Novel non-metal expansion joint

A non-metallic expansion joint technology, applied in expansion compensation devices for pipelines, adjustable connections, pipes/pipe joints/fittings, etc., can solve problems such as poor flexibility and easy damage, and achieve convenient pipeline design. Strong adaptability and good vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

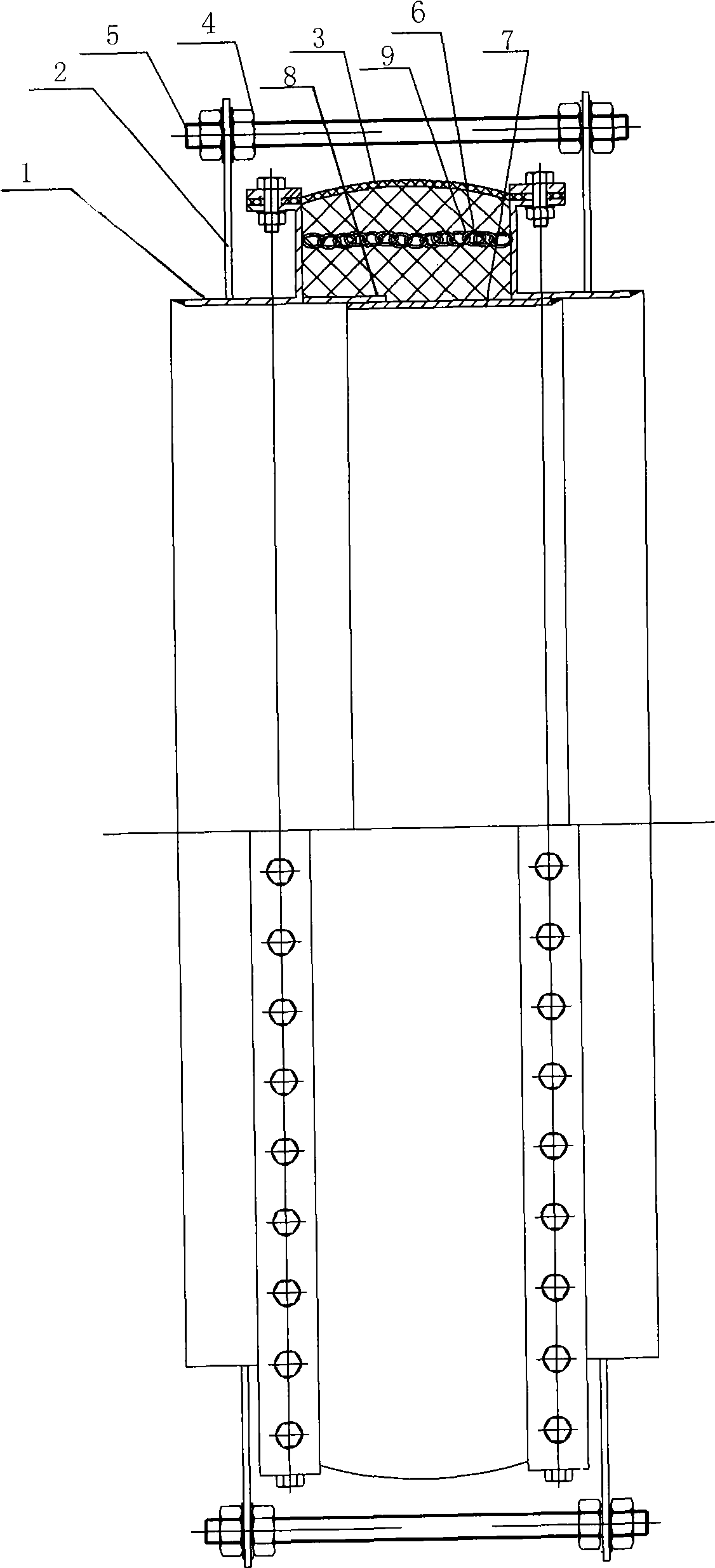

[0007] This specific embodiment adopts the following technical solutions: it is composed of a connecting pipe 1, an ear plate 2, a flexible ring belt 3, a nut 4, a stud 5, a high-aluminum brazing fiber cotton 6, a guide tube 7, an inner guide tube 8 and a hinge 9 components; the connecting pipe 1 is arranged at the bottom end of the lug plate 2, and the two are vertically connected, a high-aluminum brazing fiber cotton 6 is arranged under the flexible ring belt 3, and a hinge 9 is arranged on the high-aluminum brazing fiber cotton 6, The stud 5 is arranged on one side of the nut 4, and the guide tube 7 is arranged under the inner guide tube 8; the surface layer of the hinge 9 is made of stainless steel wire mesh, and the inner layer is made of silicon rubber cloth, reinforced fiber cloth, four Composed of fluorocloth, glass fiber cloth, and composite tianjin cloth, it has good flexibility and has a reverse thrust effect on equipment and systems, which brings convenience to pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com