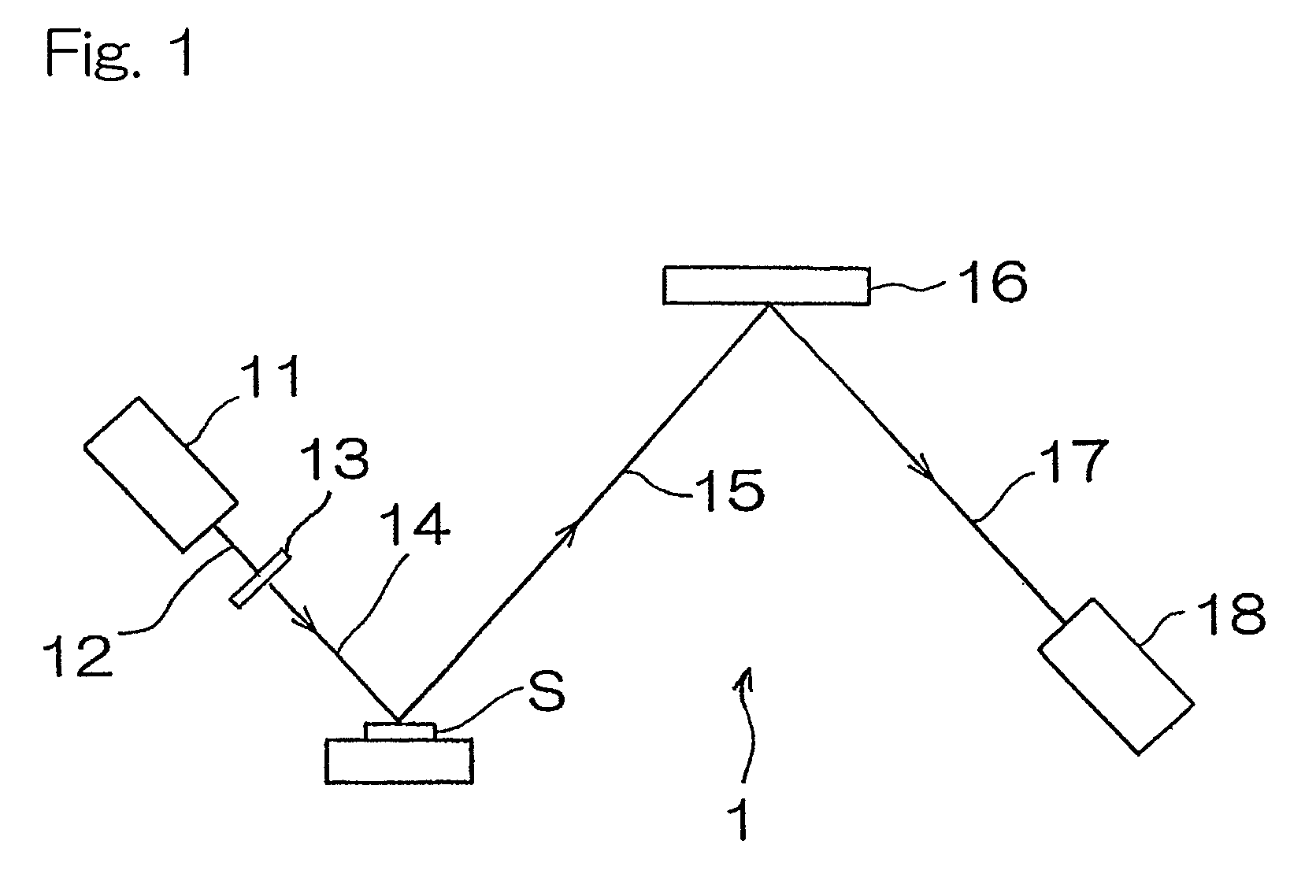

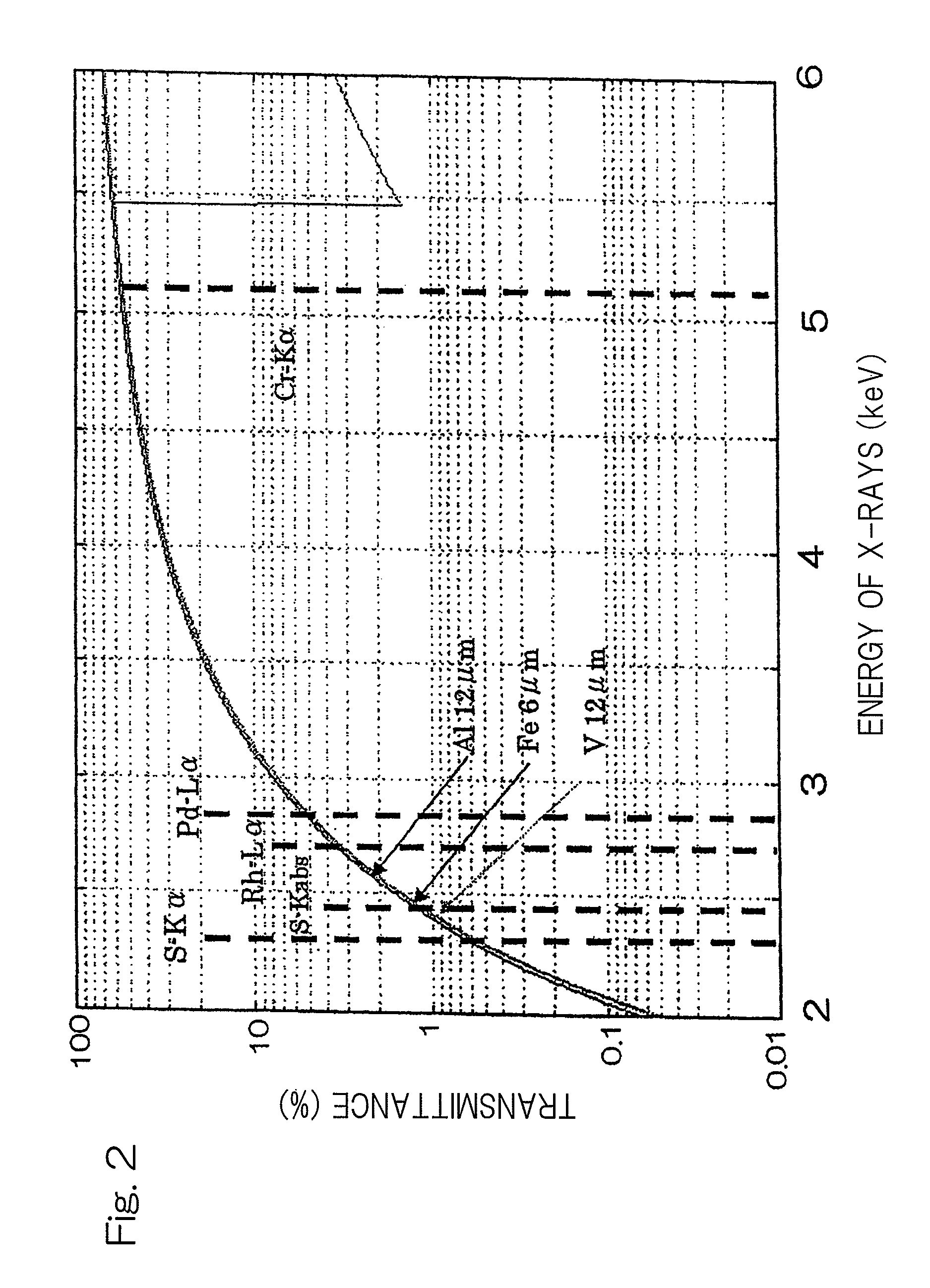

InactiveUS20090116613A1Low detection limitBackground intensity can be minimizedX-ray spectral distribution measurementMaterial analysis using wave/particle radiationX-ray filterX-ray

An X-ray fluorescence spectrometer for measuring the concentration of sulfur contained in a sample (S), by irradiating the sample (S) with primary X-rays from an X-ray tube (11), monochromating fluorescent X-rays emitted from the sample (S) with a spectroscopic device, and detecting monochromated fluorescent X-rays with an X-ray detector. The spectrometer includes the X-ray tube (11) having a target with an element including chromium, an X-ray filter (13) disposed on a path of travel of X-rays between the X-ray tube (11) and the sample (S) and having a predetermined transmittance for Cr—Kα line from the X-ray tube (11) and made of a material which is an element of which absorption edges do not exist between energies of S—Kα line and Cr—Kα line, and a proportional counter (18) having a detector gas containing a neon gas or a helium gas.

Owner:RIGAKU CORP

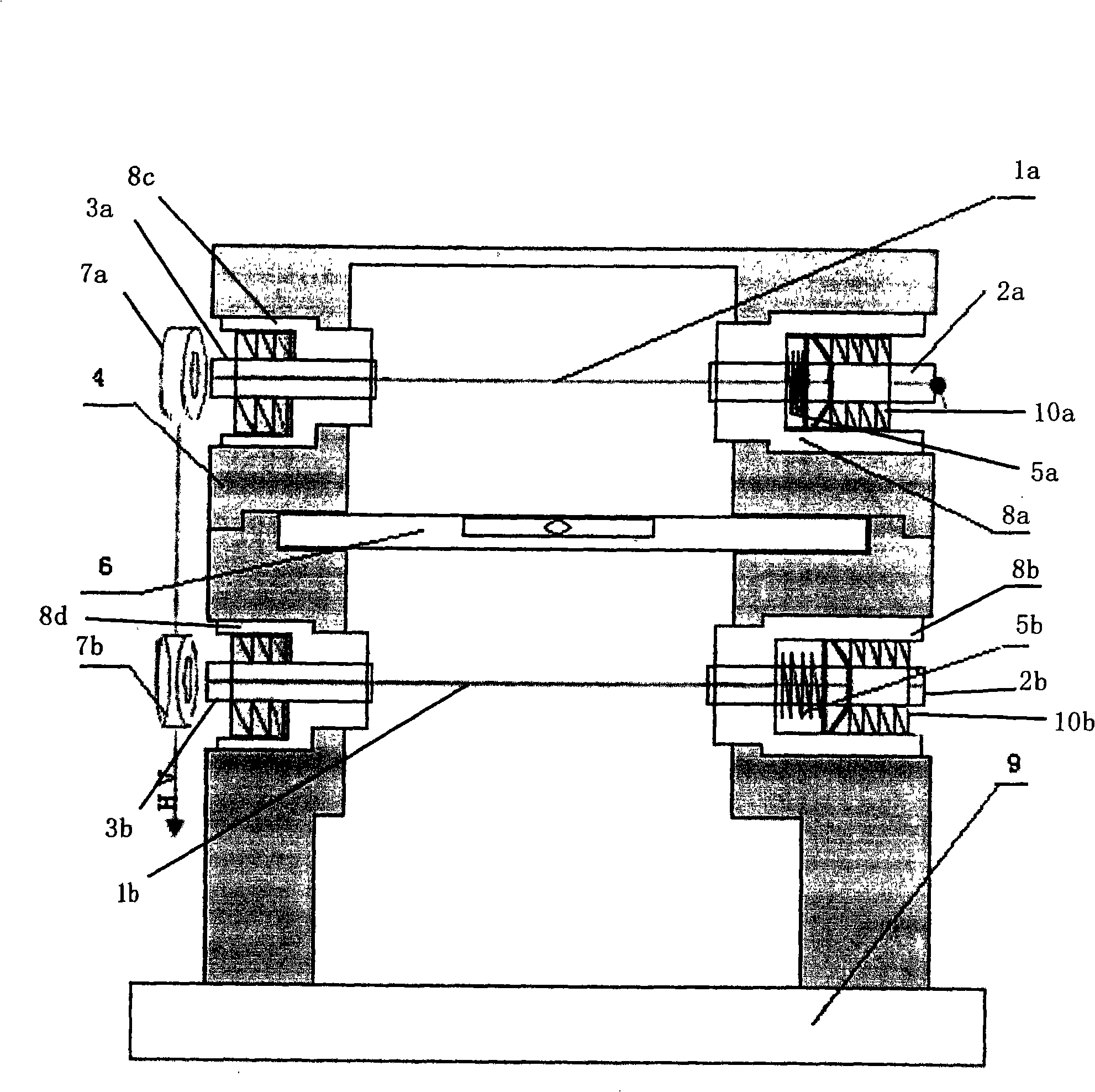

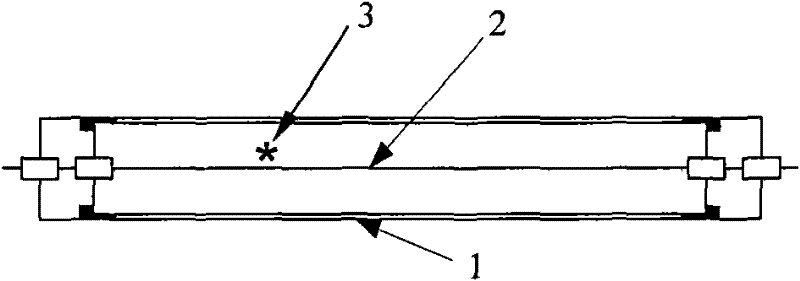

Minitype 4 pi beta proportional counter

InactiveCN101256240AUniform electric field distributionEasy to connect repeatedlyRadiation intensity measurementCounting rateSignal-to-noise ratio

The invention discloses a minitype 4 pi beta proportional counter, mainly composed of columnar and symmetry up and down 2 pi proportional counters, wherein the gilt tungsten wire in the counter is used as anode and the two ends of the gilt tungsten wire respectively pass through copper tube and are welded with the copper tube, and the shell of the counter is used as cathode and the copper tube passes through the shell and insulates with the shell by olytetrafluoroethylene sleeve. A base is connected with the bottom of the device by bolt joint and a spring is set between the copper tube and shell. A sample torr is set between the two 2 pi proportional counters. The invention provides a minitype 4 pi beta proportional counter with even electric field distribution, high signal-noise ratio, narrow pulse width, suitable for measuring at high counting rate.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

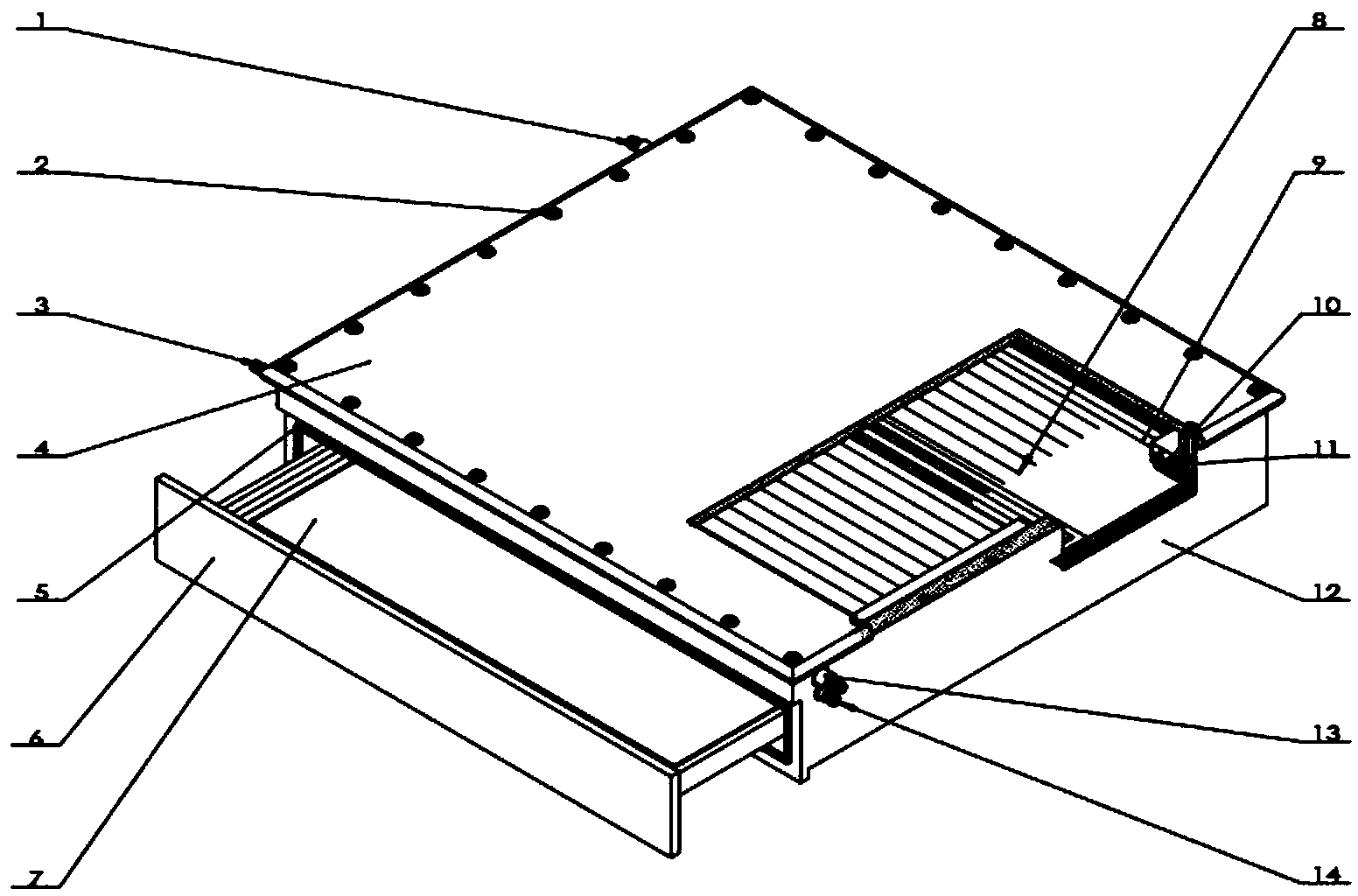

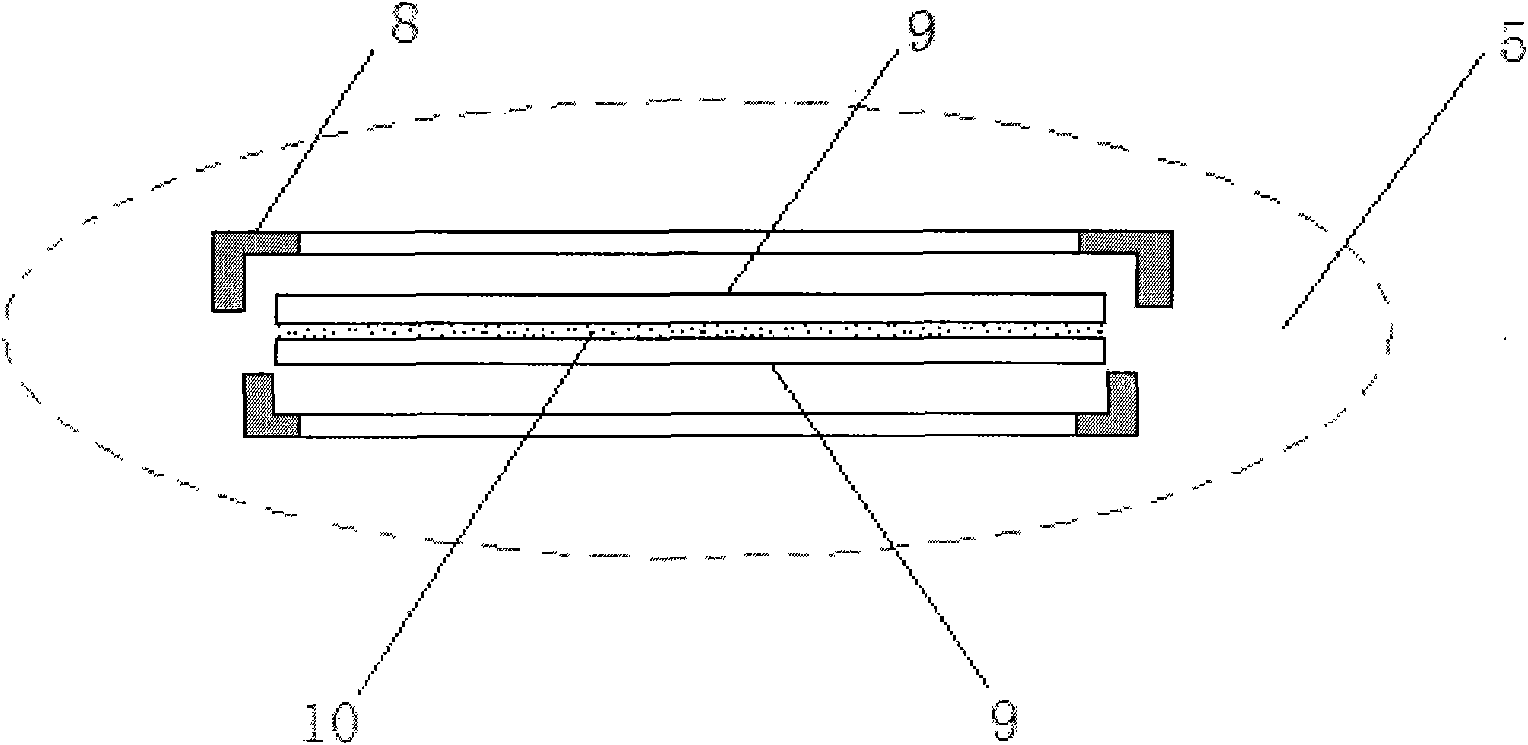

Two-pi multi-wire gas-flow proportional counter

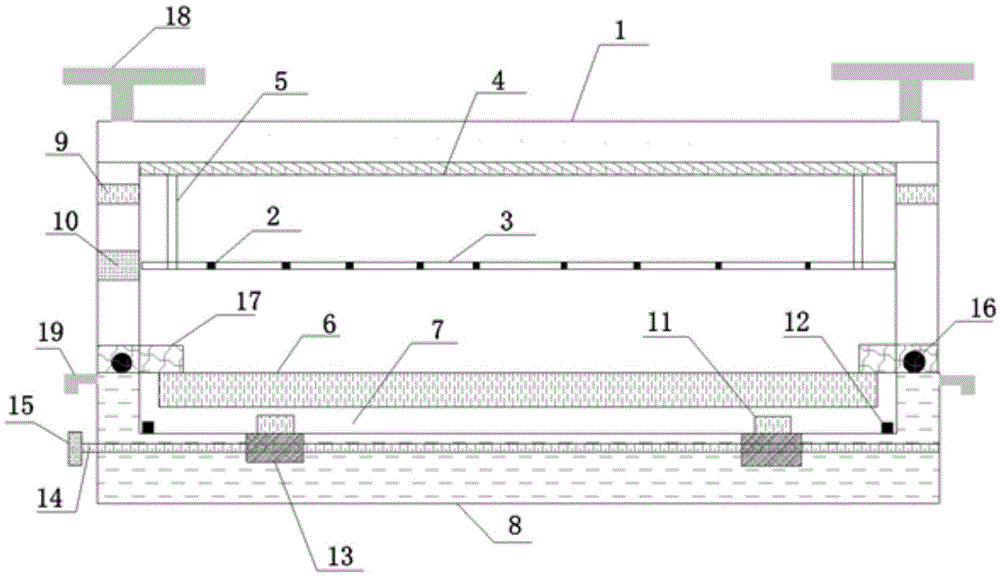

ActiveCN103926615AHigh parallelismPing characteristics are goodRadiation intensity measurementEngineeringTungsten

The invention belongs to the technical field of dosage measurement, and discloses a two-pi multi-wire gas-flow proportional counter. The counter is of a plate-type drawer structure and mainly comprises a counter shell, anode wires, an anode wire frame, insulation frameworks and a source drawer, wherein the counter shell is a square frame composed of an upper cover plate and shell side walls, the source drawer goes into and out of the counter shell through a guide rail, each shell side wall is provided with an air inlet and an air outlet, the anode wire frame is a square frame and is located between the upper insulation framework and the lower insulation framework, the lower insulation framework is fixed to the shell side walls, the upper insulation framework is located below the upper cover plate, the edges of the upper portions of the shell side walls are provided with a sealing ring, the upper cover plate is fixedly connected with the shell side walls, the anode wires are fixed to the anode wire frame, and the anode wires are gold-plated tungsten wires distributed at equal intervals in parallel. The counter has the advantages that the effective detection area is as large as 1000 square centimeters, the anode wires are distributed in parallel, gas disturbance is little, and electric fields are uniformly distributed.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

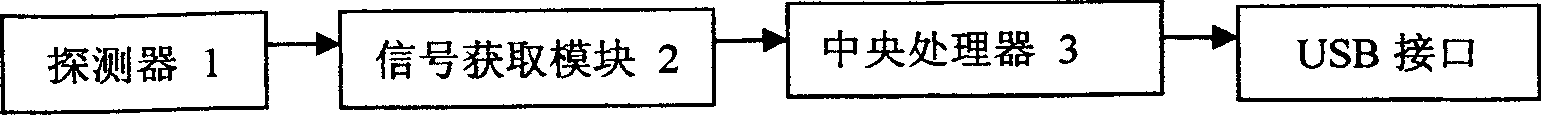

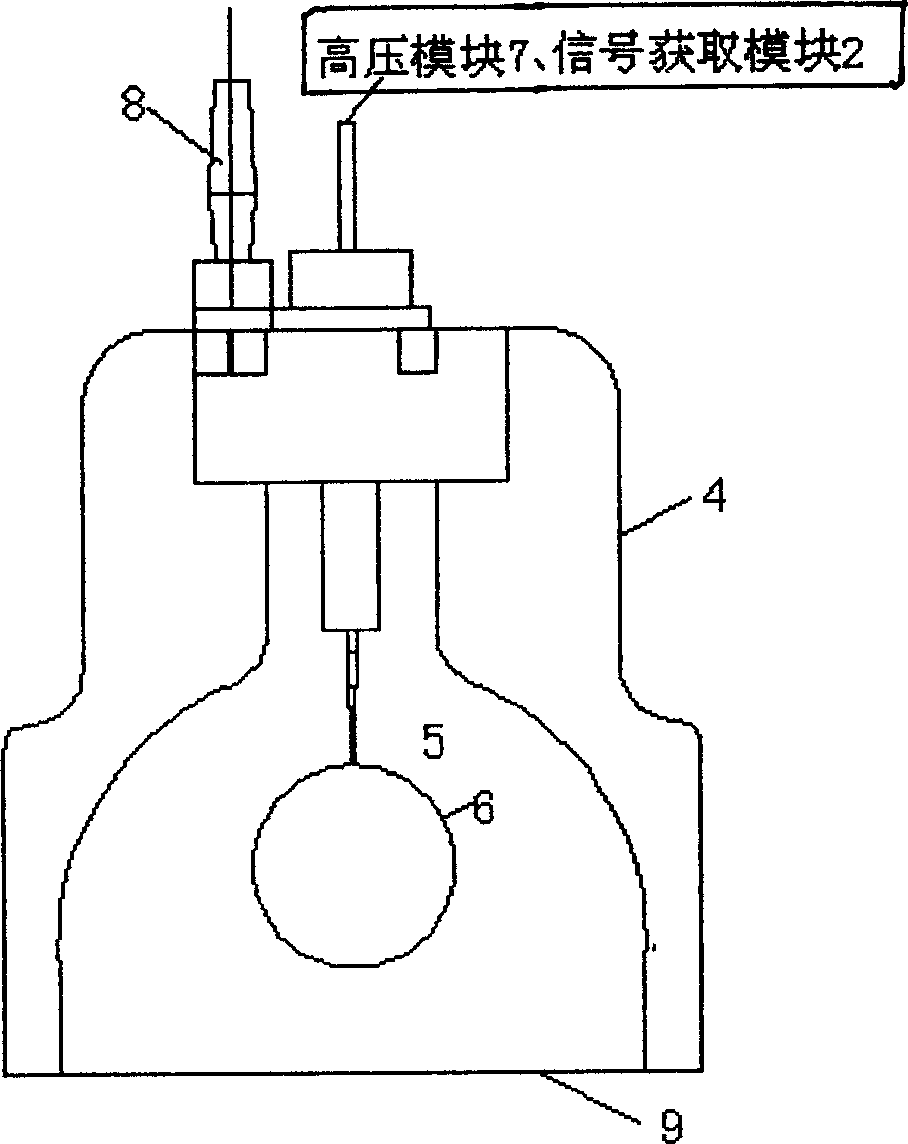

Tritium surface pollution monitor

InactiveCN1900742AReduce manufacturing costHigh detection sensitivityRadiation intensity measurementEngineeringMethane gas

The invention is related to instrument for monitoring pollution on surface of tritium in order to solve issues of high cost of device, low efficiency of detection, and poor anti-interference. The invention includes detector, module of signal acquisition, and CPU. Detector is proportional counter in flowing gas type. The counter is composed of cathode of metal covering, as well as anode in wire or piece in inner cavity. Being connected to the output of high voltage module, anode through signal line is connected to the input of the module of signal acquisition. There are gas inlet orifice and gas outlet orifice in the inner cavity. In time of operation, methane gas enters into the inner cavity through the gas inlet orifice, and outflows through the gas outlet orifice continually.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY +2

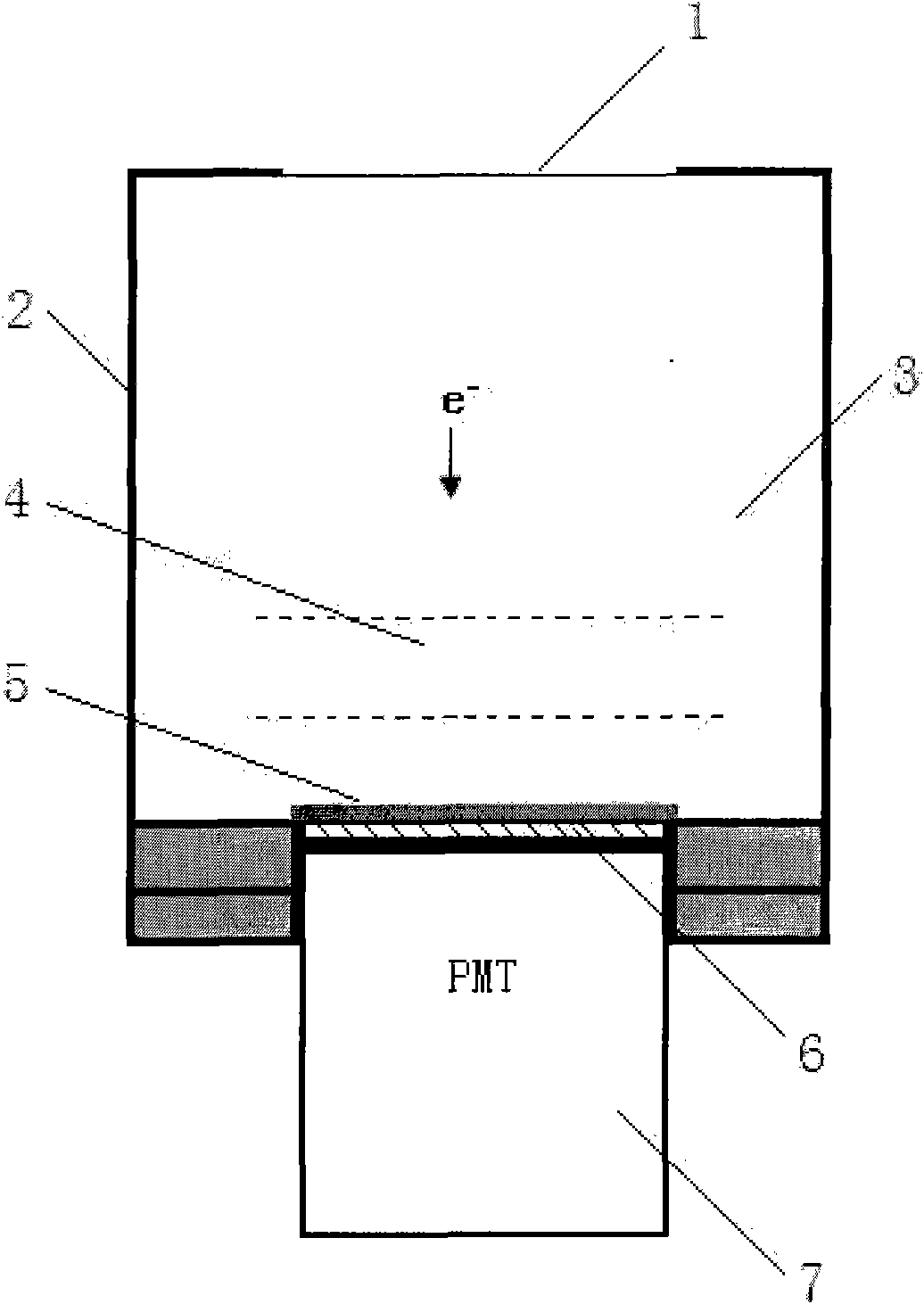

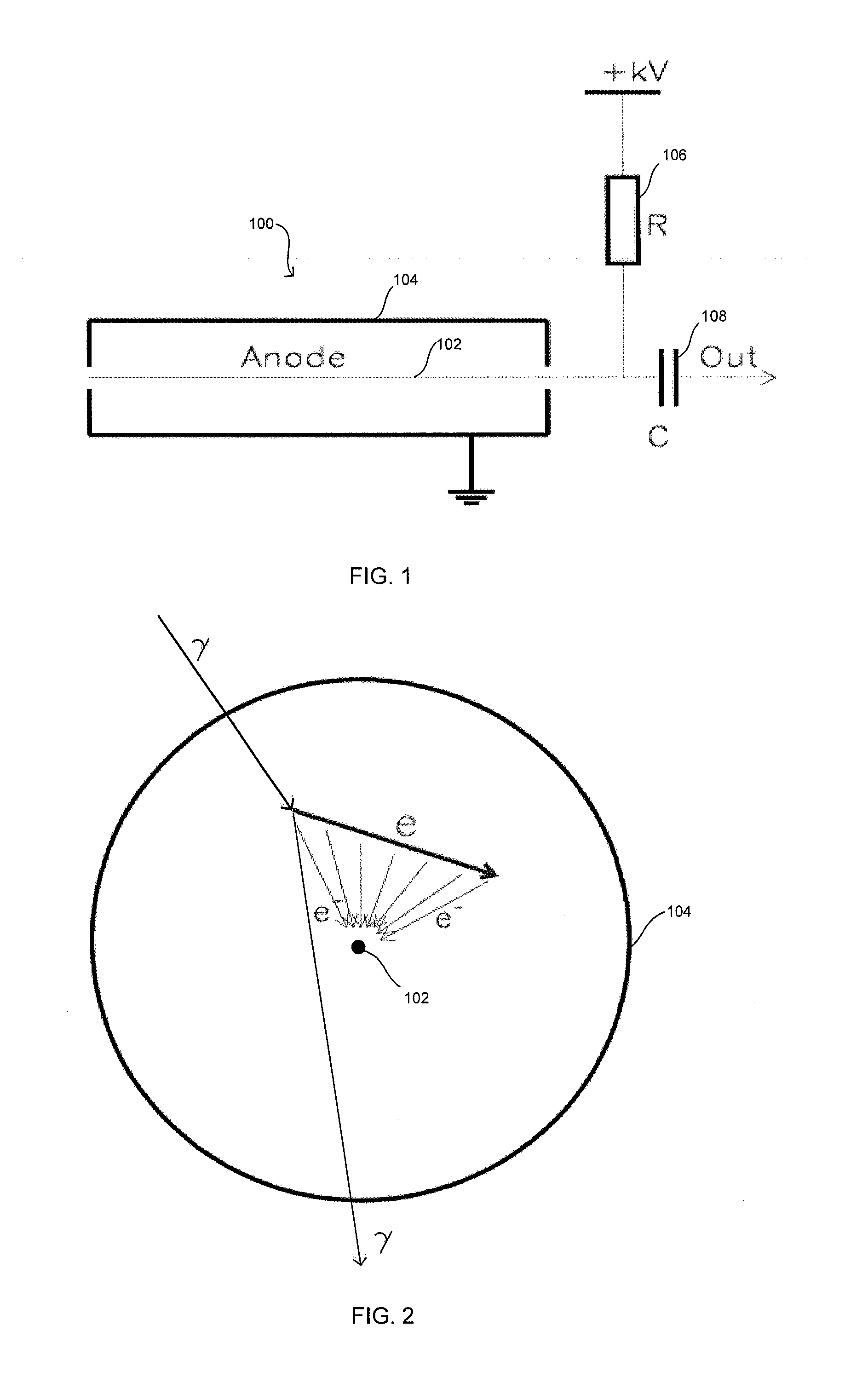

Gas scintillation proportional counter

ActiveCN101581788ALow costImproved energy resolutionX/gamma/cosmic radiation measurmentX-rayGamma ray

The invention provides a gas scintillation proportional counter, consisting of a gas container and a photomultiplier tube, wherein the gas container is filled with working gas; an entrance window and an exit window are respectively arranged above and under the gas container which is internally provided with an electric field; Gamma ray or X ray enters the gas container after penetrating the entrance window, and has a photoelectric effect with the working gas in the gas container so as to generate photoelectrons; under the action of the electric field, the electrons are accelerated by the electric field, then excite gas atoms to emit vacuum ultraviolet photons which are emitted from the exit window and detected by the photomultiplier tube, and the upper part of the exit window is a wavelength conversion structure. The gas scintillation proportional counter can meet the need of measurement of internal radiation living bodies after the body intakes low-energy nuclide, and can detect the returned laser of the working gas by only needing to use the common photomultiplier tube, thus greatly reducing the cost of the gas scintillation proportional counter.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

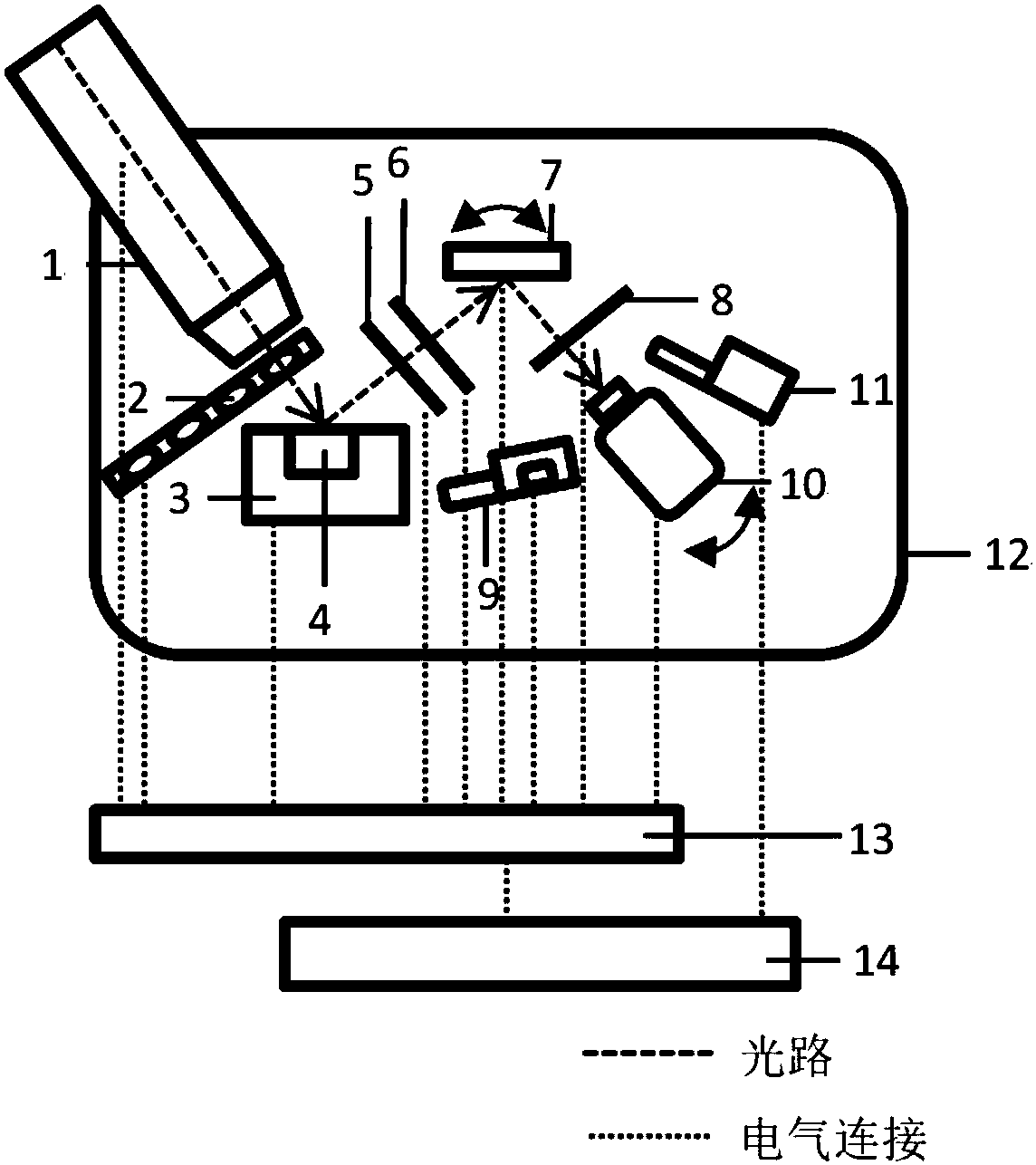

Wave spectrum and energy spectrum composite type X-ray fluorescence spectrophotometer

PendingCN108508051ALarge application spaceImprove reliabilityMaterial analysis using wave/particle radiationFace scanningElement analysis

The invention provides a wave spectrum and energy spectrum composite type X-ray fluorescence spectrophotometer. The wave spectrum and energy spectrum composite type X-ray fluorescence spectrophotometer comprises an X-ray source, a light filter switching mechanism, a sample moving platform, a sample cup, a diaphragm switching mechanism, a primary collimator switching mechanism, a dispersive crystalswitching mechanism, a secondary collimator switching mechanism, a gasflow type proportional counter, a scintillation counter, an SDD detector, a main control panel and a PC machine. The wave spectrum and energy spectrum composite type X-ray fluorescence spectrophotometer has the following advantages: detection or point / face scanning can be rapidly completed by using an energy spectrum function when the sample is subjected to integrated component analysis and distribution analysis, and the whole body or certain area of the sample can be subjected to element analysis and distribution analysisby a wave spectrum function, so that organic combination of the wave spectrum and energy wave spectrum functions is realized, the two functions can be applied to integrated element component analysisand distribution analysis of the sample, the characteristics of high resolution, rapidness, flexibility and combinability are achieved, the reliability of the analysis result can be improved and the detection efficiency can be improved obviously.

Owner:NAT RESERACH CENT OF GEOANALYSIS +1

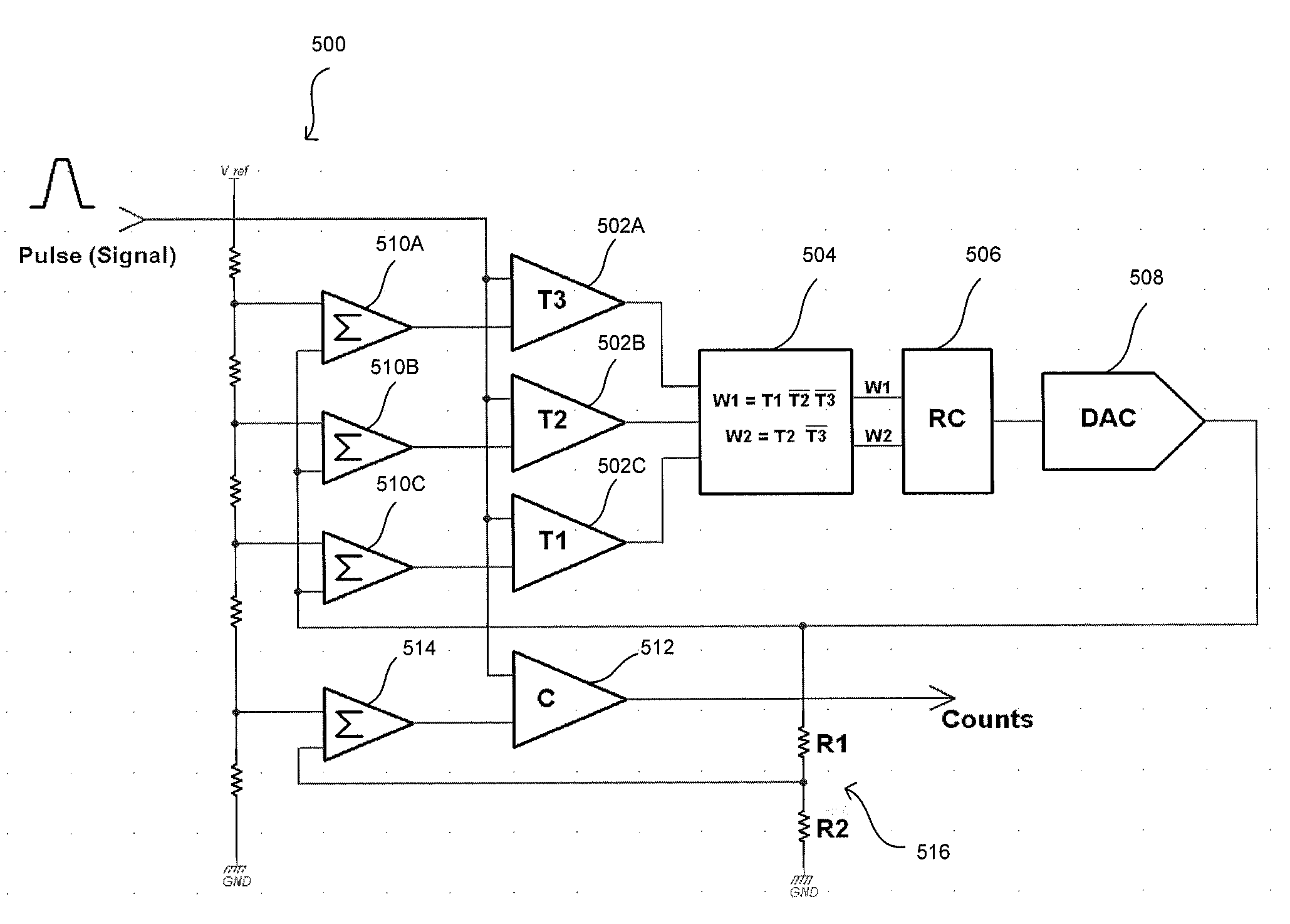

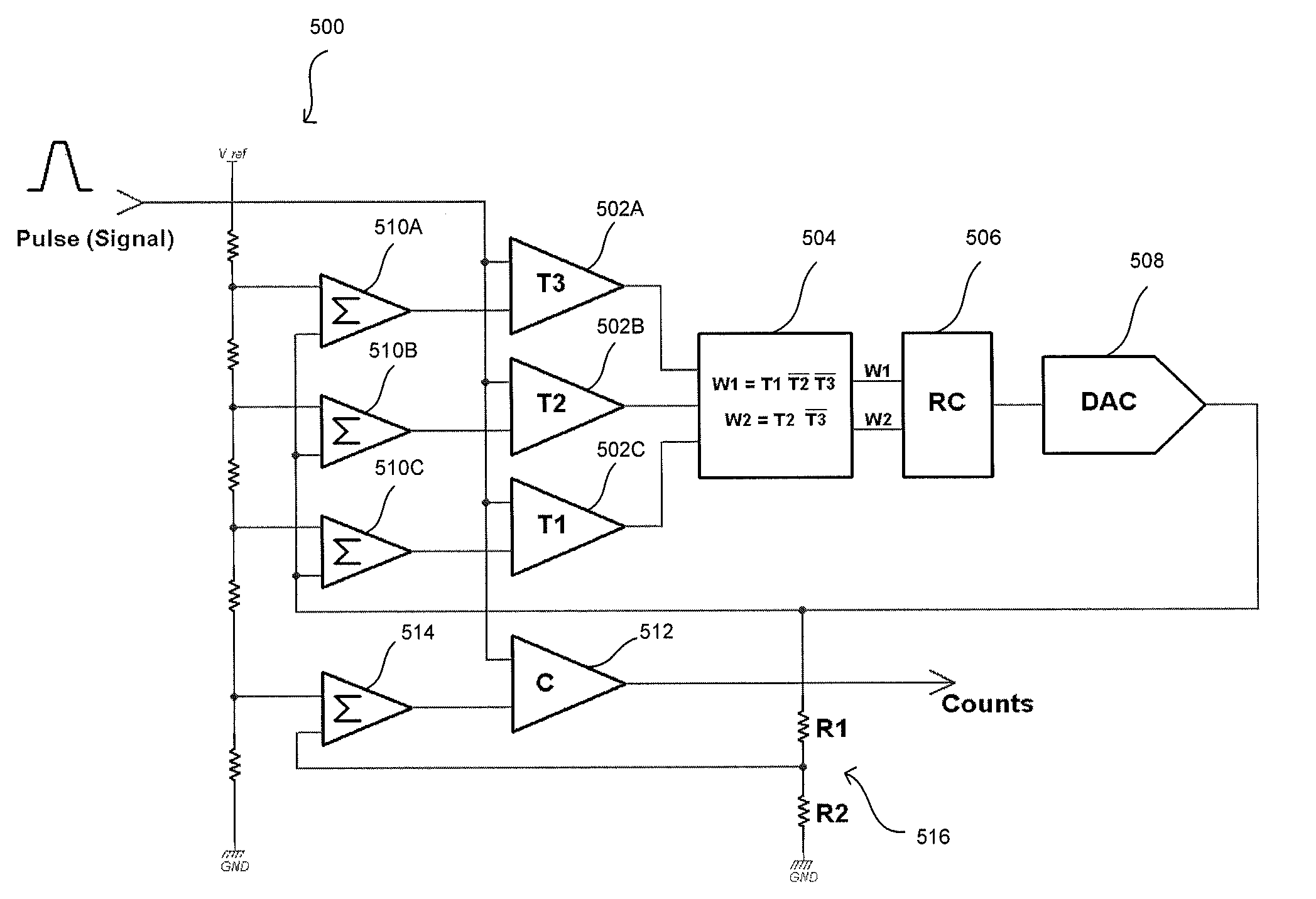

Method and apparatus to monitor gain of a proportional counter

A method and apparatus in accordance with the present disclosure relate to monitoring gain of a proportional counter. The method includes generating a pulse height spectrum of the proportional counter, defining a first window and a second window within the pulse height spectrum, counting electrical pulses outputted by the proportional counter within the first window of the pulse height spectrum, thereby defining a first window count, counting electrical pulses outputted by the proportional counter within the second window of the pulse height spectrum, thereby defining a second window count, and determining a difference between the first window count and the second window count.

Owner:THERMO FISHER SCIENTIFIC INC

Method and device for simulating multisphere neutron spectrometer by utilizing position sensitive proportional counter tube

InactiveCN102455433AEasy to measure structureGood energy responseNeutron radiation measurementNeutron radiationSpectrometer

Owner:CHINA INST FOR RADIATION PROTECTION

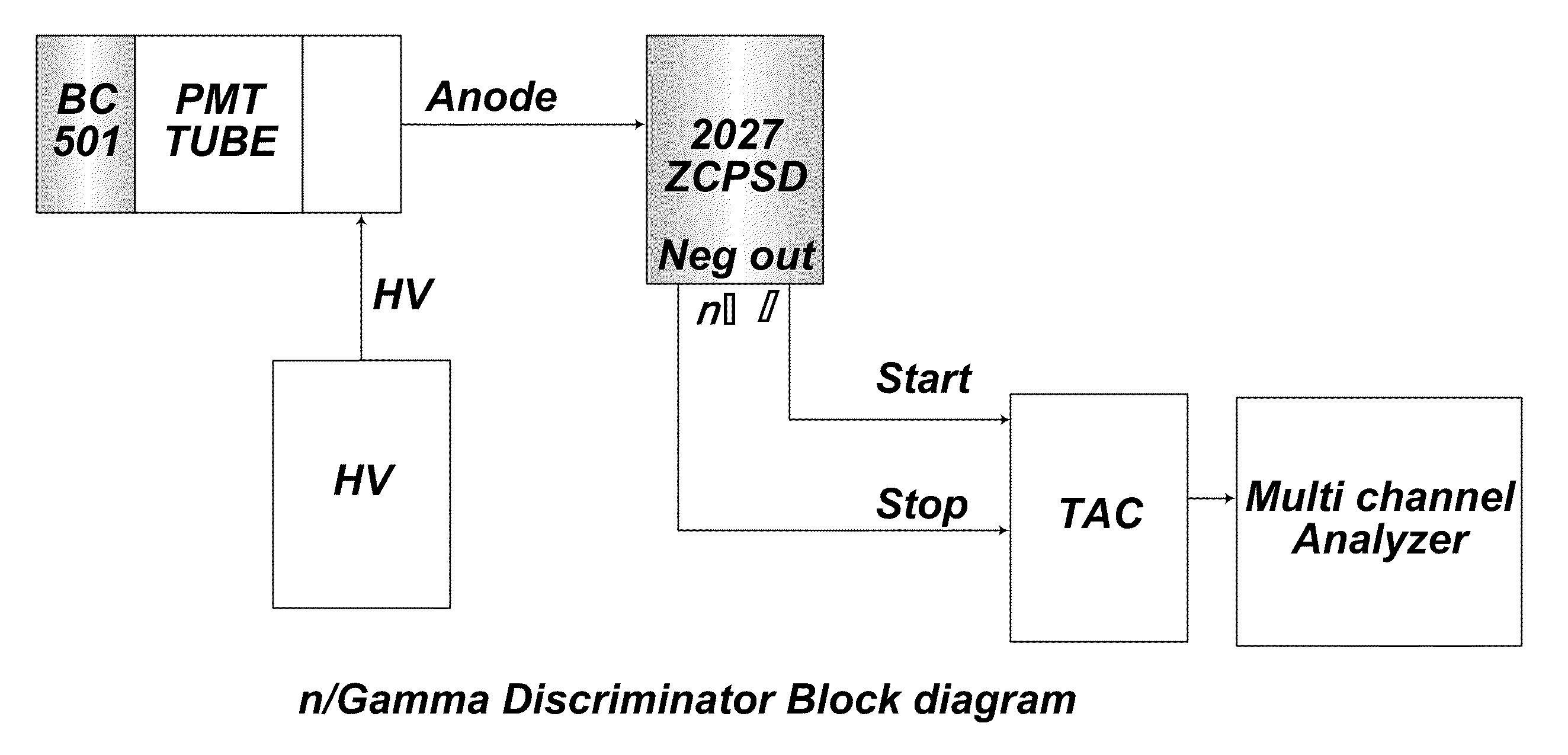

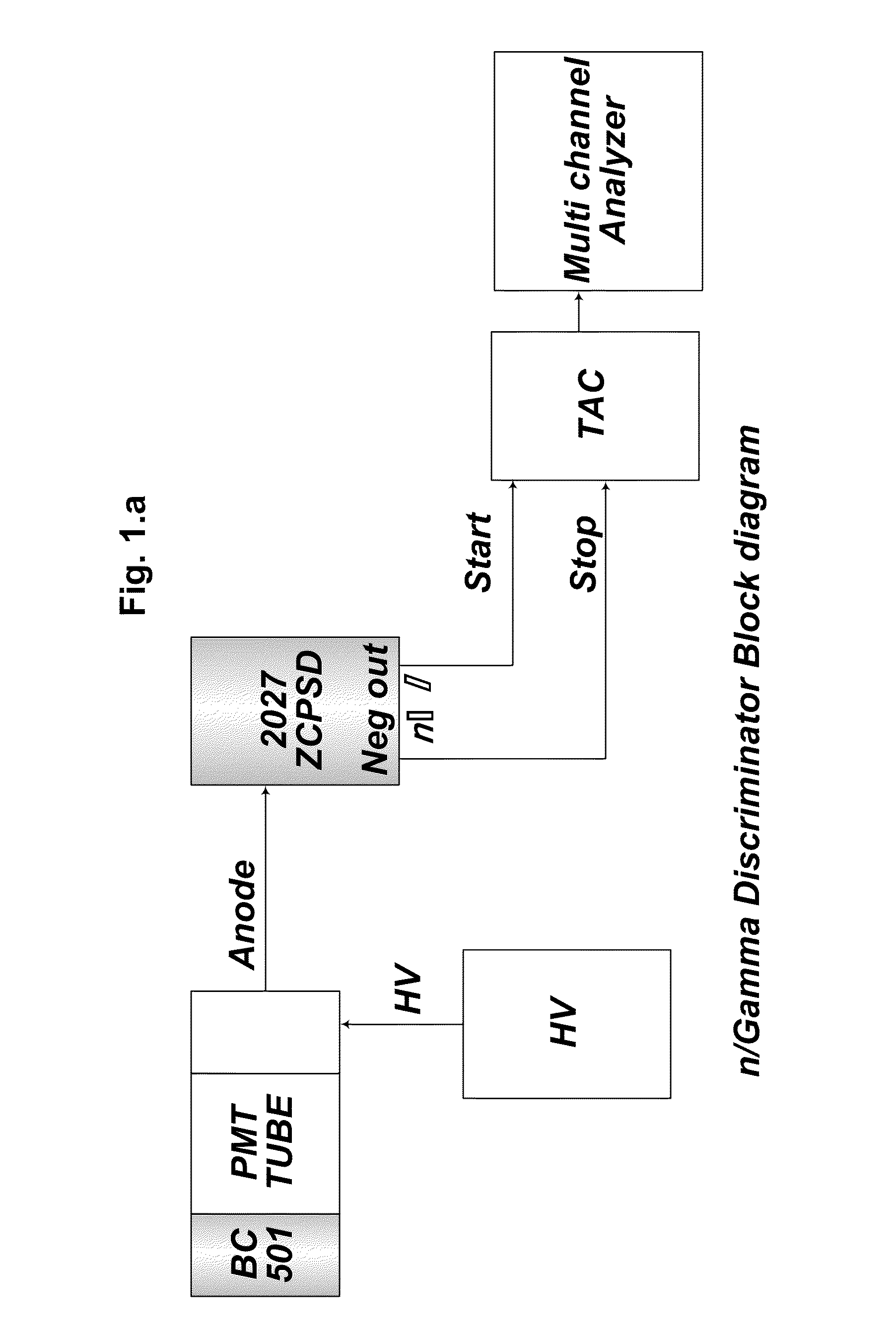

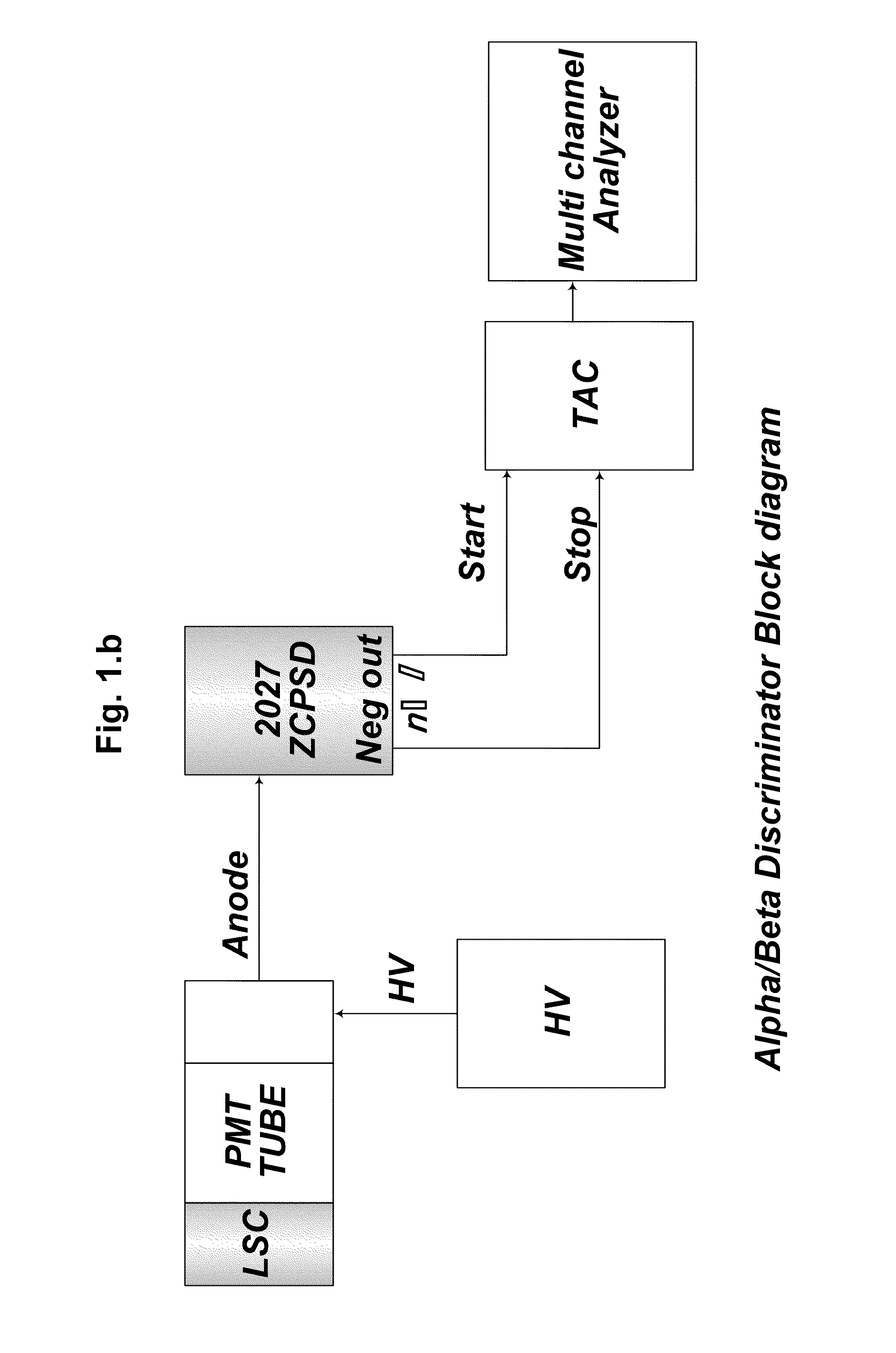

Method and system for discrimination pulse shape

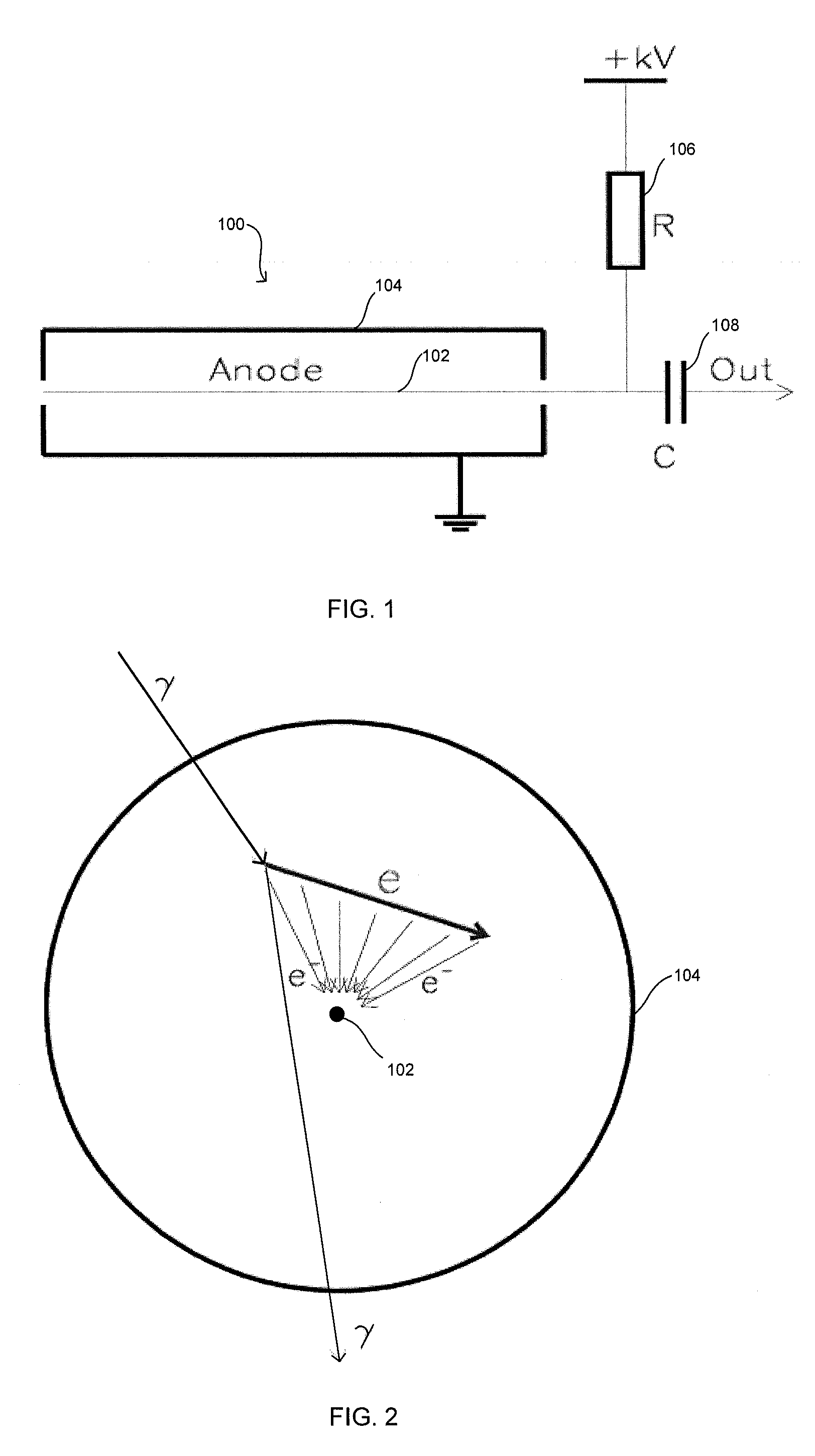

InactiveUS20100308231A1Large dynamic rangeQuickly checking system capabilityMeasurement with scintillation detectorsMaterial analysis by optical meansScintillation counterElectron

This ZCPSD Module can be used to separate neutron and gamma particles, alphas and protons, electrons and alphas etc depending on the detector used. ZCPSD provides optimum pulse shape separation for liquid scintillation counters. However the applications are not limited to n / γ separation. The ZCPSD can also be used for particle separation with inorganic scintillators, phoswitches, thick SBdetectors and proportional counters. The dc coupling allows high statistical count rate without affecting resolution, a major problem of conventional designs. The Single width NIM conforming to International Standards is easy to use, since only the anode signal is required from PM tubes. The ZCPSD can be used to generate identification spectra with a TAC and MCA or an identification signal for one species of particle.

Owner:SHARGHI IDO AMIN +1

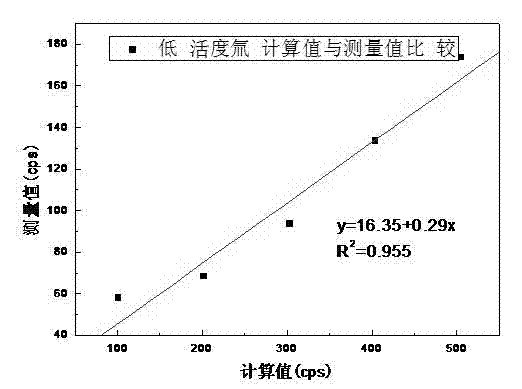

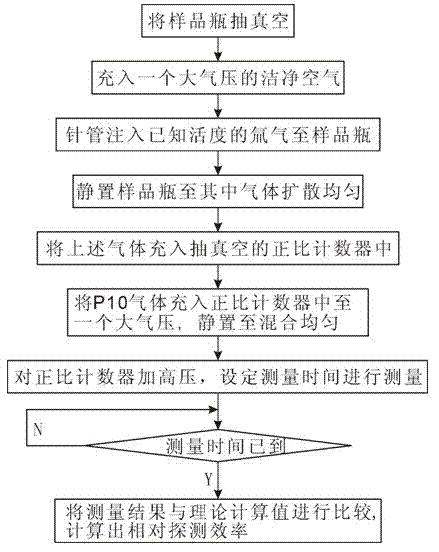

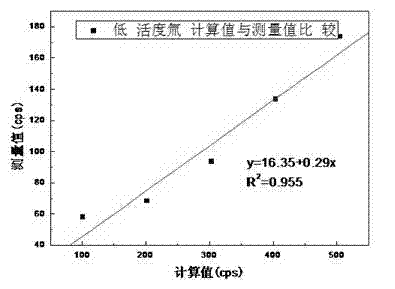

Gas state tritium activity measuring method

InactiveCN103091696AQuick measurementAccurate measurementX/gamma/cosmic radiation measurmentMeasurement deviceUnknown activity

The invention discloses a gas state tritium activity measuring method with a low activity. The method is applied to a gas state tritium activity measuring device, and comprises collection of gas state tritium samples, calibration of measuring results when no standard gas state tritium samples exist, and proceeding of activity measurement for gas state tritium samples with unknown activities by means of using of calibration results. As for tritium samples with high activities, the tritium samples are diluted through choosing and using of buffer bottles in different sizes. After measurement is finished, different methods are adopted to clean a proportional counter according to the measured activities, and memory effect of residual gas state tritium for the proportional counter is reduced to the greatest extent. The gas state tritium activity measuring method can effectively use the tritium samples with the known activities to calibrate, achieves effective measurement of the tritium samples with different activities to obtain accurate activity values, and improves accuracy of the low background gas state tritium activity measuring method.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

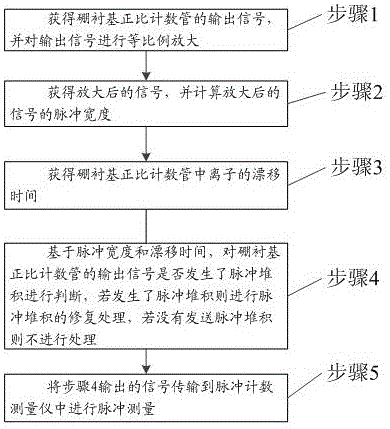

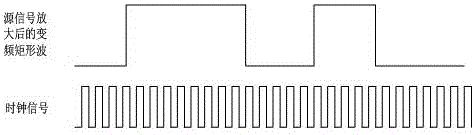

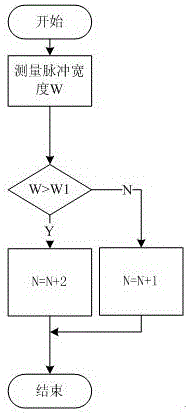

Pulse measurement method

ActiveCN106405616ARaise the upper limit of the measurementUpper limit level increasedRadiation intensity measurementProportional controlMeasuring instrument

The invention discloses a pulse measurement method. The method includes the following steps that: step 1, the output signals of a boron-lined proportional counter tube are obtained, and equal-proportion amplification is performed on the output signals; step 2, amplified signals are obtained, and the pulse width of the amplified signals is calculated; step 3, the drift time of icons in the boron-lined proportional counter tube is obtained; step 4, whether pulse stacking occurs on the output signals of the boron-lined proportional counter tube is judged based on the pulse width and the drift time, if pulse stacking occurs on the output signals of the boron-lined proportional counter tube, restoration processing for the pulse stacking is carried out, if pulse stacking does not occur on the output signals of the boron-lined proportional counter tube, no processing is performed; and sep 5, signals outputted from the step 4 are transmitted to a pulse counting measuring instrument for pulse measurement. With the pulse measurement method of the invention adopted, pulse measurement can be realized efficiently with low cost.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Neutron energy spectrometer

A neutron spectrometer is disclosed, which consists of a Helium-3 proportional counter connected by cable to signal and data processing circuits, and a series of moderator shells and moderator lids. The series of cylindrical moderator shells are designed to fit within one another, like Russian Matryoshka dolls, with the counter at the center. Small air gaps are introduced between the shells so that removal of one shell from another is facilitated. The counter is placed within the smallest cylindrical moderator shell, and then a circular lid matching the smallest shell is placed on the opening of the first shell to close the first shell. This first closed shell is then placed within a second shell, which shell is closed with its corresponding circular lid. The cable is routed through the series of shells. A method for using the invention is also disclosed, wherein the counter reading is taken from the fully-assembled neutron spectrometer. Then the outer cylindrical shell and circular lid pair is removed, and another measurement of the counter is recorded. This is continued until the last shell is removed, and a measurement is recorded using the bare counter.

Owner:3833364 CANADA OPERATING DETEC

Method and apparatus to monitor gain of a proportional counter including correcting the counting threshold of a pulse height spectrum

InactiveUS8937275B2Material analysis by optical meansPhotoelectric discharge tubesPulse heightPhysics

A method and apparatus in accordance with the present disclosure relate to monitoring gain of a proportional counter. The method includes generating a pulse height spectrum of the proportional counter, defining a first window and a second window within the pulse height spectrum, counting electrical pulses outputted by the proportional counter within the first window of the pulse height spectrum, thereby defining a first window count, counting electrical pulses outputted by the proportional counter within the second window of the pulse height spectrum, thereby defining a second window count, and determining a difference between the first window count and the second window count.

Owner:THERMO FISHER SCIENTIFIC INC

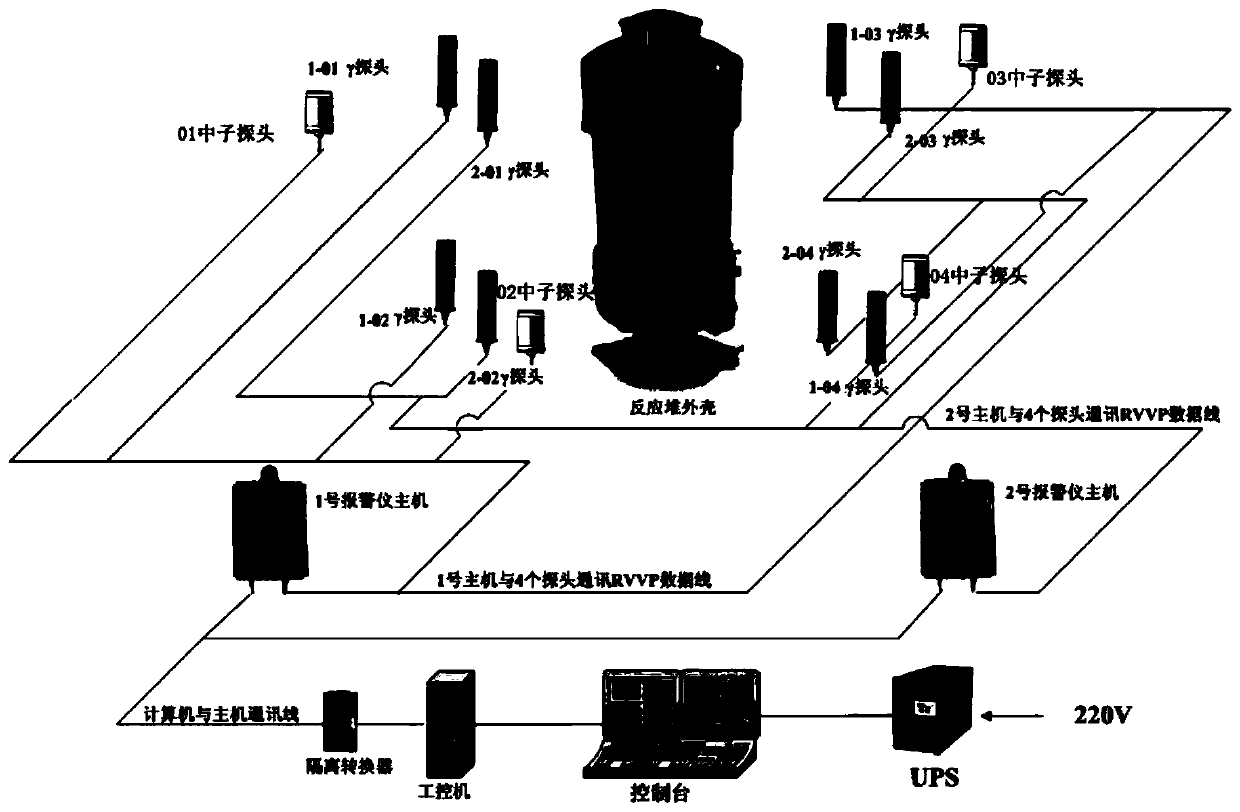

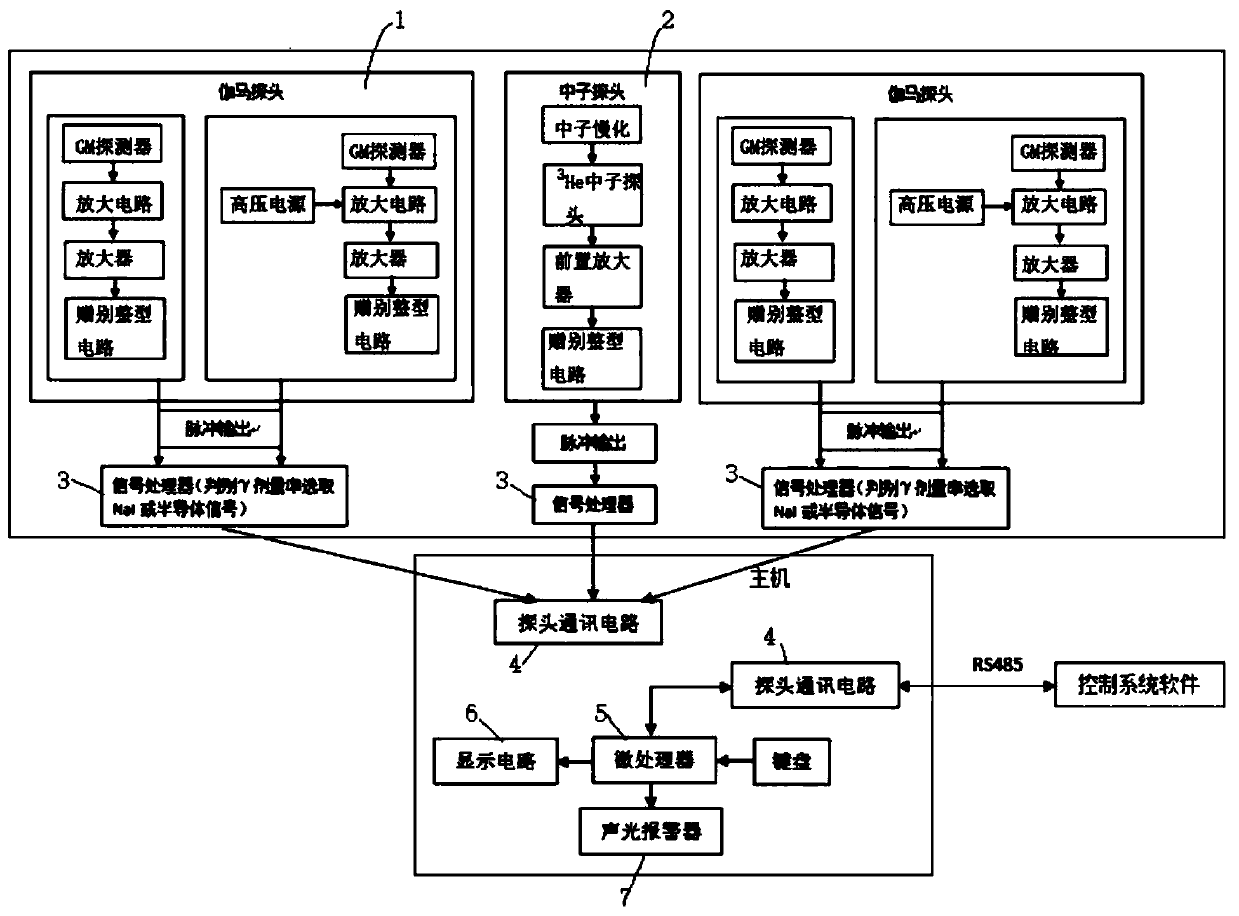

Fixed integrated device for monitoring regional gamma neutron radiation

PendingCN111366964ASimplify complexityExtended energy rangeDosimetersNeutron radiation measurementNuclear powerNeutron radiation

The invention relates to a fixed integrated device for monitoring regional gamma neutron radiation. The device comprises a gamma detector, a neutron detector and a host system connected with the gammadetector and the neutron detector through an RS-485 communication network, wherein the host system is connected with a detection signal processing and display system, the gamma detector comprises a plurality of gamma probes, the neutron detector comprises a plurality of neutron probes, the detection signal processing and display system comprises a signal processor connected with the gamma probesand the neutron probes, and the signal processor converts detector signals of the gamma probes and the neutron probes into digital signals. The device is advantaged in that gamma and neutron dose monitoring and dose data management in complex radiation places such as a nuclear reactor are completed by using one dose monitoring system, a GM detector and a 3He proportional counter are selected as main detection instrument probes and are organically combined into a region gamma and neutron detection device, the monitor is beneficial to simplifying equipment complexity of a radiation monitoring system in a nuclear power facility place, and the arrangement space is saved.

Owner:CHINA INST FOR RADIATION PROTECTION

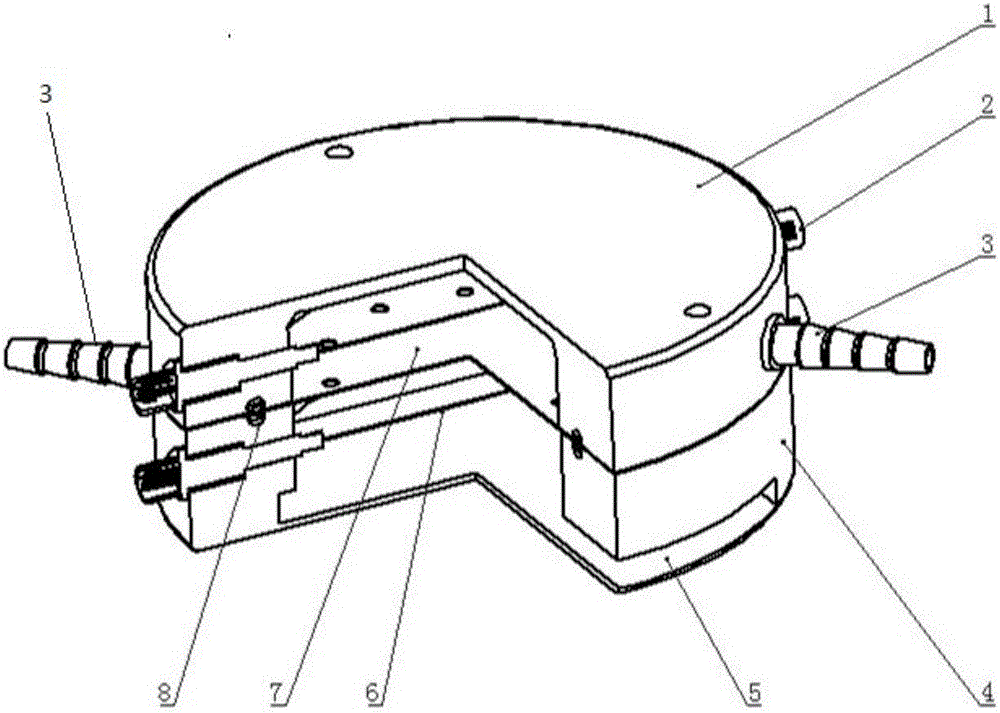

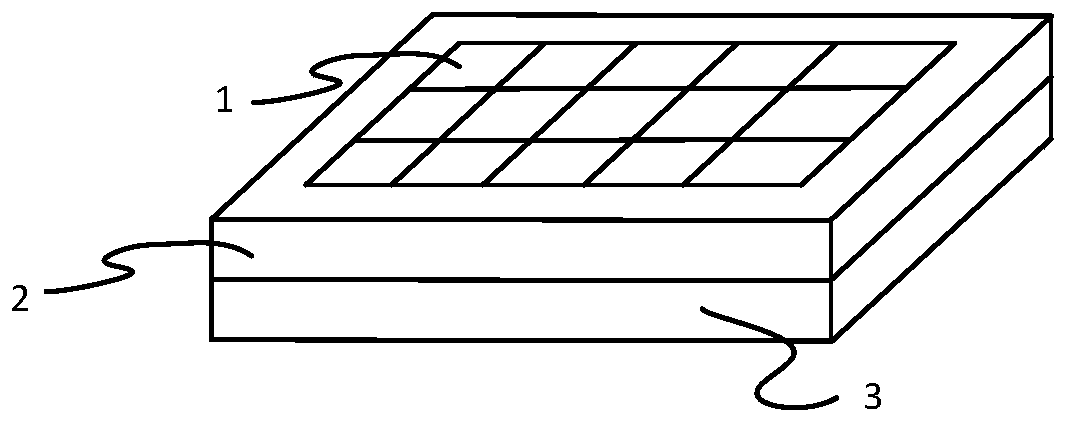

Multifilament proportional counter

InactiveCN105629285AMaintain stabilitySteady shakingRadiation intensity measurementEmissivityRadioactive waste

The invention relates to a multifilament proportional counter. The multifilament proportional counter is characterized in that an upper cover plate is disposed on a pedestal in a covered manner; a tray support is disposed on the upper part of the pedestal, and is combined with the pedestal; a tray is disposed on the upper part of the tray support, and is connected with the tray support; a cathode bottom plate is fixedly disposed on the upper cover plate; a connecting rod is fixedly disposed on the lower part of the cathode bottom plate; an anode filament rack is disposed on the lower part of the cathode bottom plate, and is hung on the connecting rod; and anode filaments are connected with the anode filament rack by springs. The multifilament proportional counter is advantageous in that the influence of the distance between the radioactive source and the anode filaments on the emissivity of the radioactive source surface and the uncertainty evaluation can be researched quantitatively, and the influence of the air pressure working condition on the beta ray detection can be researched quantitatively; the electric field distribution is stable, and can be used to keep the tray used for carrying the large-area source stable and unshaken, and by adopting the roller-type bearing design, the movable operation of the source tray can be realized.

Owner:NAT INST OF METROLOGY CHINA

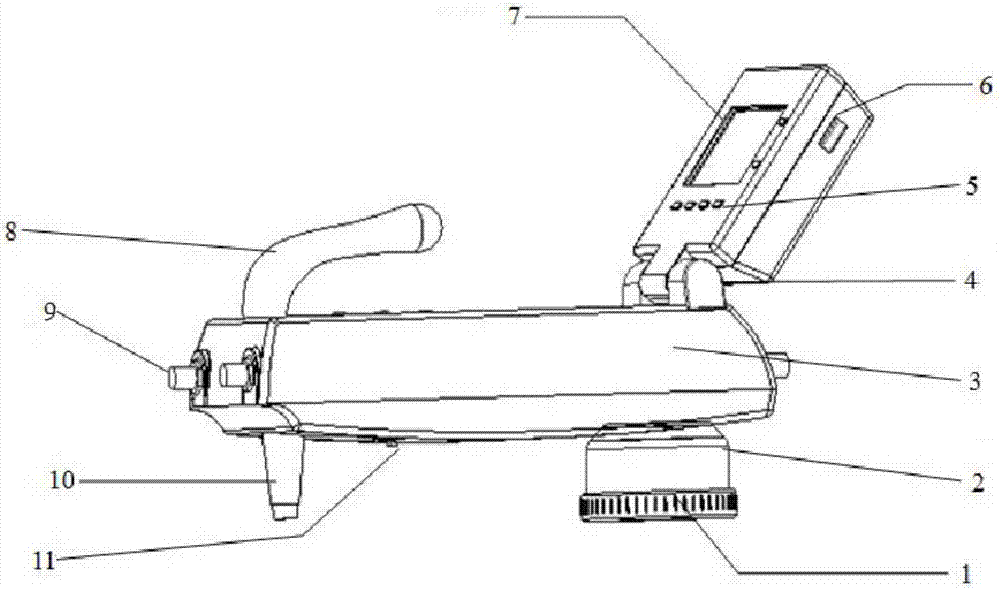

Tritium surface pollution measuring instrument

InactiveCN107144869AReduce manufacturing costHigh detection sensitivityX/gamma/cosmic radiation measurmentSignal processing circuitsMeasuring instrument

The invention provides a tritium surface pollution measuring instrument, comprising a detector, a measuring instrument main machine, a display screen, an air inlet mouth, and a support leg. The detector is a gas-flow-type proportional counter and is formed by a metal hemispherical-shaped cathode and a metal annular-shaped tungsten wire anode in the cathode. The measuring instrument main machine comprises a signal acquiring module, a signal processing circuit, a microprocessor, a power supply module, a data communication module and a counting control and display circuit. The anode of the detector is connected with the output of the power supply module and is connected with the input of the signal acquiring module through a signal line. The signal acquiring module is connected with the signal processing module so as to be connected with the microprocessor. The microprocessor is connected with the power supply module, the data communication module and the counting control and display circuit. The display screen is articulated with the measuring instrument main machine through the display screen articulation chains. The surface and the side face of the display screen are provided with pressing keys and USB interfaces. The other end at the upper surface of the measuring instrument main machine is provided with a handle. The air inlet mouth is arranged at one side of the measuring instrument main machine. The bottom of the measuring instrument main machine is provided with the support leg and a battery box.

Owner:中广核久源(成都)科技有限公司 +1

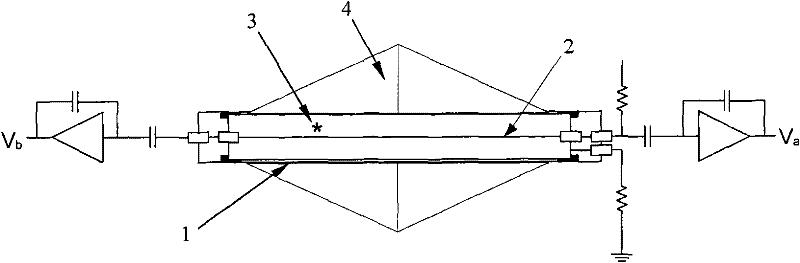

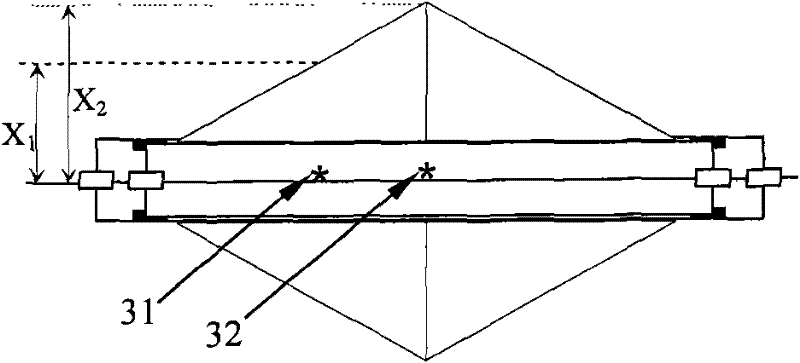

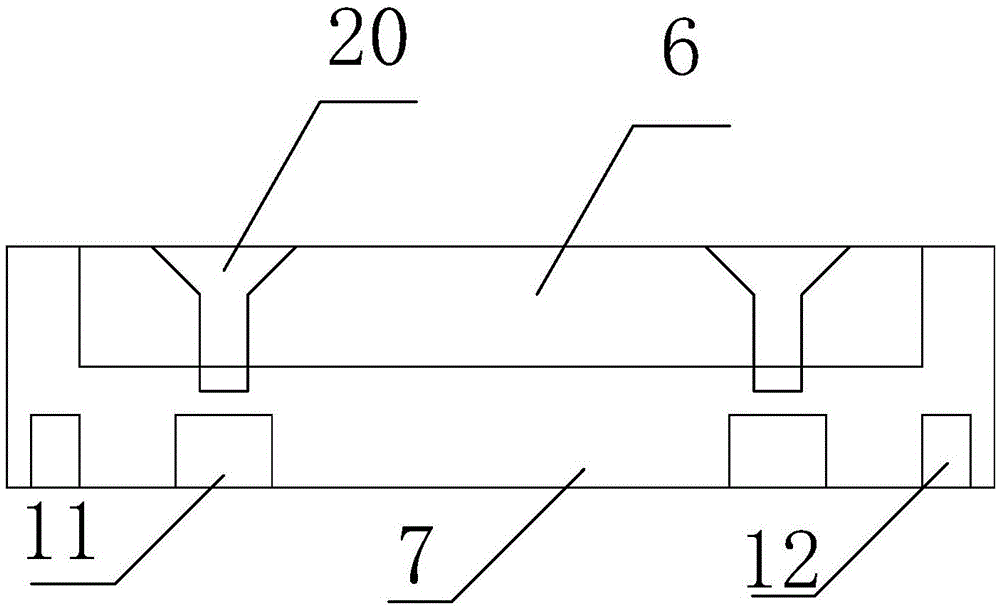

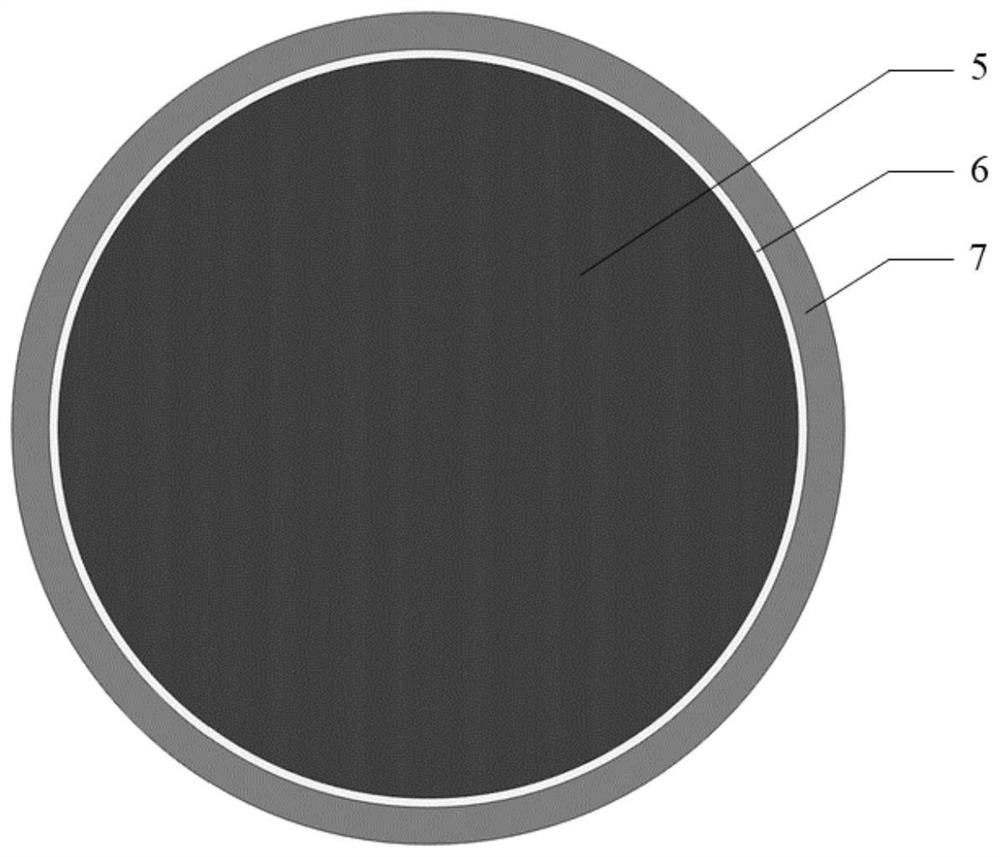

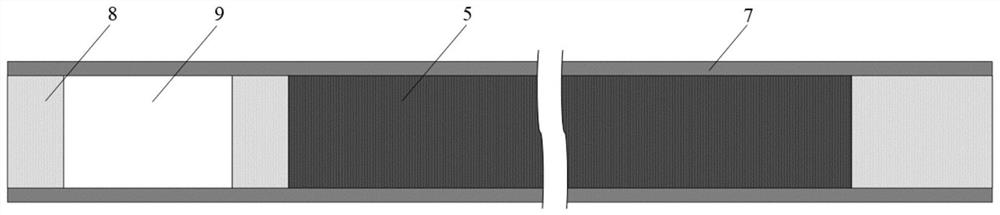

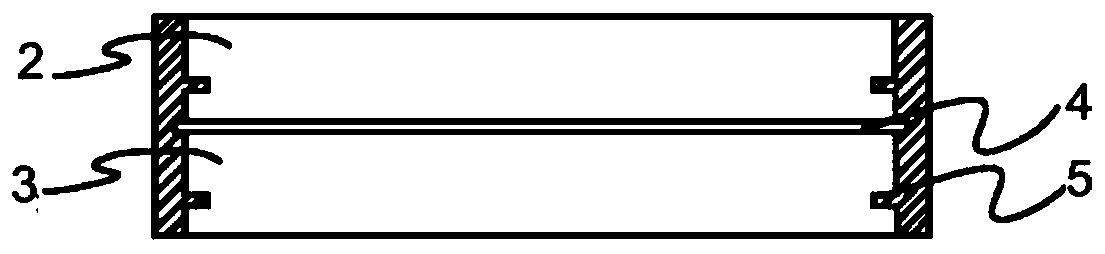

Double-barrelled accordance cylindrical flow-gas proportional counter tube

PendingCN106772535AReduce backgroundImproved energy resolutionRadiation intensity measurementImage resolutionEngineering

The present invention discloses a double-barrelled accordance cylindrical flow-gas proportional counter tube. The tube comprises a cylindrical tube body which is internally provided with an upper cavity and a lower cavity, an isolating membrane is configured to separate the upper cavity from the lower cavity, only obstructs [Alpha] particles and does not obstruct [Beta] particles, the isolating membrane is provided with an air vent hole, a sample room is arranged in the lower cavity, and an upper copper cavity and a lower copper cavity are respectively connected with ventilation interfaces; and the cylindrical tube body is earthed, the upper cavity and the lower cavity are internally provided with anode wires, and the upper cavity and the lower cavity respectively output mutually independent pulse signals at the normal work state. The problems are solved that a traditional flow-gas proportional counter tube is high in housing background and bad in resolution ratio, and [Alpha] and [Beta] perform mutual crosstalk when the total [Alpha] activity and the total [Beta] activity are measured at the same time.

Owner:上海新漫传感科技有限公司

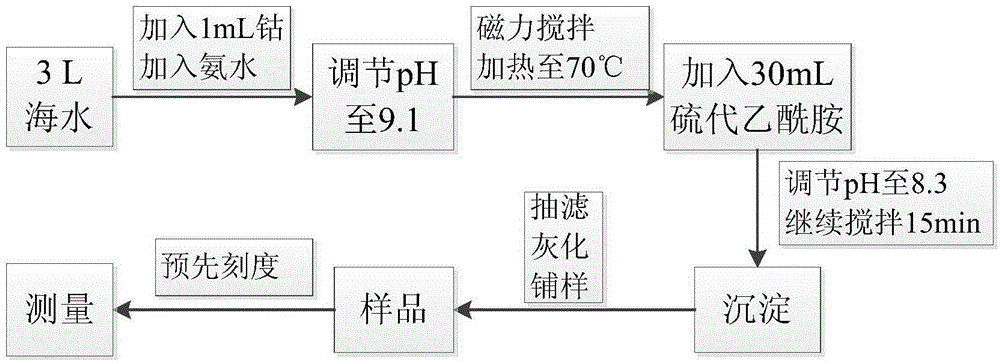

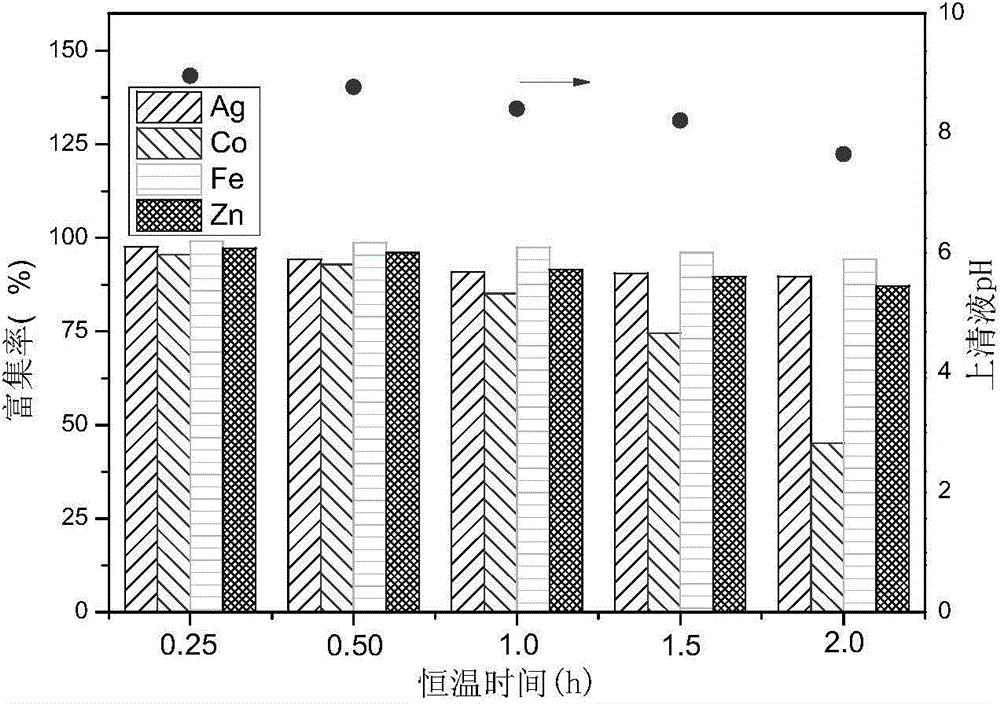

Method for measuring activity concentration of kalium-subtracted total beta radionuclides in seawater

ActiveCN104898151AHigh enrichment rateUniform precipitationRadiation intensity measurementSeawaterNuclear facilities

The invention relates to a method for measuring the activity concentration of kalium-subtracted total beta radionuclides in seawater, and the method is characterized in that the method comprises the following steps: (a) adding a cobalt carrier into used seawater, forming cobalt ion solution, adjusting the pH value of the cobalt ion solution to be greater than seven, and then adding thioacetamide into the solution to form cobalt sulfide sediments through reaction; (b) extracting and putting the cobalt sulfide sediments under the temperature from 600 DEG C to 800 DEG C for ashing; (c) adding porphyrized ashing products to a measuring disc, adding an ethyl alcohol sample, and putting the mixture on a flow-gas type proportional counter for measurement and calculation. The method achieves the measurement of beta radionuclides with the enrichment ratio being greater than 95% which is discharged into the seawater in an operation process of nuclear facilities, such as 58Co, 60Co, 59Fe, 65Zn, 110mAg and so on, thereby guaranteeing that the sediments prepared through the method are more uniform and moderate in weight. The detection lower limit is 3mBq / L, so the method is suitable for the monitoring of the activity concentration of kalium-subtracted total beta radionuclides in seawater, and is also suitable for heavy-salt water similar to a seawater sample, and heavy-salt water which contains radionuclides and is obtained through processing.

Owner:SUZHOU NUCLEAR POWER RES INST +3

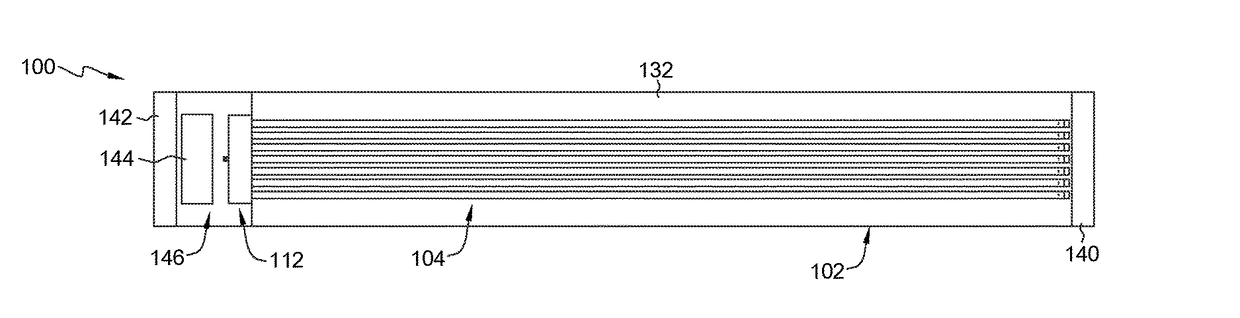

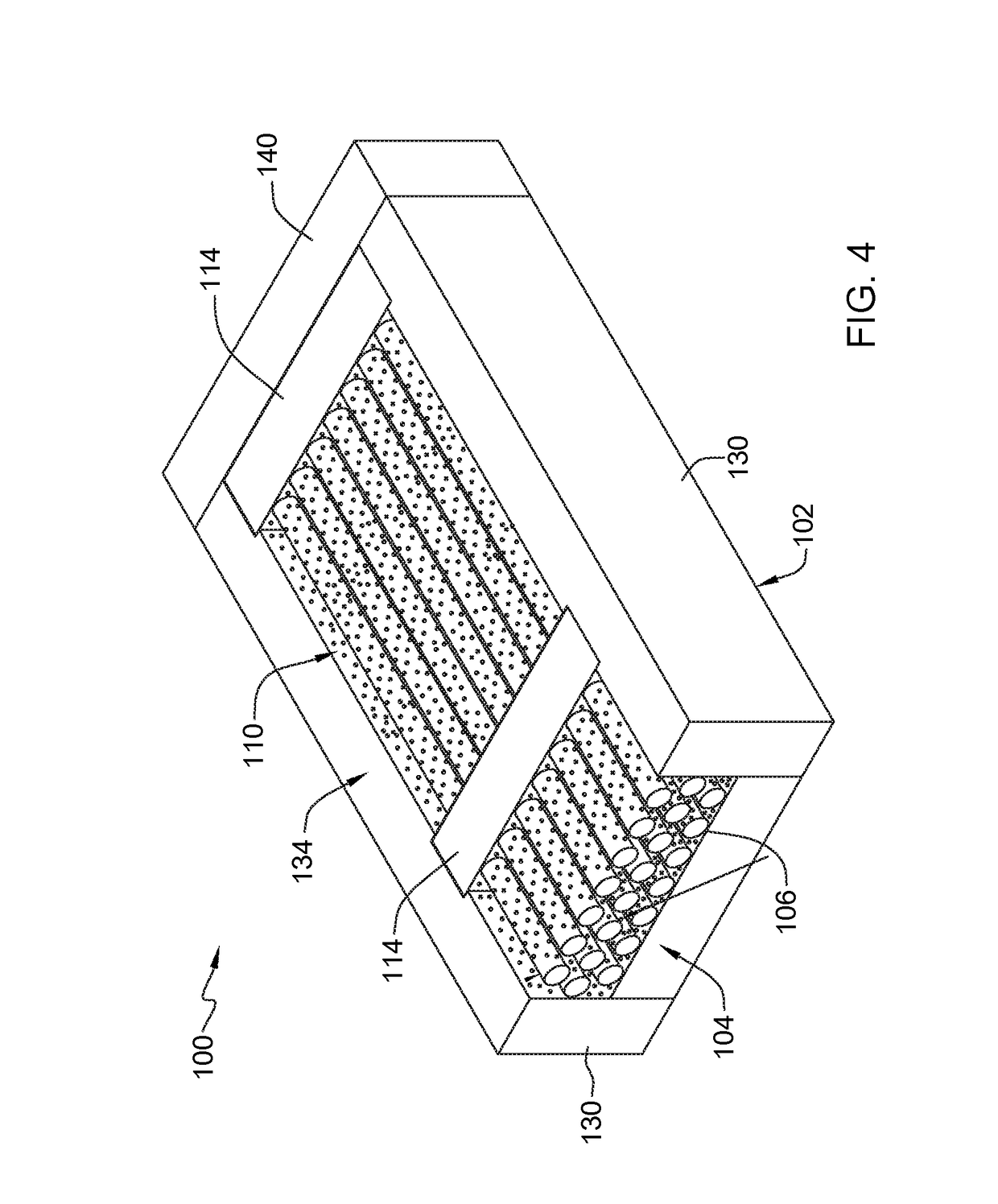

Neutron detector using proportional counters

ActiveUS9678229B2High sensitivityImprove efficiencyMeasurement with semiconductor devicesElectric discharge tubesElectrical conductorComputer module

A neutron detector module comprising a distribution of proportional counters positioned in a defined array. Each of the proportional counters includes a supply of a neutron sensitive gas for reacting with neutrons, and this reaction generates ionizing reaction products. The proportional counters include a multitude of tubes, and each of the tubes has a diameter between 0.50 inch and 1.00 inch. The neutron detector module comprises further a multitude of electrical conductors; and each of the conductors is positioned in one of the proportional counters, and the ionizing reaction products generate electric current pulses in the electrical conductors.

Owner:LND

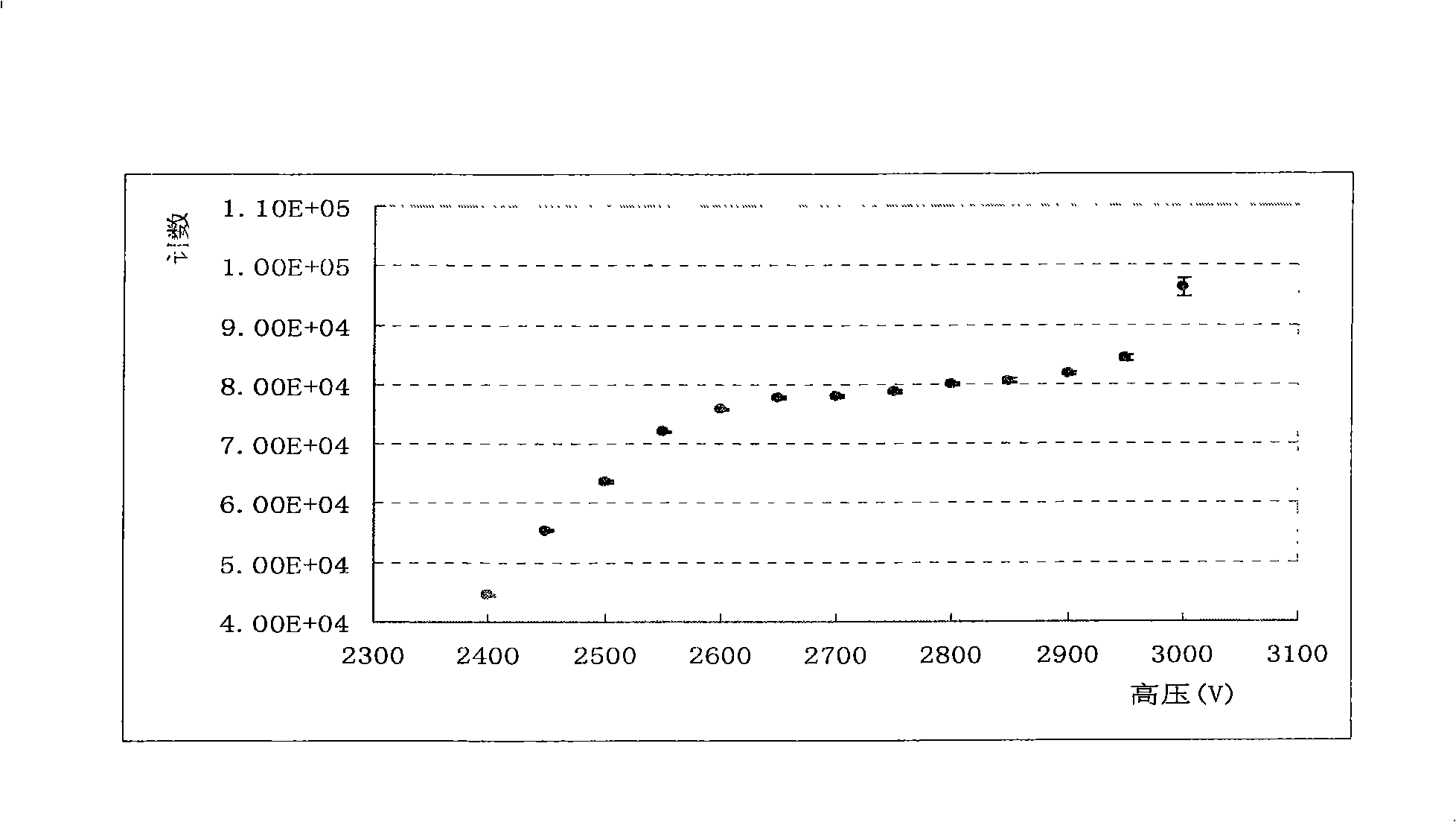

Manufacturing process of closed-gas large-area proportional counter used for measuring alpha and beta radioactive surface contamination

ActiveCN103487823ASimple processRadiation intensity measurementNuclear radiationSolid state detector

The invention belongs to the field of nuclear radiation detectors, and particularly relates to a manufacturing process of a closed-gas large-area proportional counter used for measuring alpha and beta radioactive surface contamination. The manufacturing process comprises the following steps: designing the shell of a detector, selecting manufacturing materials, cleaning and passivating the materials, assembling and fixing the shell of the detector, cleaning an incident window, cleaning and fixing anode wires, pasting the incident window, displacing gas, performing sealing, and finally testing all performance indexes. The manufacturing process is simple and feasible and does not need special equipment; the closed-gas large-area proportional counter manufactured through the manufacturing process is still virgin ground in domestic proportional counters; according to the finished closed-gas large-area proportional counter manufactured through the manufacturing process, the plateau length can reach 200V under the plateau slope of 5% per 100V, the efficiency of measuring a 90Sr-90Y beta radioactive source and a 239 Pu alpha radioactive source respectively in the mode of tightly attaching to the surface of the incident window is more than 70% and more than 30% respectively, counting life is not shorter than 1.0E12, and shelf-life is more than one year. Thus, the proportional counter can get rid of the limit on a gas cylinder and on the gas circuit facilities of the gas cylinder when used in the alpha and beta radioactive surface contamination; besides, from the point of view of technology and use, a closed-gas proportional detector has the advantages of both a solid state detector and a gas-flow proportional detector.

Owner:SHANXI ZHONGFU NUCLEAR INSTR CO LTD

X fluorescent multi-element analyser

ActiveCN101021494AReduce labor intensityProtection from radiation damageMaterial analysis using wave/particle radiationFluorescenceX-ray

An X fluorescent multi-element analyzer contains an exciting source, an X light tube, a collimator above X light tube, an elementary color filter on front-end of collimator and light tube high-voltage providing energy to X light tube for exciting X-ray. Sample plate has a rotary plate, on which set a sample hole for placing tested sample. Sample hole locates on light path of X-ray calibrated by collimator and appears the same angle as collimator. Probe faces the sample hole positively to receive X fluorescence excited by X-ray. It has a proportional counter tube with a secondary color filter on front-end. A circuit output device connects with probe in series. In the invention, elementary color filter is copper foil and secondary color filter is siliceous film. The invention is a dispersing-type X fluorescent multi-element analyzer with on chemical and radiating pollution and has short measuring time, high precision, simple structure, stable safety and low cost.

Owner:上海爱斯特电子有限公司

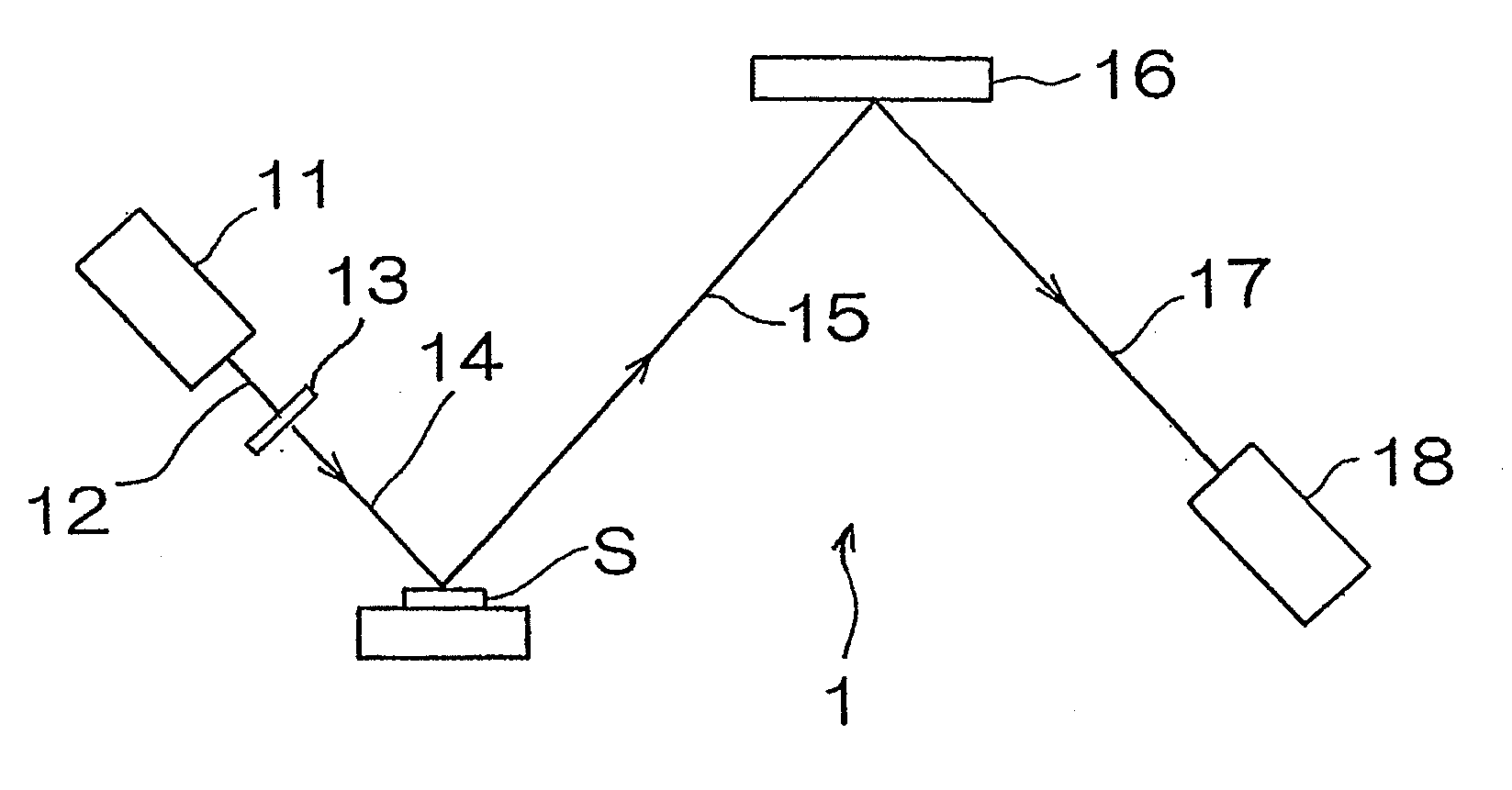

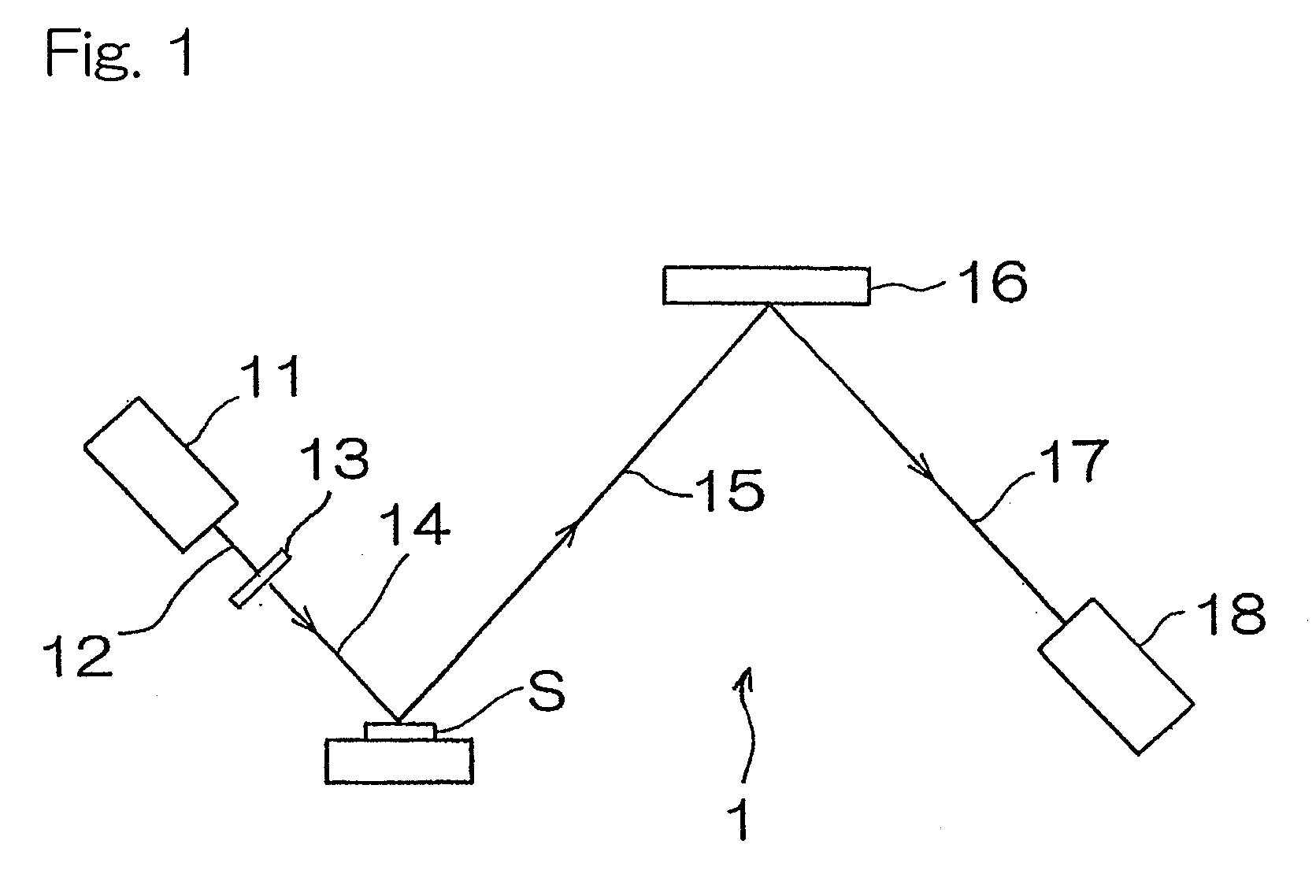

X-ray fluorescence spectrometer

InactiveUS7949093B2Low detection limitBackground intensity can be minimizedMaterial analysis using wave/particle radiationX-ray spectral distribution measurementX-ray filterX-ray

An X-ray fluorescence spectrometer for measuring the concentration of sulfur contained in a sample (S), by irradiating the sample (S) with primary X-rays from an X-ray tube (11), monochromating fluorescent X-rays emitted from the sample (S) with a spectroscopic device, and detecting monochromated fluorescent X-rays with an X-ray detector. The spectrometer includes the X-ray tube (11) having a target with an element including chromium, an X-ray filter (13) disposed on a path of travel of X-rays between the X-ray tube (11) and the sample (S) and having a predetermined transmittance for Cr—Kα line from the X-ray tube (11) and made of a material which is an element of which absorption edges do not exist between energies of S—Kα line and Cr—Kα line, and a proportional counter (18) having a detector gas containing a neon gas or a helium gas.

Owner:RIGAKU CORP

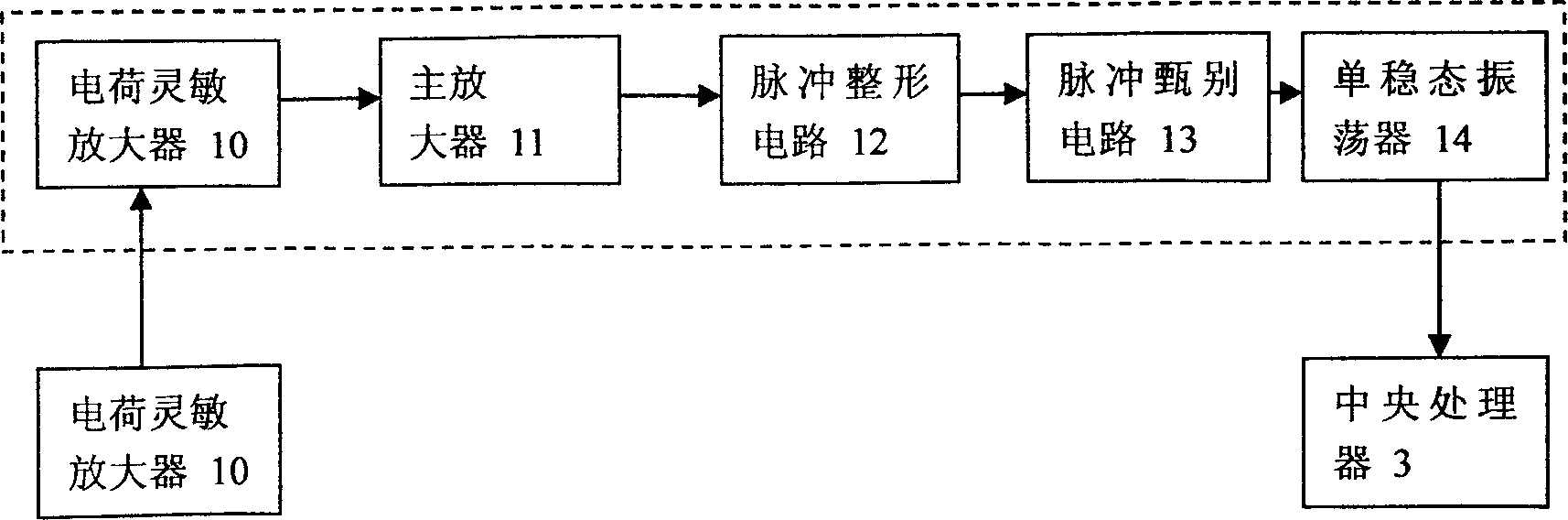

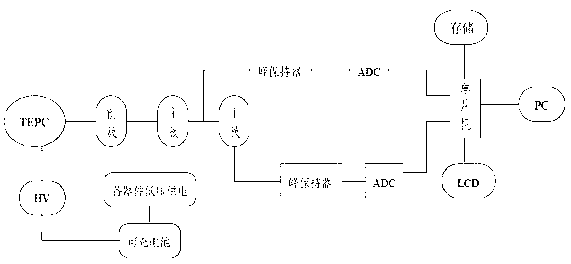

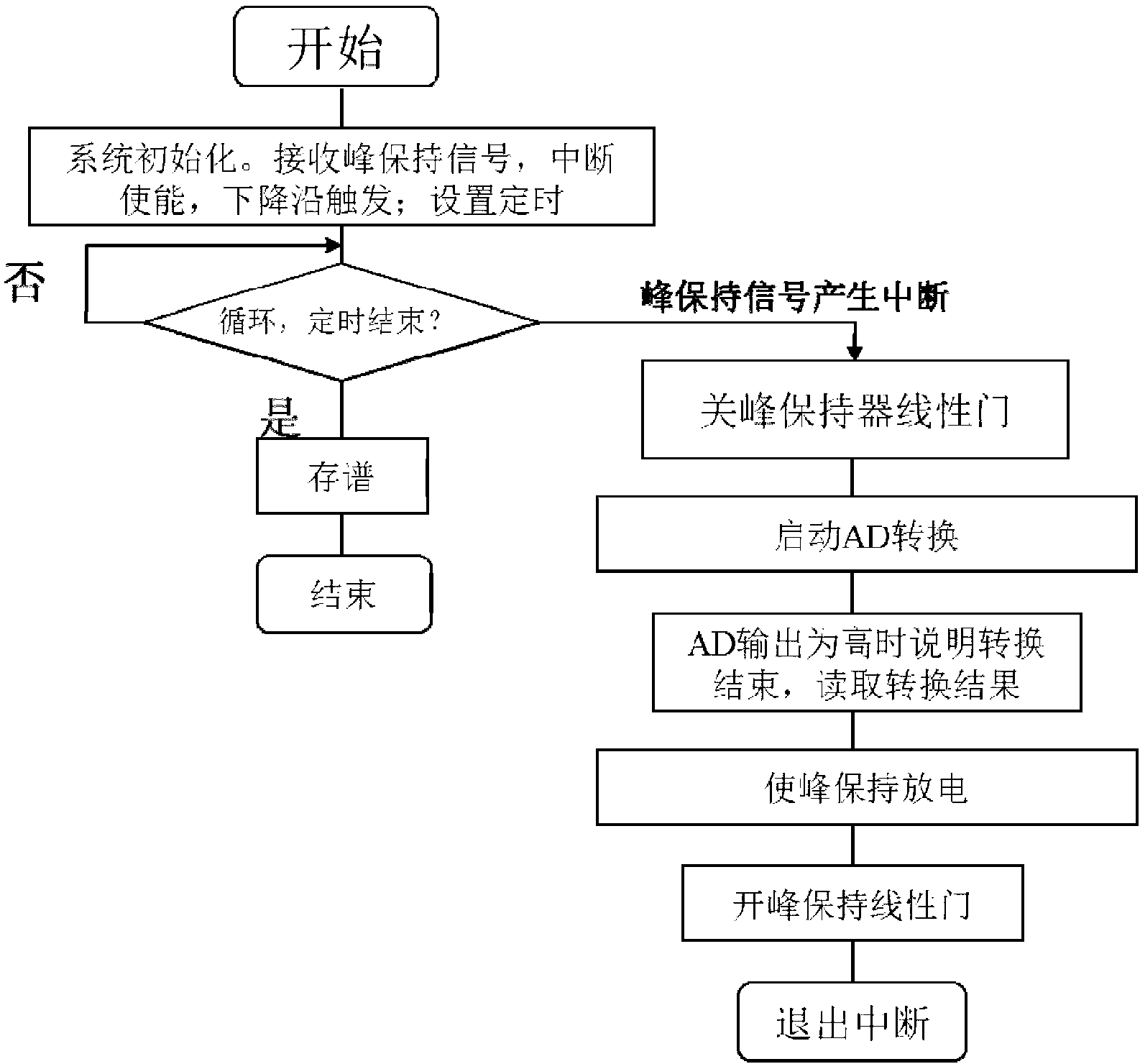

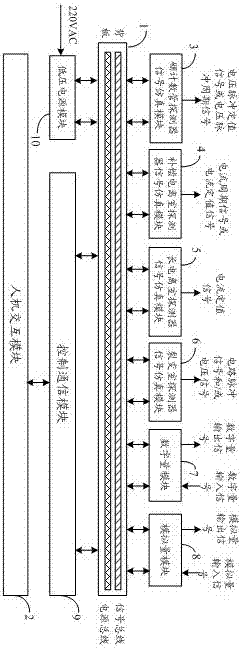

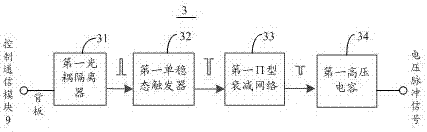

Electronics system of portable low-power-consumption tissue-equivalent proportional counter

ActiveCN103308935AReduce motion commandsReduce computer timeX/gamma/cosmic radiation measurmentSoftware engineeringHemt circuits

The invention relates to an electronics system of a portable low-power-consumption tissue-equivalent proportional counter. The electronics system comprises a pre-amplifier connected with the output end of the tissue-equivalent proportional counter, wherein an output signal of the pre-amplifier is continuously amplified by sequentially passing through two stages of main amplifiers, an output signal of each stage of main amplifier is led out, then respectively passes through a peak retainer and an analog-to-digital converter which are connected with each main amplifier, and are conveyed into a singlechip, and the singlechip programs a threshold so as to control the alternative range of linear energy spectrum data. According to the electronics system, the problems of inaccuracy in measurement and difficulty in control in previous designs are solved; and meanwhile, circuit components are reduced and the circuit power consumption is decreased.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

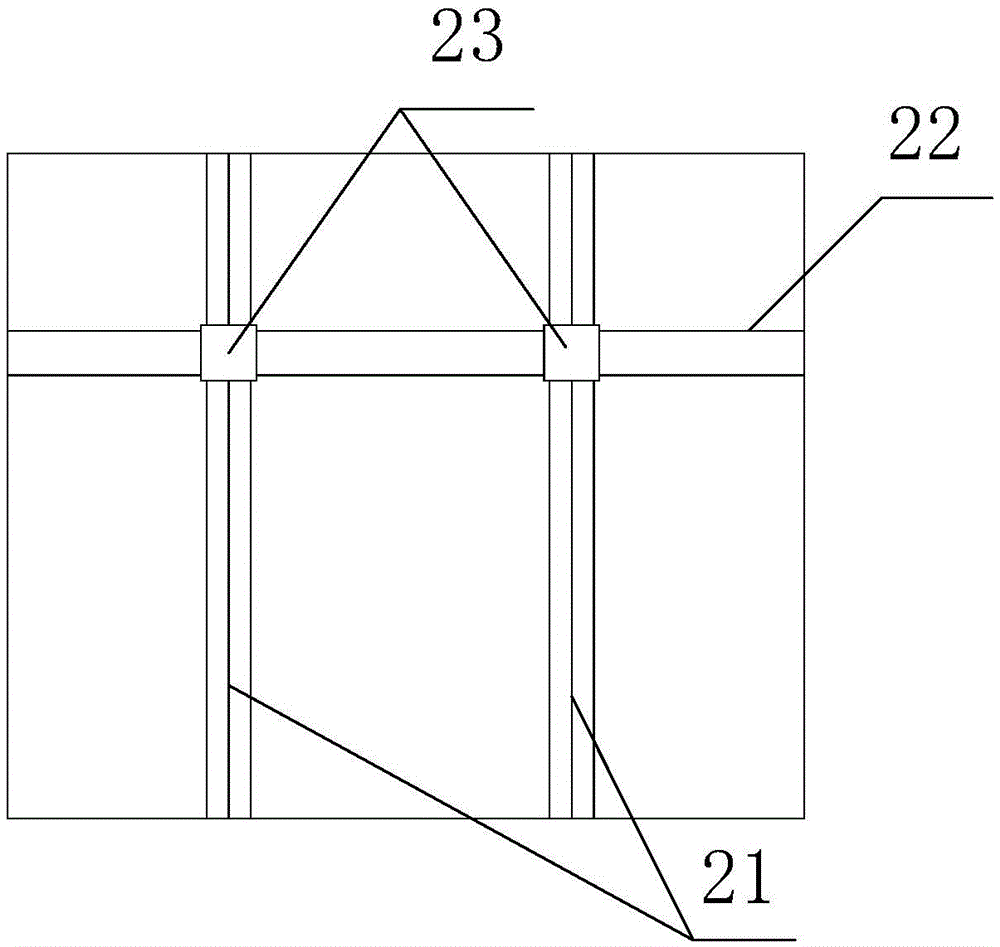

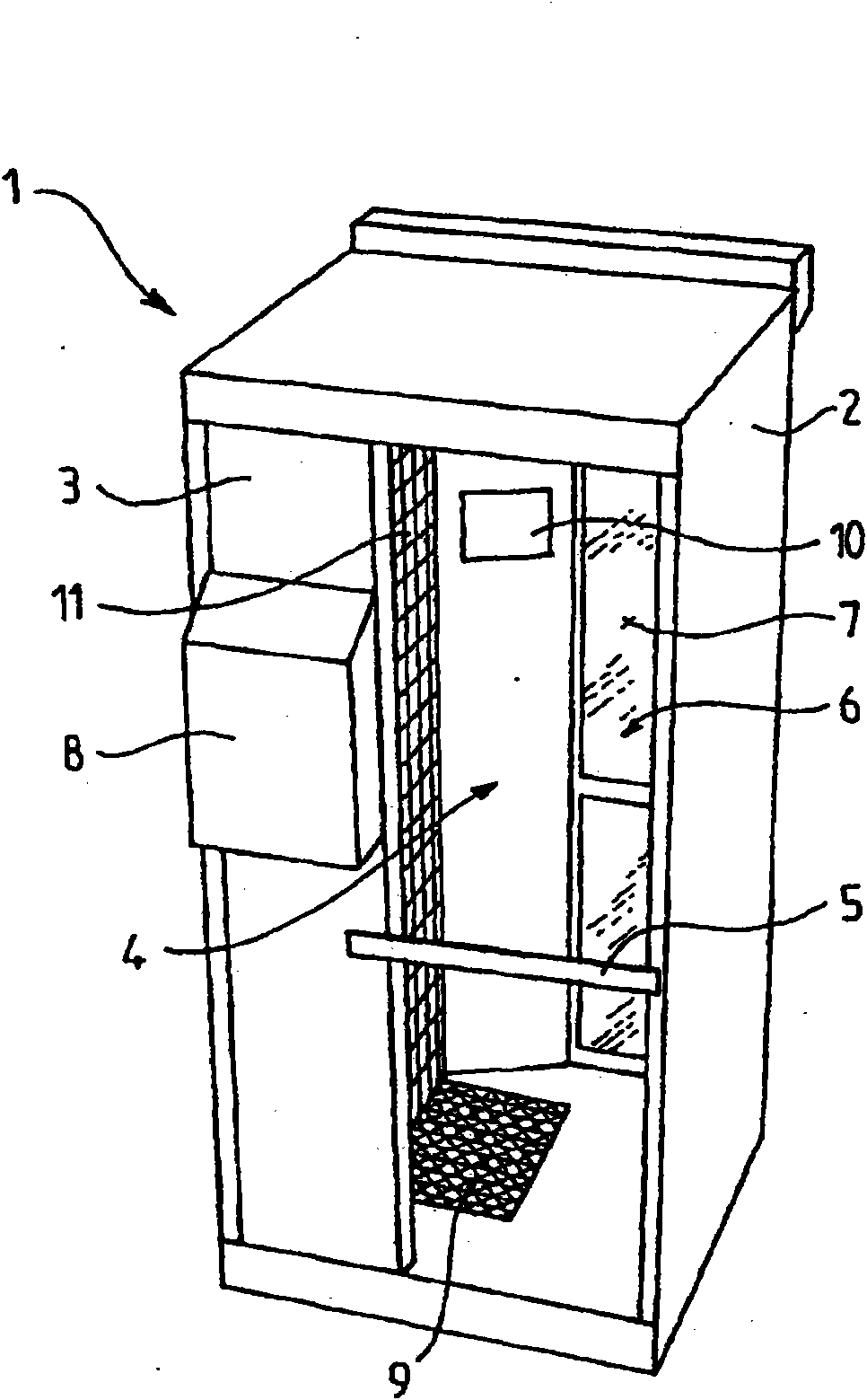

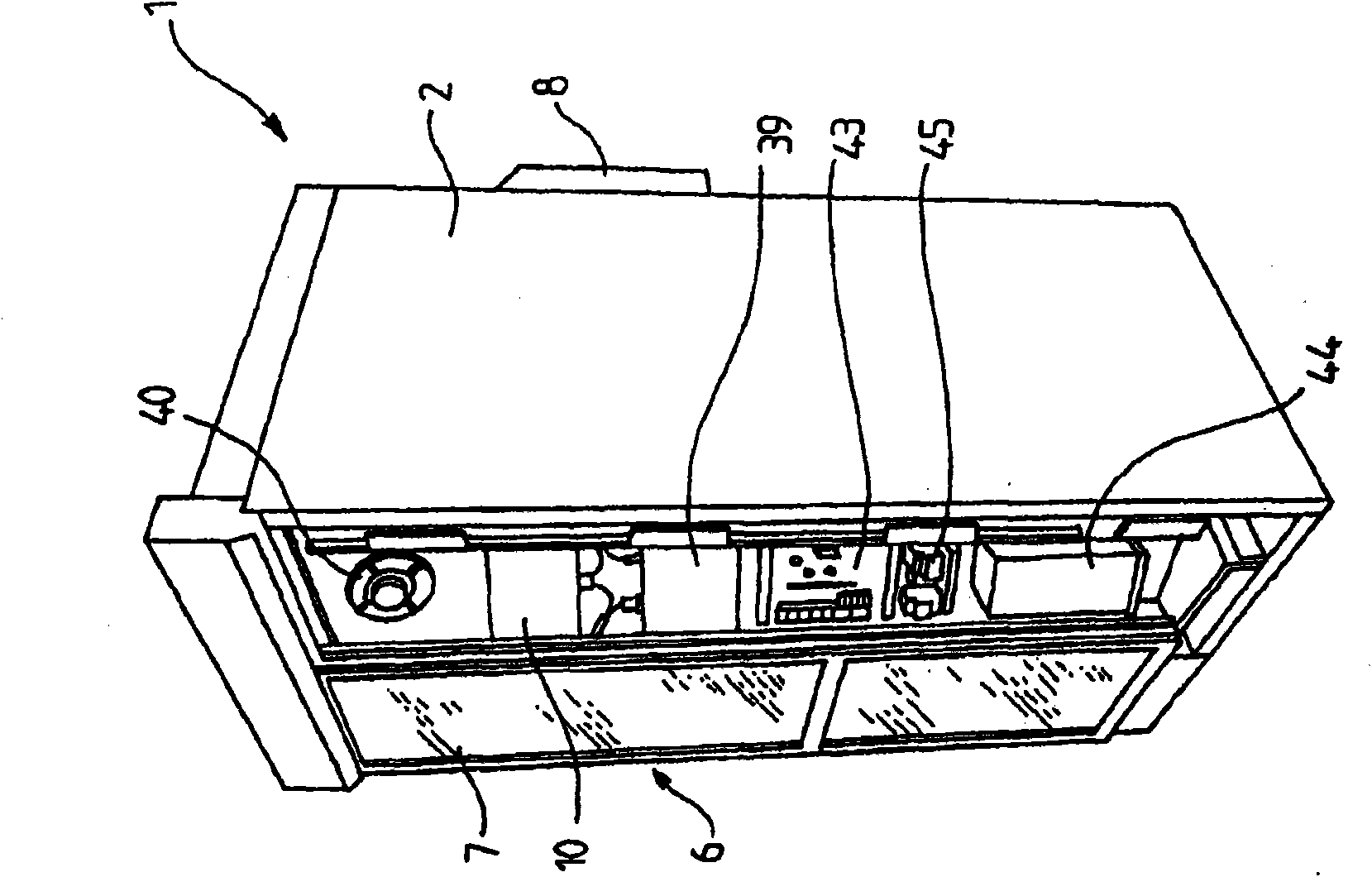

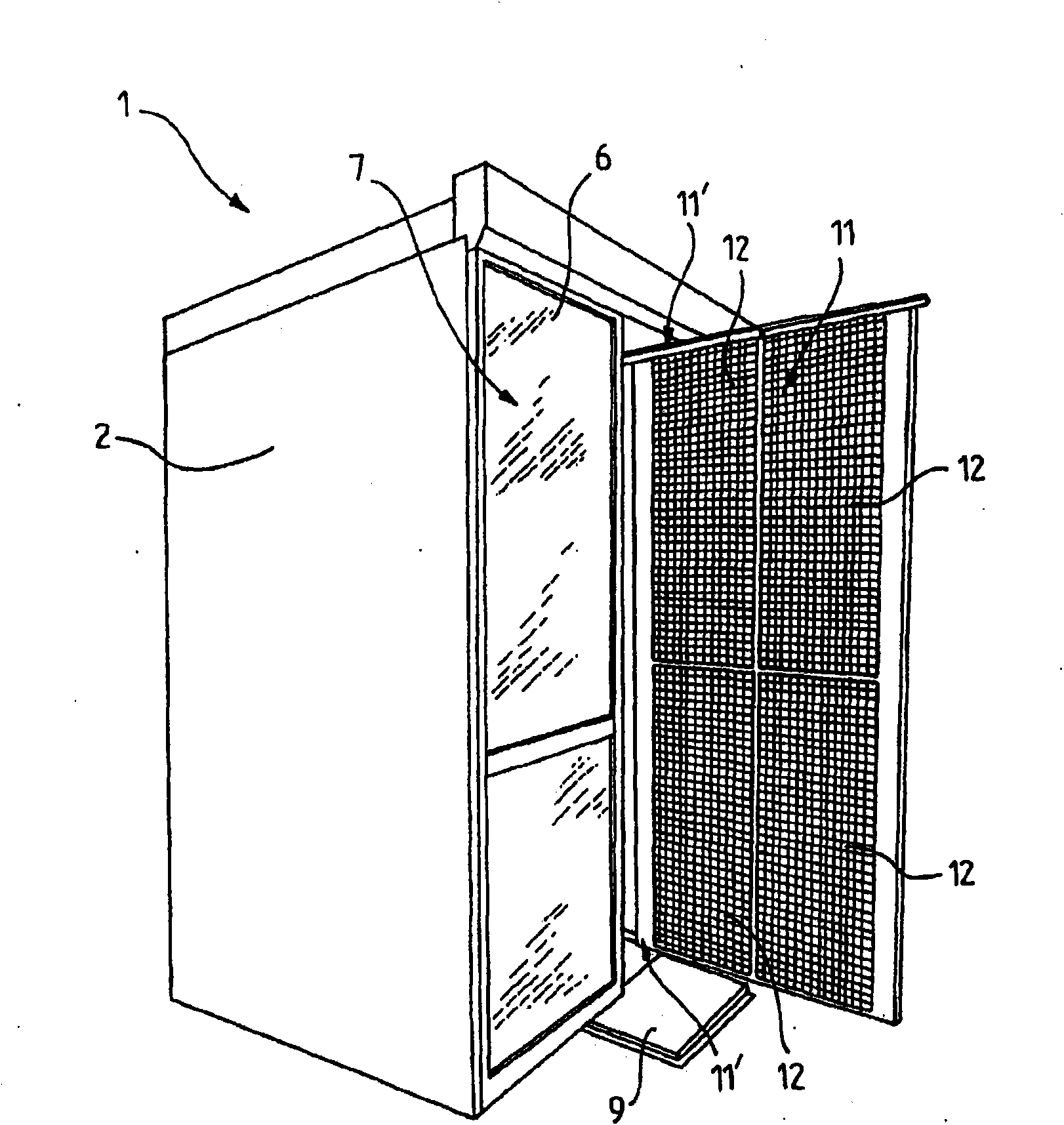

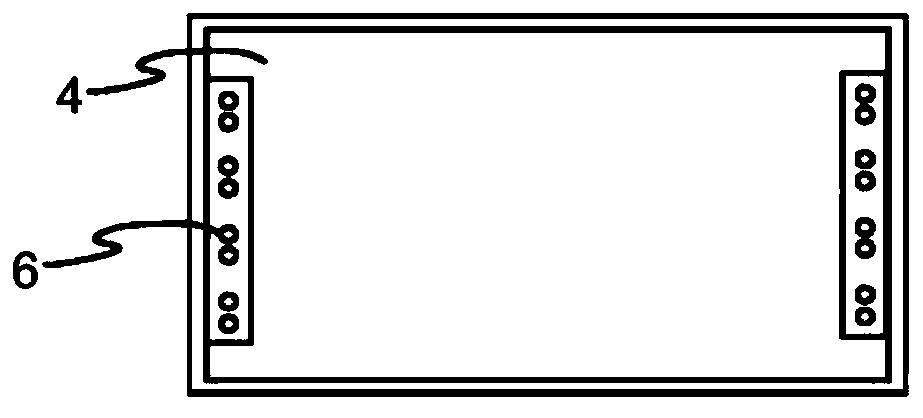

Device and method for monitoring the radioactive contamination of a user

InactiveCN101855574AExtract expansionReduce consumptionRadiation intensity measurementElectrical conductorWhole body

The invention relates to a device (1) and a method for monitoring the contamination of a user by a radioactive element emitting beta radiation, wherein said device includes a user-passage gantry (2) provided with at least two proportional-counter gas-circulation panels (12) capable of detecting the beta radiation emitted substantially over the height of the user oppositely positioned. The gas circuits of the panels are connected in series, each panel (12) of the proportional counter including a frame (21) in the form of a gas-retention parallelepiped tank defining a cathode, at least five parallel anodes (25) evenly arranged across said frame, a sheet (26) of a conducting polymer entirely attached by bonding means (28) on the entire upper edge of said tank, and a conduction metal protection grid (29) of said panel attached and electrically connected to the frame so as to sandwich said sheet. The gas supply circuit of both panels includes a gas supply valve (16) and a control means (18) for opening / shutting said valve and adapted so as to supply the panels with gas at a predetermined rate.

Owner:SAPHYMO

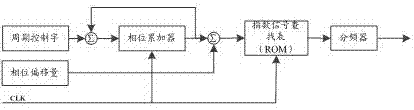

Portable neutron detector signal dynamic simulation device

ActiveCN107204208AEasy to carrySimplify the installation processNuclear energy generationNuclear monitoringPhysicsProportional counter

The invention provides a portable neutron detector signal dynamic simulation device. The device comprises a back plate and a man-machine interaction module, a boron proportional counter tube detector signal simulation module, a compensated ionization chamber detector signal simulation module, a long ionization chamber detector signal simulation module, a fission chamber detector signal simulation module, an analog quantity module, a digital quantity module and a control communication module which are connected and communicated through the back plate, wherein the man-machine interaction module acquires data input by a user and distributes the data to the boron proportional counter tube detector signal simulation module, the compensated ionization chamber detector signal simulation module, the long ionization chamber detector signal simulation module, the fission chamber detector signal simulation module, the analog quantity module and the digital quantity module through the control communication module and the back plate to generate corresponding simulation signals. By the device, RPN neutron detector output signals and RPN-associated external system output signals are simulated, and a technical means is provided for the equipment debugging, logic function checking and fault detection of an RPN system.

Owner:LINGDONG NUCLEAR POWER +3

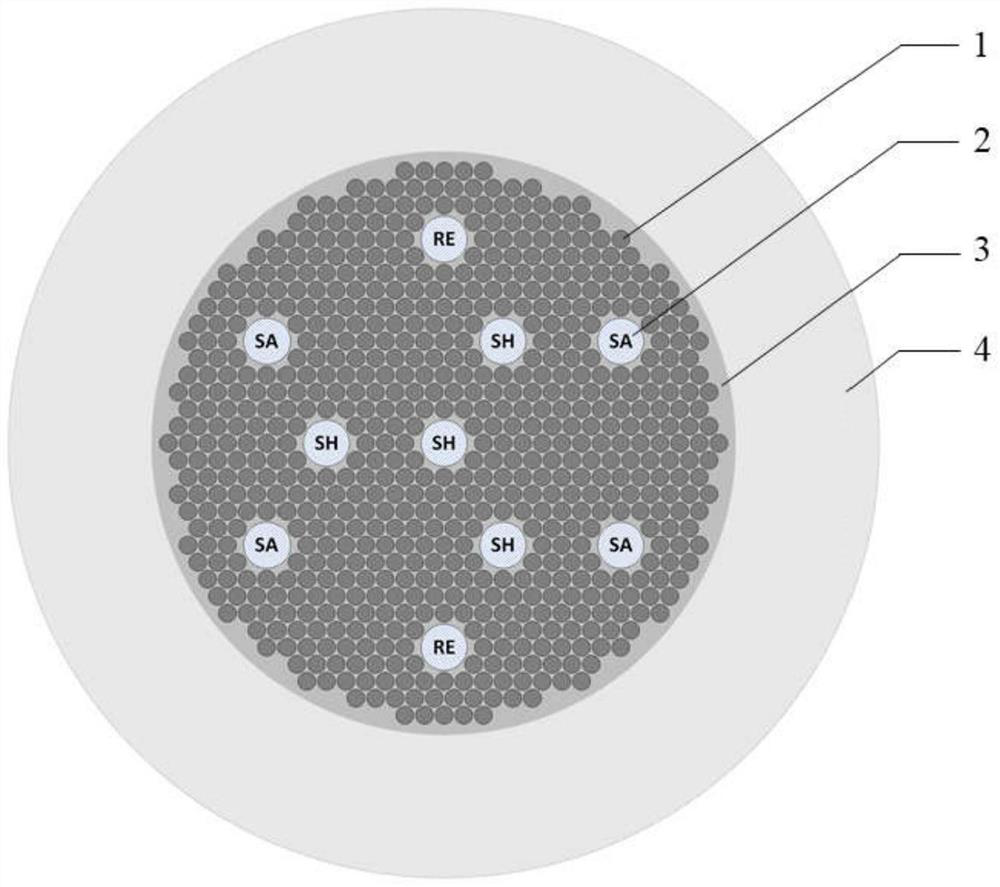

Compact space reactor core structure suitable for passive starting

ActiveCN113436756ACompact layoutReduce volumeNuclear energy generationShieldingUranium oxideNuclear engineering

The invention discloses a compact space reactor core structure suitable for passive starting. The compact space reactor core structure is composed of a fuel area and an external structure. The fuel area consists of a fuel rod, a control rod and a coolant; the fuel area is divided into an inner area and an outer area, and neutron poison with a certain mass fraction is dispersed in the fuel in the inner area and used for flattening radial power distribution; the fuel rod adopts high-concentration uranium dioxide fuel and a high-temperature-resistant molybdenum alloy cladding; the external structure is composed of radial reflecting layers, coolant channels and a source range detector which are alternately arranged, and the radial reflecting layers are used for reflecting neutrons leaked from a reactor core on one hand and acting with protons or alpha particles in a cosmic space to generate neutrons on the other hand when the reactor is started, so that the initial neutron fluence level is improved; sensitive 3He proportional counter tubes are selected as the source range detectors, and the four source range detectors are arranged on the inner side of the metal beryllium in a 90-degree symmetry mode in the radial direction. On the whole, the space reactor core has the characteristics of compact structure and convenience in monitoring.

Owner:XI AN JIAOTONG UNIV

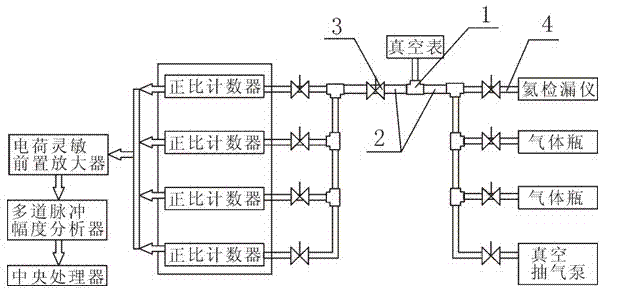

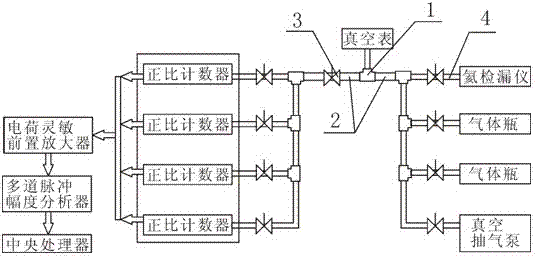

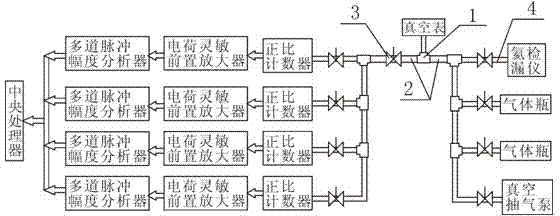

Gaseous tritium activity measuring device

InactiveCN103033838AOvercome the flaws that are not conducive to measurementOvercoming leak-prone flawsRadiation intensity measurementPhysicsProportional counter

The invention discloses a gaseous tritium activity measuring device comprising a detection unit, a signal obtaining unit and a central processor, wherein the signal obtaining unit enables signals detected by the detection unit to form pulse signals in corresponding amplitude and transmits the signals to the central processor for counting, analysis and processing. The device further comprises a vacuum unit, wherein the vacuum unit achieves communication or blocking of connected equipment such as a proportional counter, a helium leak detector, a gas cylinder and a vacuum suction pump through a tee joint and valves so as to bring convenience to vacuumizing of the proportional counter or filling gas in the gas cylinder. The device is simple in structure and strong in operability. Due to the effective vacuumizing method, the device can remove tritium gas remained in the proportional counter and the gas cylinder, lowers the background and detection limit of the detection unit, achieves high-precision and efficient measurement of activity of the low-activity gaseous tritium, and improves detection efficiency of the detection unit.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Low-background anticoincidence closed-gas proportional counter for measuring alpha and beta surface pollution and manufacturing method thereof

PendingCN111474569AReduce backgroundLower minimum detectable limitX/gamma/cosmic radiation measurmentNuclear engineeringGamma ray

The invention relates to a low-background anticoincidence closed-gas proportional counter for measuring alpha and beta surface pollution and a manufacturing method thereof. The counter comprises a measuring chamber, an anticoincidence measuring chamber and a baffle between the measuring chamber and the anticoincidence measuring chamber. The baffle can block alpha rays and beta rays so that cosmicrays and environment gamma rays can pass through the baffle. The manufacturing method comprises the following steps: cleaning each part for the first time; assembling and fixing the components; cleaning the assembled detector again; performing gas replacement and passivation on the detector; and pressurizing, sealing and carrying out performance test. The method has the beneficial effects that theinfluence of cosmic rays and environmental gamma rays can be reduced, so that the background of the detector and the lowest detectable lower limit are reduced, and the performance of radiation measurement is improved. The plateau inclination of the detector is below 3% / 100V, the plateau length is more than 200V, the 90Sr-90Y efficiency of the beta radioactive source measured close to the surfaceof the incident window is greater than 60%. The alpha radioactive source 239 Pu efficiency is larger than 30%, the lowest detectable lower limit of beta is smaller than 0.12 Bq / cm <2>, the lowest detectable lower limit of alpha is smaller than 0.02 Bq / cm <2>, the counting service life is not smaller than 1.0 E12, and the shelving service life is one year or longer.

Owner:SHANXI ZHONGFU NUCLEAR INSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com