Technical method for checking corrugated plate tightness of hydro-generator stator

A technology of a hydro-generator and a process method, which is applied in the manufacture of motor-generators, electrical components, electromechanical devices, etc., can solve the problems of large vibration of the unit, easy loosening of slot wedges, and inability to detect comprehensively, so as to improve installation efficiency and improve The effect of measuring accuracy and saving installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

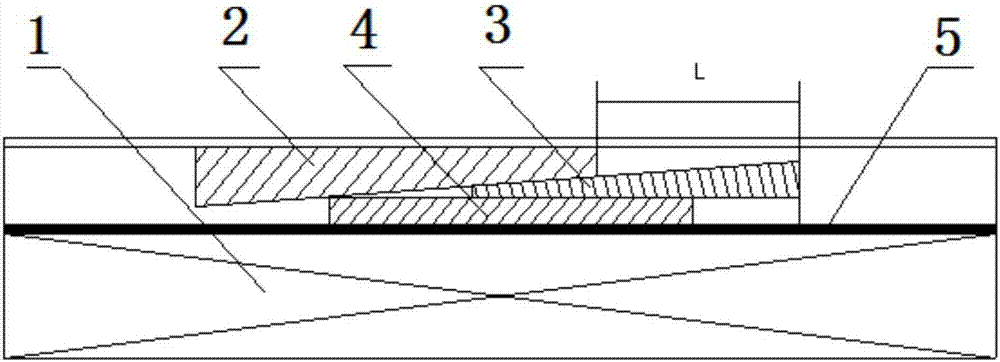

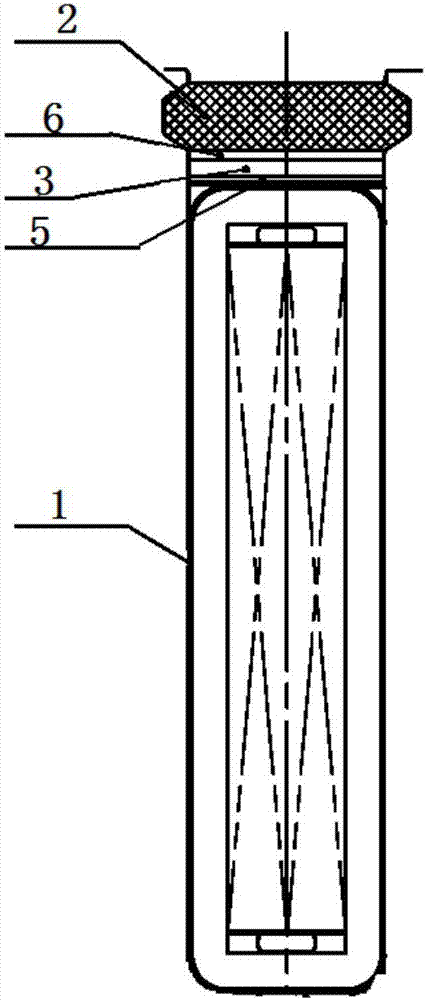

[0008] Such as figure 1 A method for inspecting the tightness of the stator corrugated plate of a hydroelectric generator is shown, which consists of a stator corrugated plate tightness measuring device composed of stator wire rods, main slot wedges, auxiliary slot wedges, a corrugated plate tightness inspection sample, and pad strips under the wedges , place multiple under-wedge pads on the straight section of the stator bar, put the main slot wedge, auxiliary slot wedge and the corrugated plate tightness inspection sample into the stator bar together, and the auxiliary slot wedges are placed on the corrugated plate tightness inspection sample and Between the main slot wedges, tighten the auxiliary slot wedges with the main slot wedges with a slot wedge tool, measure and control the exposed length of the auxiliary slot wedges L=100~125mm, measure the actual thickness of the pad under the wedges, at this time the slot wedges The thickness of the lower pad meets the installatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com