EHV diaphragm compressor hydraulic leading seal diaphragm head

A diaphragm compressor and guided technology, which is applied in the direction of mechanical equipment, variable capacity pump components, machines/engines, etc., can solve the problems of space occupation, inability to arrange, and large fastening force, etc., to reduce space occupation and save Space and materials, the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

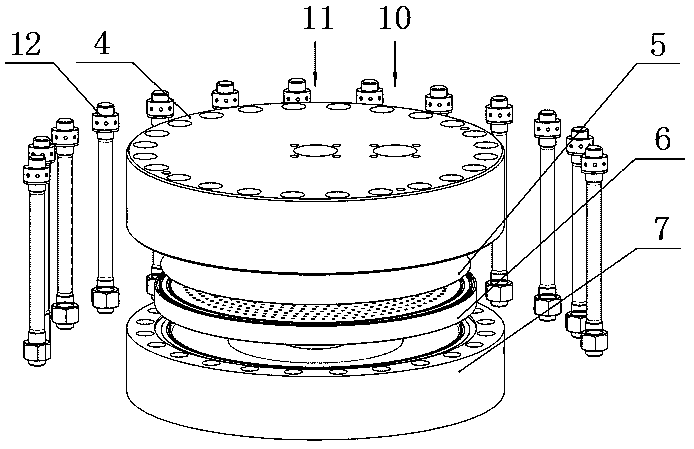

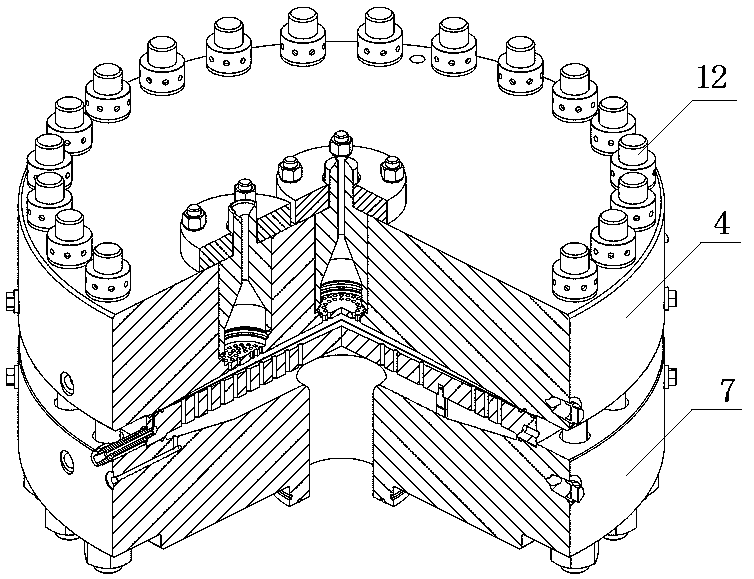

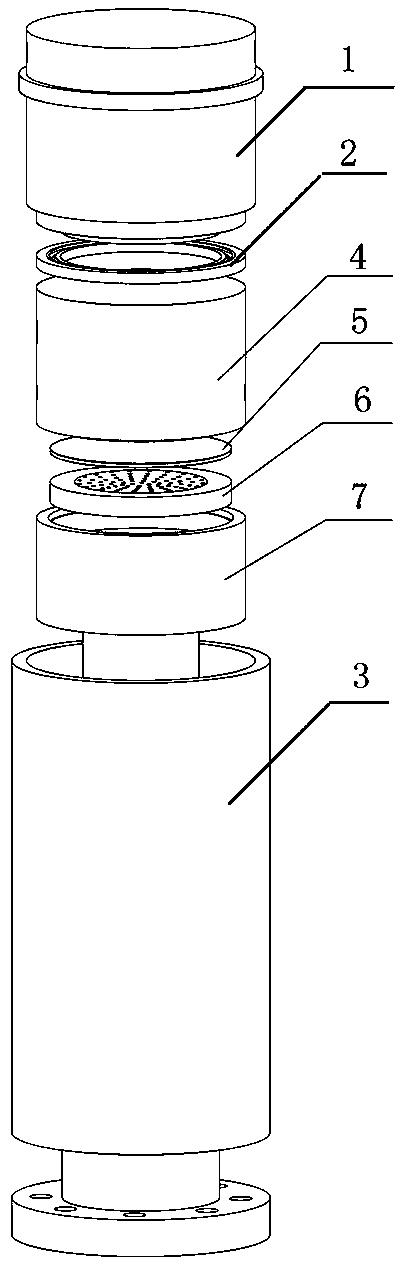

[0026] Such as figure 1 -6 shows the hydraulically guided sealing diaphragm head of the ultra-high pressure diaphragm compressor of the present invention, including the cylinder head 4, the diaphragm 5, the oil distribution plate 6 and the cylinder body 7. The structures and functions of the above components are basically the same as those of the existing ones; It includes a stuffing box 3 for accommodating the above-mentioned parts and a main nut 1 for fastening the parts in the box matched with the stuffing box; in the stuffing box from top to bottom are cylinder head, diaphragm, oil distribution plate and Cylinder body, the cylinder body is in an inverted "convex" shape, which cooperates with the limit table at the lower part of the stuffing box to play the role of limit position; the upper part of the cylinder body is provided with a groove for accommodating the oil distribution plate and the diaphragm, The groove plays the role of accommodating the above-mentioned compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com