A rotary jacking mechanism and an agv trolley including the rotary jacking mechanism

A technology of jacking mechanism and rotating motor, which is applied in the direction of motor vehicles, lifting frames, lifting devices, etc., can solve the problems of inability to rotate, cannot better meet the needs of flexible handling and loading and unloading of goods, and is prone to tilting, etc., to achieve space occupation Small size, simple structure, good self-locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

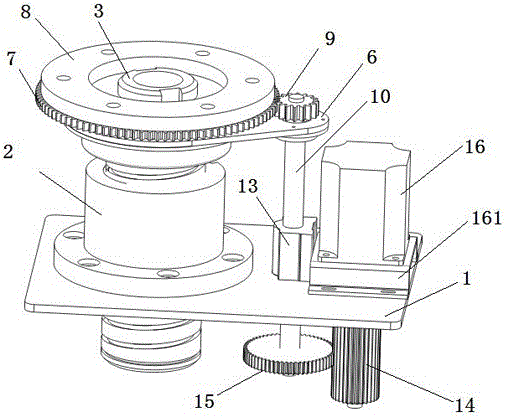

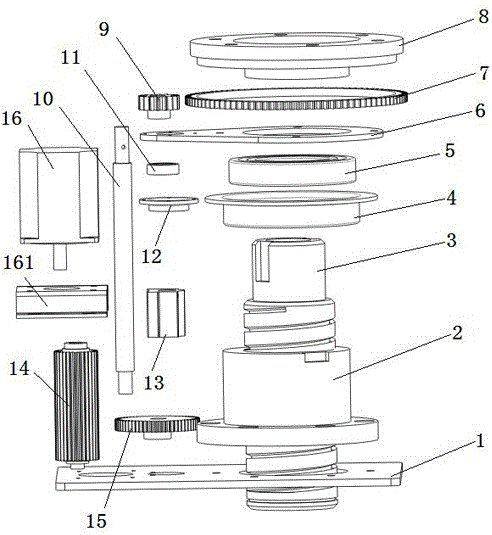

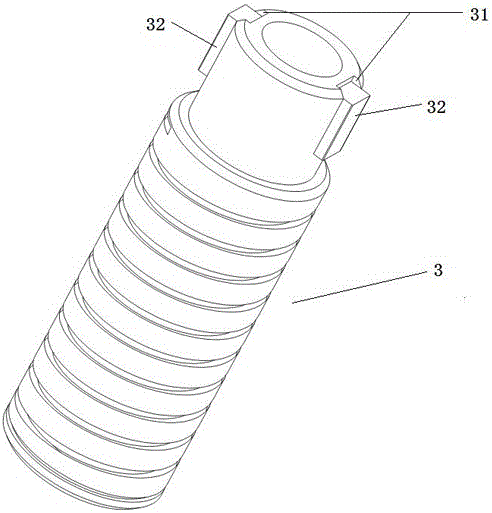

[0029] figure 1 Shown is the three-dimensional structural diagram of the rotary jacking mechanism of the present invention. The rotary jacking mechanism comprises a base fixed plate 1, a rotating motor 16, a transmission assembly, a leading screw 3, a leading screw nut 2, a large bearing bracket 4, a large bearing 5 and a pallet 8. The transmission assembly includes a driving gear 14 , a primary transmission gear 15 , a guide rod 10 , a secondary transmission gear 9 , a gear ring 7 and a linkage plate 6 . The rotating motor 16 is fixed on one side of the upper surface of the base fixing plate 1 by a rotating motor fixing bracket 161. The rotating motor 16 has a built-in motor shaft (not shown in the figure), and the motor shaft is connected to the transmission assembly . The lead screw 3 runs through the base fixing plate 1, and the lead screw 3 is supported on the base fixing plate 1 by the lead screw nut 2, and the transmission assembly is connected with the lead screw 3 a...

Embodiment 2

[0035] Figure 5 Shown is the side sectional view of the AGV trolley comprising the rotary jacking mechanism of the present invention, the AGV trolley includes a walking mechanism consisting of two drive wheels 20 and four universal wheels 21, a vehicle body frame 22, and a vehicle body for the AGV. The battery pack 23, two driving motors 17, two right-angle driving motor reduction boxes 19, one driving motor driver 18, tray support 24, two control panels, navigation device and two are installed on the front of the car and the car respectively, which dolly provides power. Tail infrared sensor. The four universal wheels 21 are positioned at the four corners of the body frame 22, and the two drive wheels 20 are positioned on both sides of the body frame 22, and are installed side by side on the body frame 22 top in turn. The battery pack 23, the rotary jacking mechanism and the driving motor driver 18. The rotary jacking mechanism supports the base fixing plate 1 by a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com