High-accuracy flexible thin film shape preservation cutting device

A cutting device and flexible film technology, applied in metal processing and other directions, to achieve the effect of simplifying the process, consistent tension, and improving speed and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

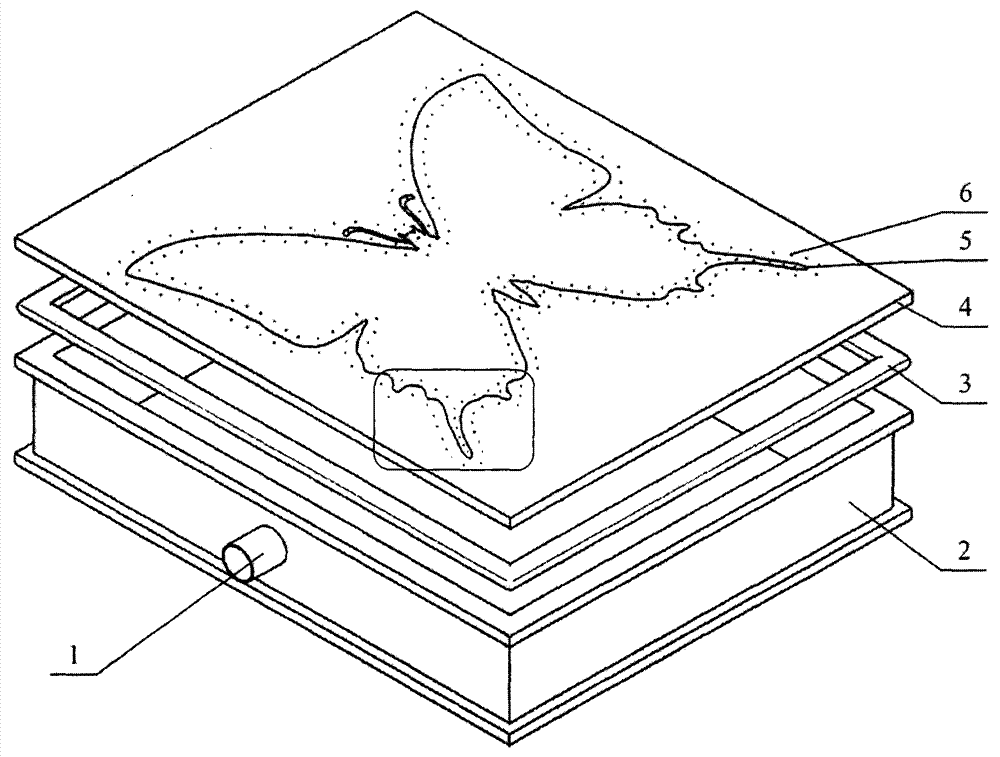

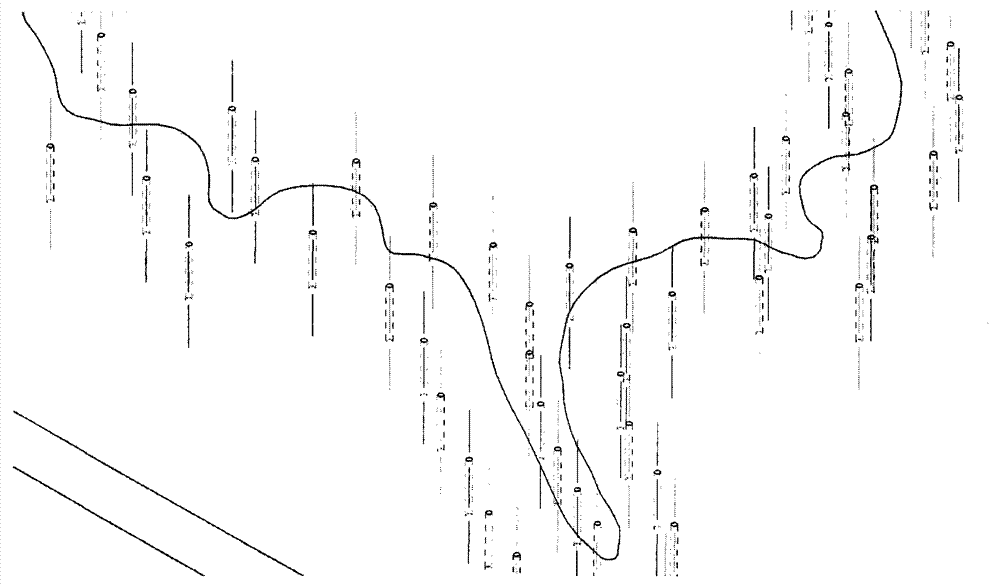

[0012] The parts of the work of the present invention are composed of a vacuum box, a rubber sealing ring and a model plate engraved with a pattern shape that needs to be cut, and need to be used in conjunction with a vacuum pump. The vacuum box is made of 8mm acrylic board, which is a sealed container without a cover, such as figure 1 Shown, have the hole that is used for pumping on the case wall of vacuum box 2, install the suction pipe connector on the hole, use leather tube to be connected with the vacuum pump on the suction pipe connector on the vacuum box. The model plate is also made of 8mm acrylic plate, and the surface of the model plate is engraved with a 1mm deep and 0.2mm wide tool groove along the pattern outline with a two-dimensional engraving machine. Excess air from the acrylic model plate. The gap between the model plate and the vacuum box is sealed tightly with a sealing ring. The sealing ring is sprinkled with water to improve the sealing effect. A closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com