Multi-radian special steel reticulated shell structure manufacture method

A manufacturing method and technology of steel reticulated shell, applied in the direction of arch structure, dome roof structure, building components, etc., can solve the problems such as failure to achieve CNC milling tempered glass without gaps, failure to meet project quality requirements, and low installation efficiency. , to achieve the effect of fast production, good simmering effect and low installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

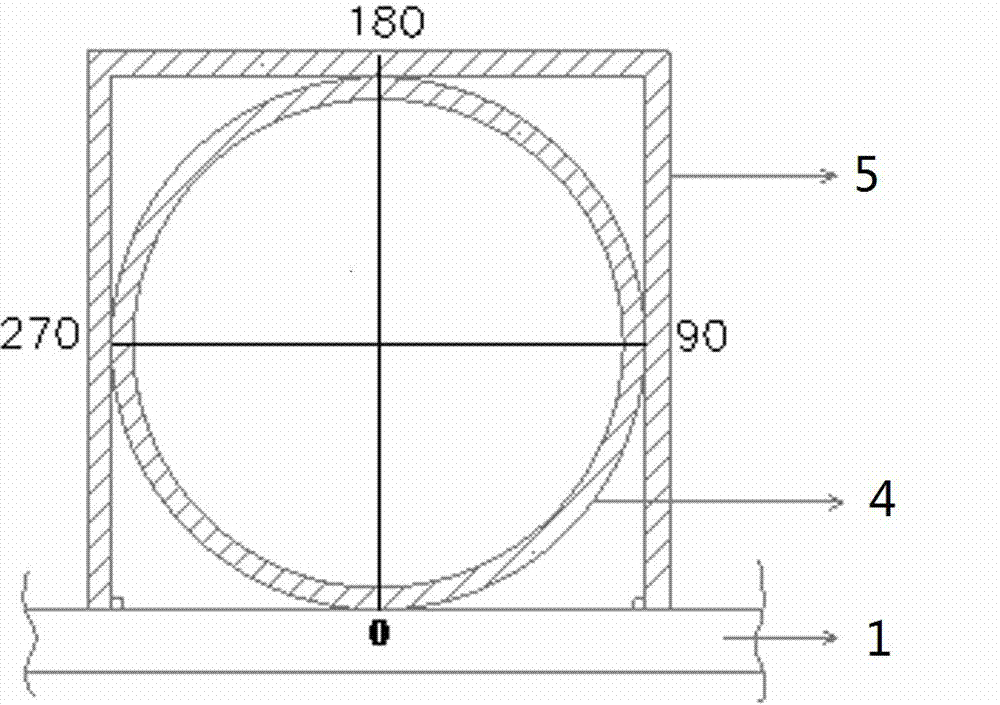

[0022] see Figure 1-Figure 6 , a method for manufacturing a multi-radian space steel reticulated shell structure, comprising the steps of:

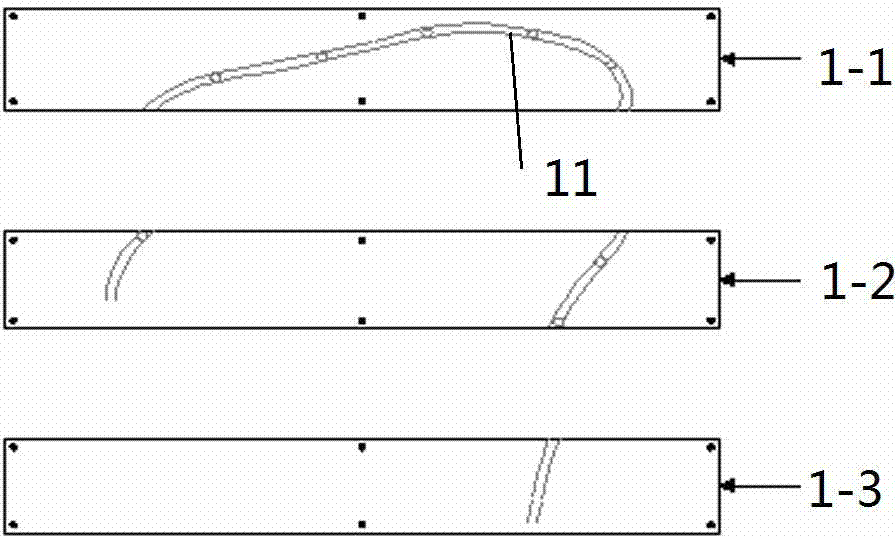

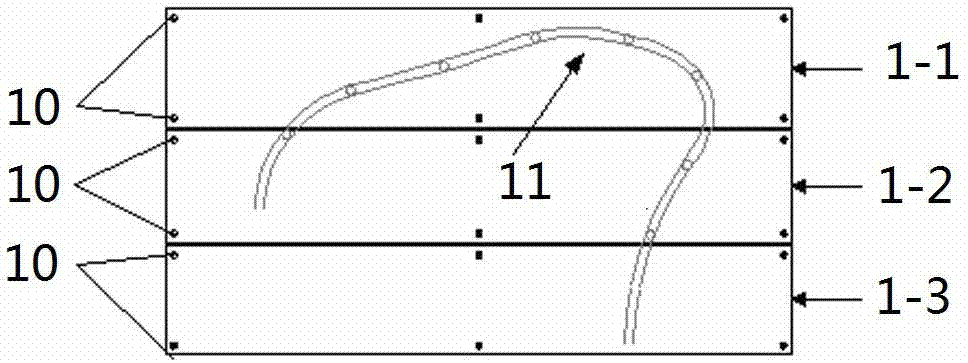

[0023] Step 1. Use a hydraulic bending machine to bend the steel pipe to make a multi-arc bend 4;

[0024] Step 2. Fabrication of the model of the multi-arc bend pipe (model steel plate 1)

[0025] Use the spray powder of the CNC cutting machine to paint the stakeout line of the 1:1 multi-arc bend pipe on the steel plate (the rendering of the multi-arc bend pipe), and complete the production of the model of the multi-arc bend pipe; according to the multi-arc bend pipe The length and width of the steel plate determine the size of the steel plate. In this embodiment, three steel plates (the first steel plate 1-1, the second steel plate 1-2, and the third steel plate 1-3) are used for lofting and splicing. First, the three steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com