Permanent magnet stepping motor and electronic device

A permanent magnet step and stator technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problem of increasing the gap between cylindrical electric terminals and eliminating the difficulty of circuit board welding, increasing processing costs and defect rates, and affecting terminal pins. Stability and other issues, to achieve the effect of facilitating modular applications, solving plane scratches, and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

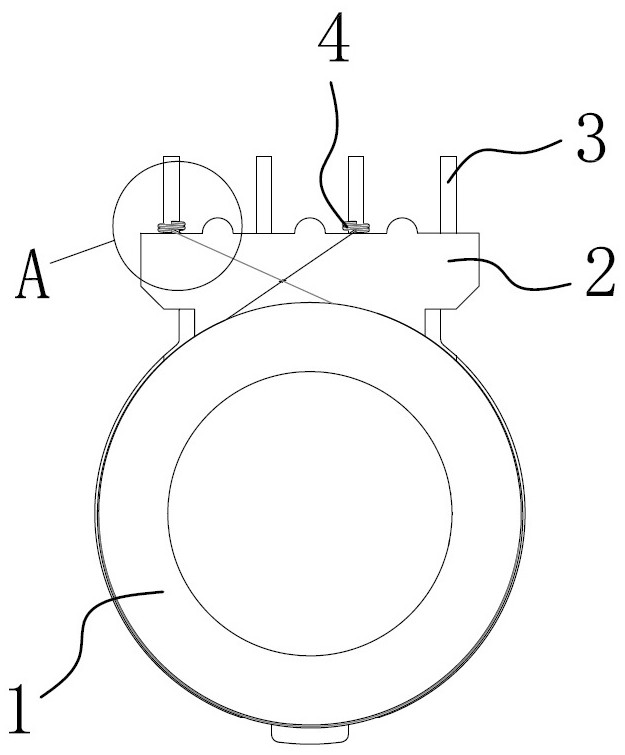

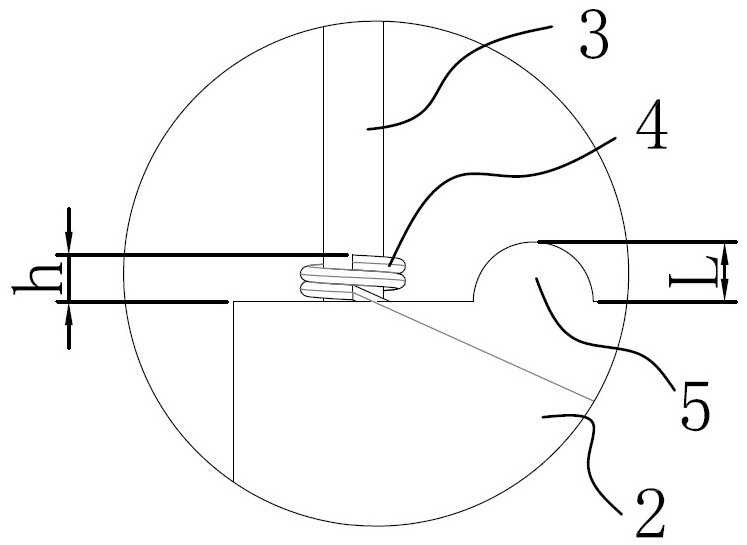

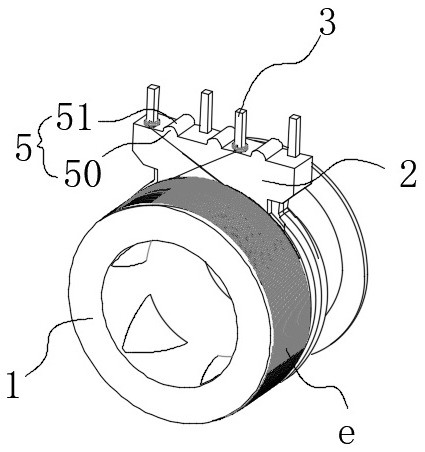

[0069] The protruding anti-damage structure 5 is connected to the protruding platform 2 and protrudes from the end surface of the protruding platform 2 provided with the terminal pin 3;

[0070] The convex height h of the convex damage prevention structure 5 from one end surface of the convex platform 2 to the highest point of the convex damage prevention structure 5 is equal to or greater than the axial direction of the conductive terminal 4 after being axially compressed into place. Length L.

[0071] Such as Figure 10 As shown, the motor also includes a rotor c, which passes through the stator b and the rotor c can rotate relative to the stator b; after the coil e of the stator b is energized, it cooperates with the magnetic field of the rotor c to make the rotor c rotate at a rotation angle of The actual control angle is set.

[0072] Such as Figure 4-5 As shown, the motor also includes a circuit board 6, on which there is an insertion hole 60 for inserting the termin...

Embodiment 2

[0102] The structure and principle of this embodiment are basically the same as those of Embodiment 1, the difference is that: the protruding anti-injury boss 50 is in the shape of a column, which is directly arranged on one end surface of the above-mentioned outer protruding platform 2 .

[0103] Of course, it can also be a columnar convex anti-injury boss and a strip-shaped anti-injury boss arranged on one end surface of the above-mentioned outer convex platform 2, and this embodiment does not carry out the anti-injury for different shapes of the outer convex Bosses are exhausted.

Embodiment 3

[0105] The structure and principle of this embodiment are basically the same as those of Embodiment 1, the difference is that the protruding anti-injury boss 50 is distributed along the length direction of one end surface of the above-mentioned outer protruding platform 2 . Pay attention to avoid enamelled copper wires when distributing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com