Device and method for measuring coating by using X-ray fluorescence spectrometer

A fluorescence spectrometer and X-ray technology, which is applied in the field of coating measurement devices using X-ray fluorescence spectrometer, can solve the problems of large measurement area, product damage, complicated operation, etc., and achieve reduced errors, stable X-rays, and clear images intuitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

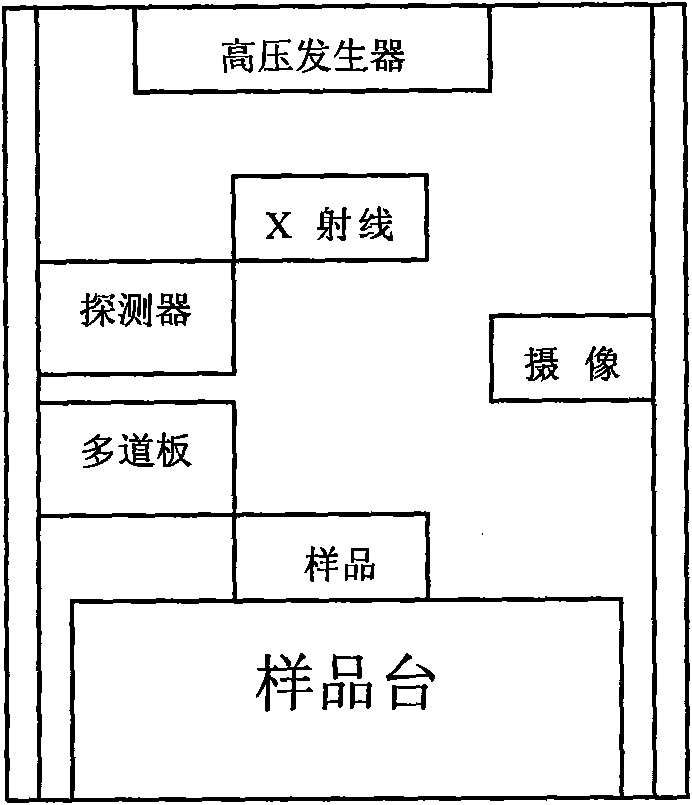

[0041] figure 1 It is the basic structure diagram of X-ray fluorescence spectrometer;

[0042] The X-ray fluorescence spectrometer consists of a high-voltage generator, a detector, a multi-channel plate, and a CCD camera. A high-voltage generator generates X-rays, which irradiate the sample. The sample produces secondary X-rays of different intensities under the irradiation of X-rays, that is, X-ray fluorescence. X-fluorescence is taken with a CCD camera.

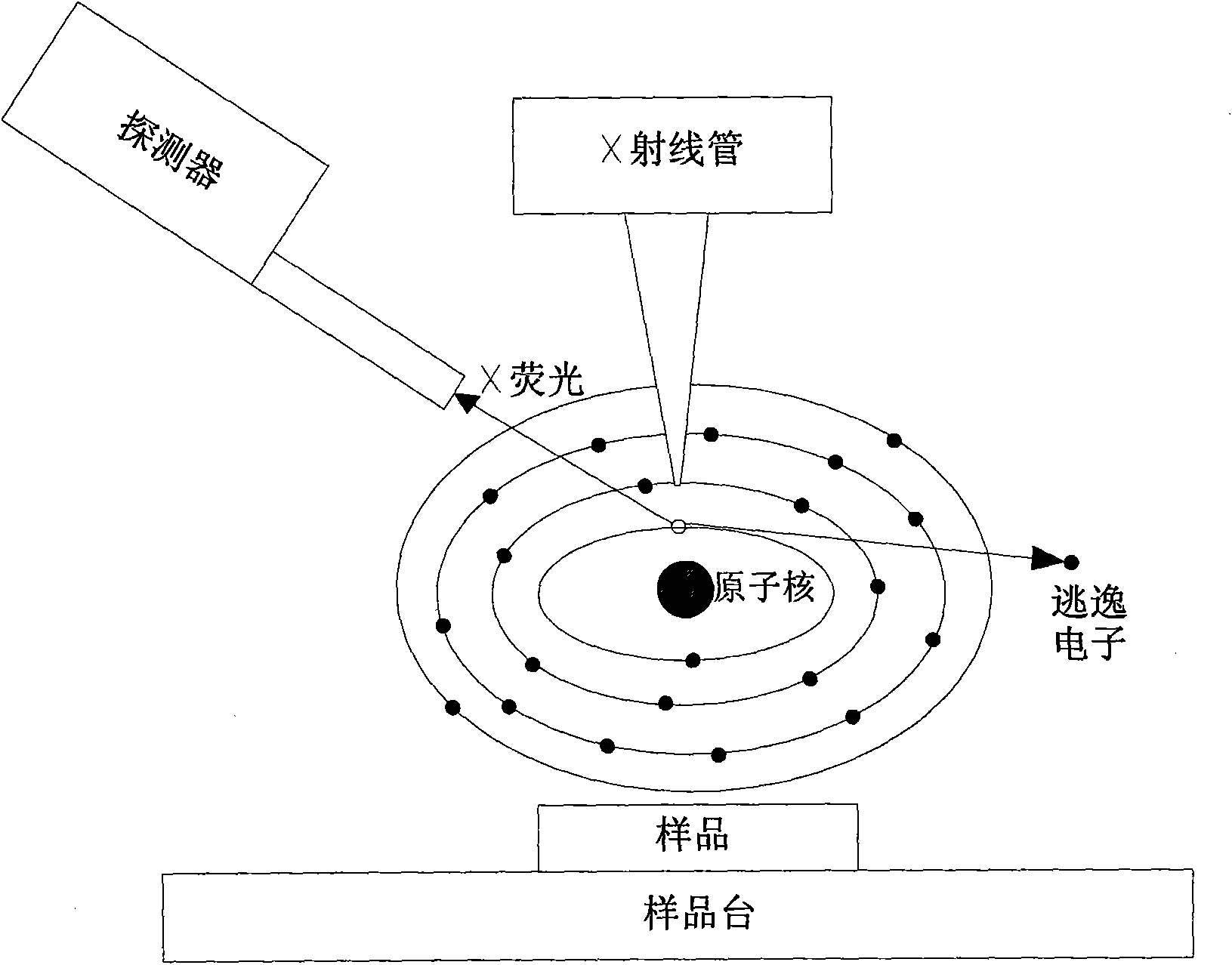

[0043] figure 2 It is the working principle diagram of X-ray fluorescence spectrometer;

[0044] The working principle of X-ray fluorescence spectrometer:

[0045] Fluorescence is the process in which atoms or molecules absorb photons of a certain energy and then release photons of lower energy. X-ray fluorescence is the energy released when the electrons in the inner shell of atoms transition into photons.

[0046] Due to the existence of tube pressure, the cathode generates a large number of electrons to bombard t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com