Automobile power-assisted steering motor rotor bearing lining

A technology for power steering and motor rotors, which is applied to the rigid brackets of bearing components, bearing components, shafts and bearings, etc. It can solve the problems of short service life, vibration noise of bearings and bearing housings, easy axial movement, etc., to avoid The effect of excessive axial load, elimination of vibration and noise, and elimination of axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

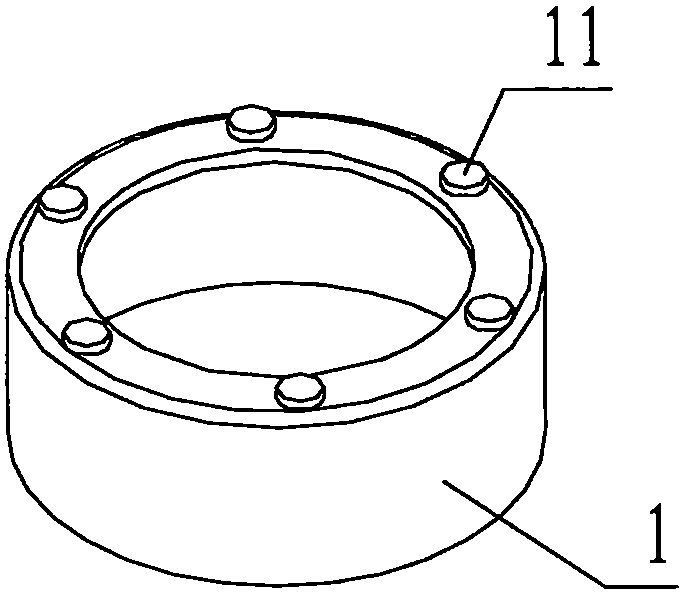

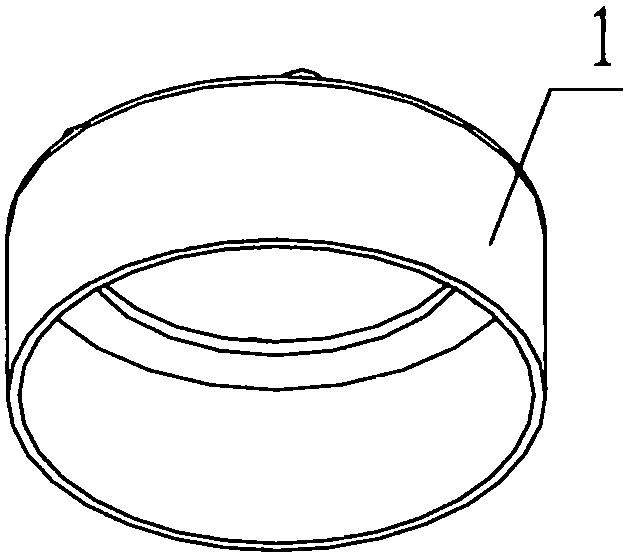

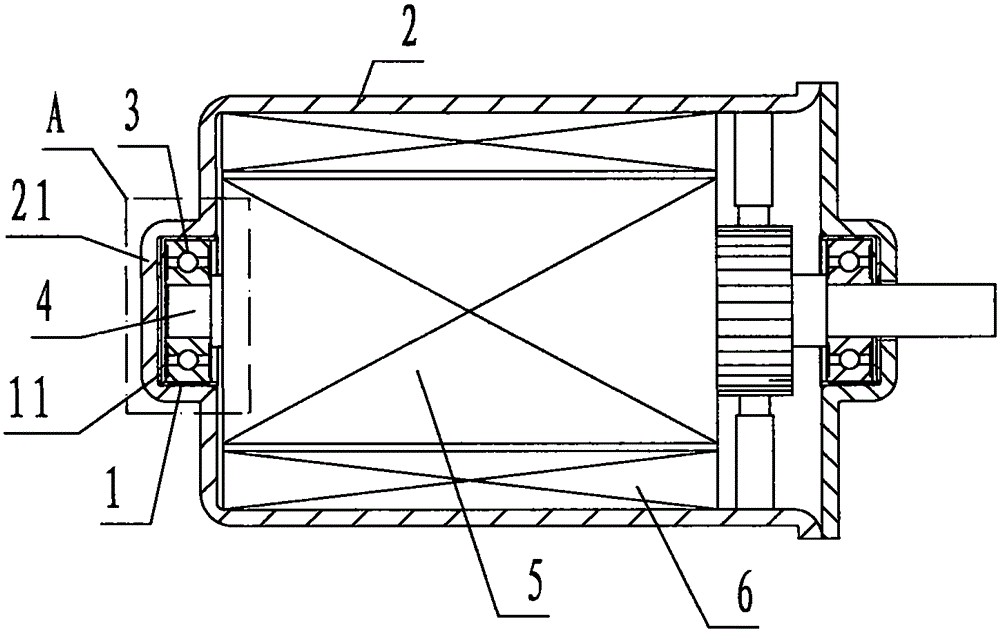

[0017] refer to Figure 1 ~ Figure 4 , a bushing for a rotor bearing of an automobile power steering motor according to the present invention, the bushing 1 is an annular thin-walled ethylene-propylene rubber member, and the upper end surface of the bushing 1 is evenly provided with several cylindrical flanges called male end 11;

[0018] In application, the rotor shaft is statically fitted with the inner ring of the rotor bearing 3, the bushing 1 is set on the outer ring of the rotor bearing 3, and the bushing 1 and the rotor bearing 3 are jointly placed in the inner cavity of the bearing seat 21 of the stator shell 2 , the convex end 11 is in contact with the axial end surface of the inner cavity of the bearing seat 21 .

[0019] Working Principle and Beneficial Effect

[0020] Through the elastic liner of the bushing 1, the axis of the rotor 5 and the axis of the inner bore of the stator magnet 6 can be flexibly corrected and tend to be coaxial, and the rigid contact betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com