Shockproof insulation bolt structure of machine tool

A technology for bolts and machine tools, applied to the structure of shock-proof insulating bolts of machine tools and the field of bolt structures, can solve the problems of increasing costs, reducing equipment installation efficiency, standardization of fastening bodies and poor interchangeability, and achieving the effect of increasing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

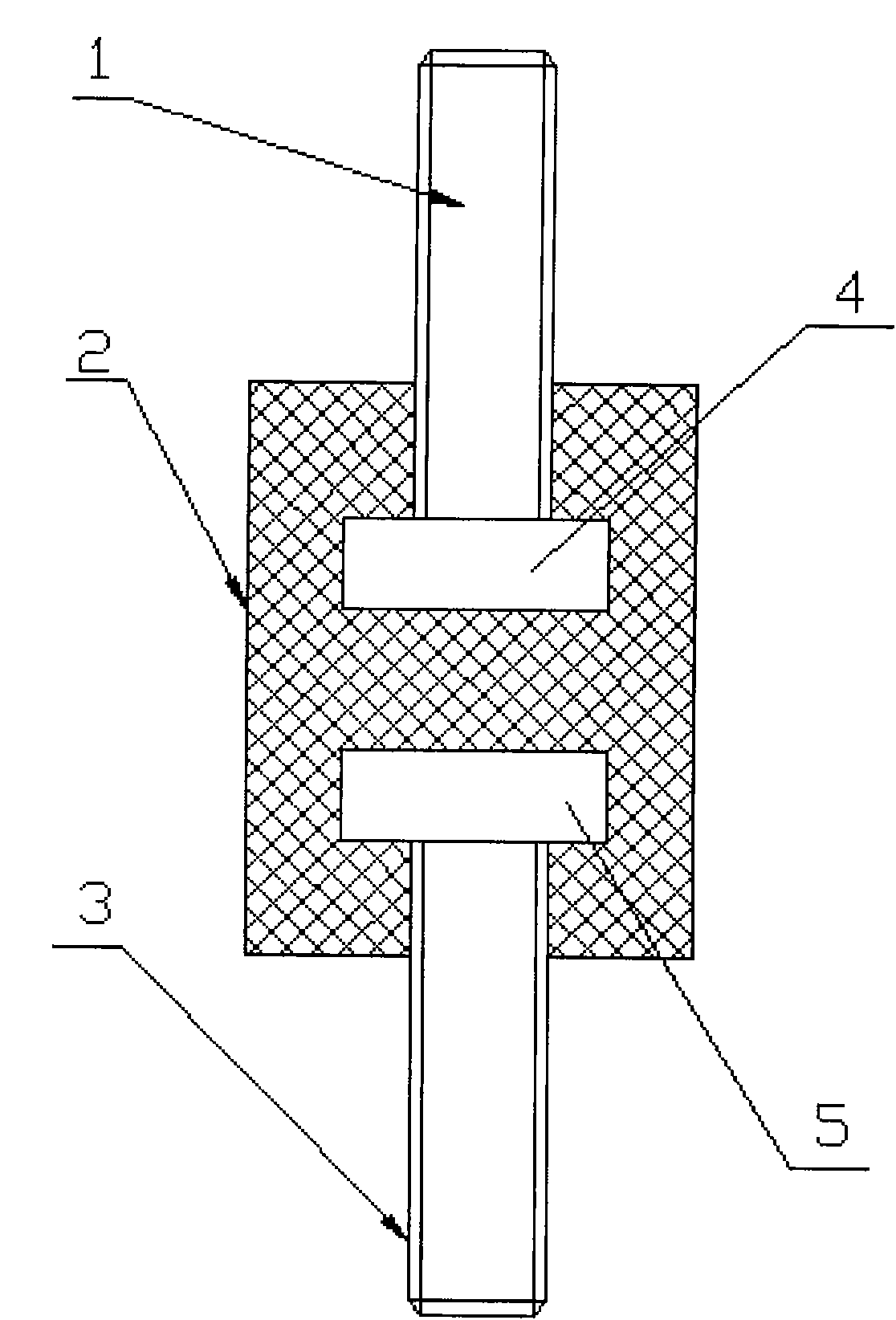

[0009] The structure of the shockproof insulating bolt of the machine tool has an upper bolt (1) and a lower bolt (3), and an upper flange (4) and a lower flange (5) are respectively arranged at both ends of the upper bolt (1) and the lower bolt (3). The upper bolt (1) and the flanged end of the lower bolt (3) are placed opposite to each other, and the axes of the two are fixed coaxially; the connecting body (2) is made of elastic insulating rubber, and the connecting body (2) is used to connect the The upper bolt (1) and the lower bolt (3) are covered together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com