Instant-plug spherical hinge-type quantifiable-yield steel arch connecting component and using method

A technology for connecting components and steel arches, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of complicated installation procedures of steel arches, difficult to evaluate the supporting effect, and low working efficiency of workers, and achieves convenient evaluation. The effect of supporting effect, simplifying the assembly process, and monitoring the work is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

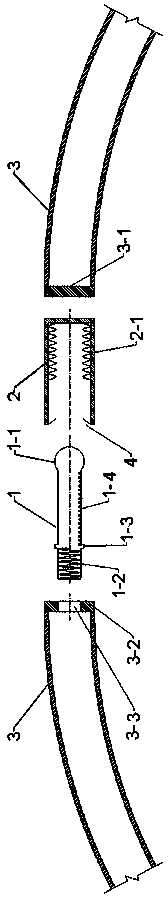

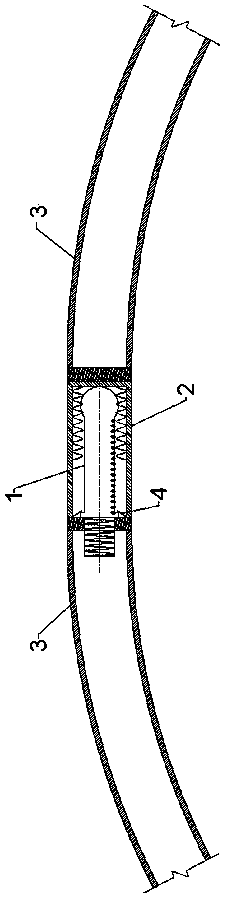

[0030] Embodiment 1: A plug-in spherical joint type steel arch connection member with quantifiable yielding pressure, see Figure 1-Figure 3 , including two symmetrically arranged steel arches 3, the connecting member is arranged between the two steel arches; the connecting member includes a connecting rod 1 and a sleeve 2, the connecting rod 1 includes a spherical end 1-1 at one end, and the other The threaded end 1-2 at one end and the rod body in the middle are provided with an annular protrusion 1-3 at the connection between the threaded end 1-2 and the rod body, and a scale line 1-3 is provided on the outer surface of the rod 1 of the connecting rod 1. 4.

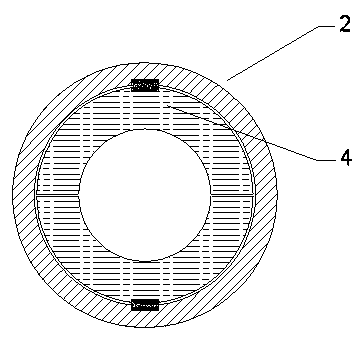

[0031] The casing 2 is a cylindrical structure with one end closed and the other open. An internal thread 2-1 is provided on the inner wall of the casing 2 close to the closed end, and a one-way snap is provided on the inner wall of the open end of the casing 2. part 4, one end of the one-way engaging part 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com