Guide cylinder structure applied on corrugated pipe expansion joint

A technology of guide tube and expansion joint, which is applied in the direction of expansion compensation device for pipelines, pipe components, pipes/pipe joints/fittings, etc., which can solve the problems of reducing the service life of bellows, increasing the service temperature of bellows, and using guide tubes. To avoid problems such as distortion and deformation, achieve the effect of reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

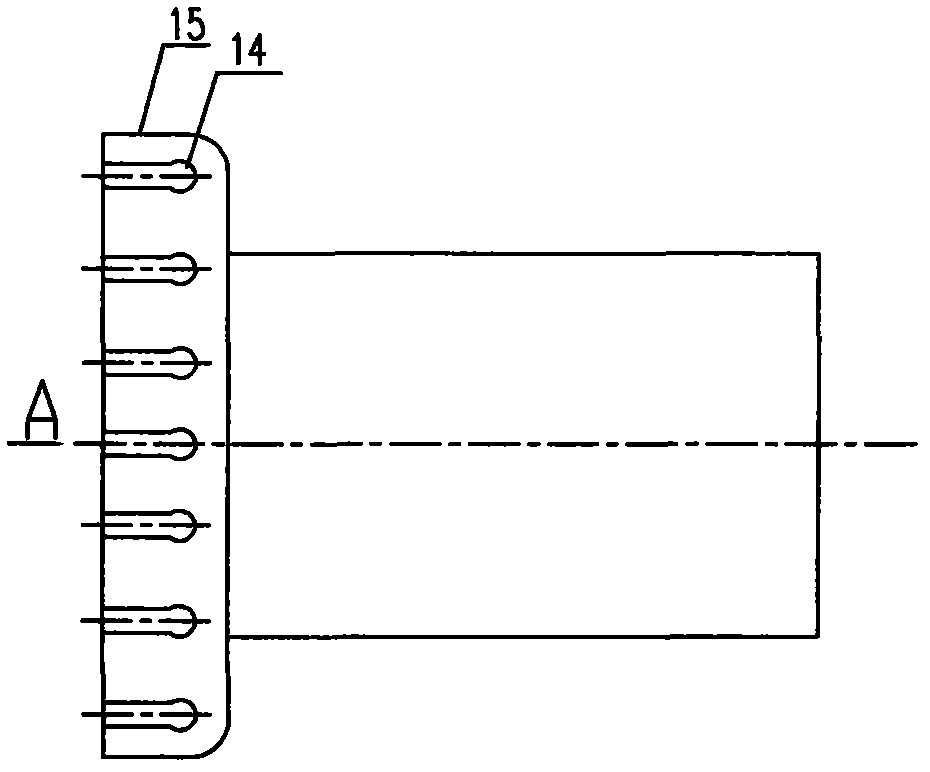

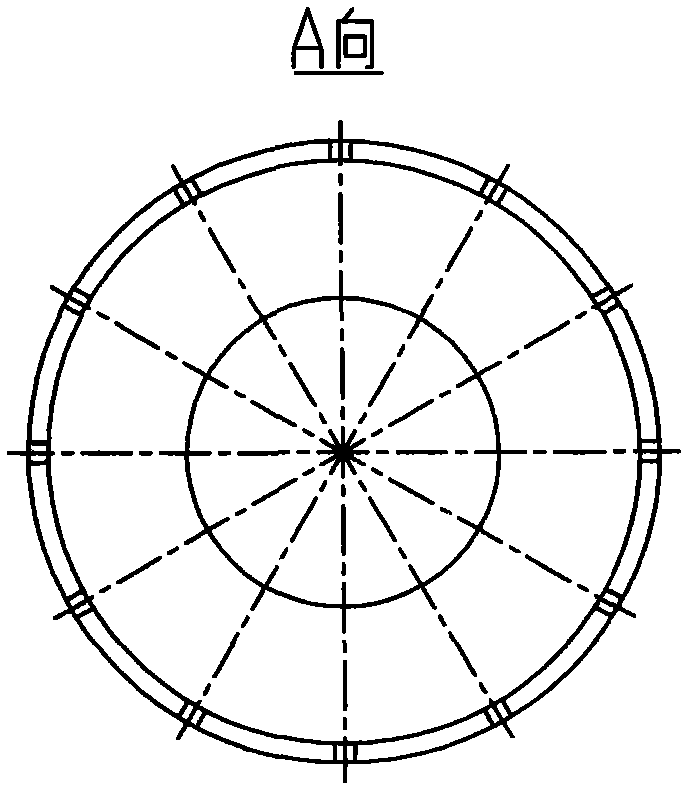

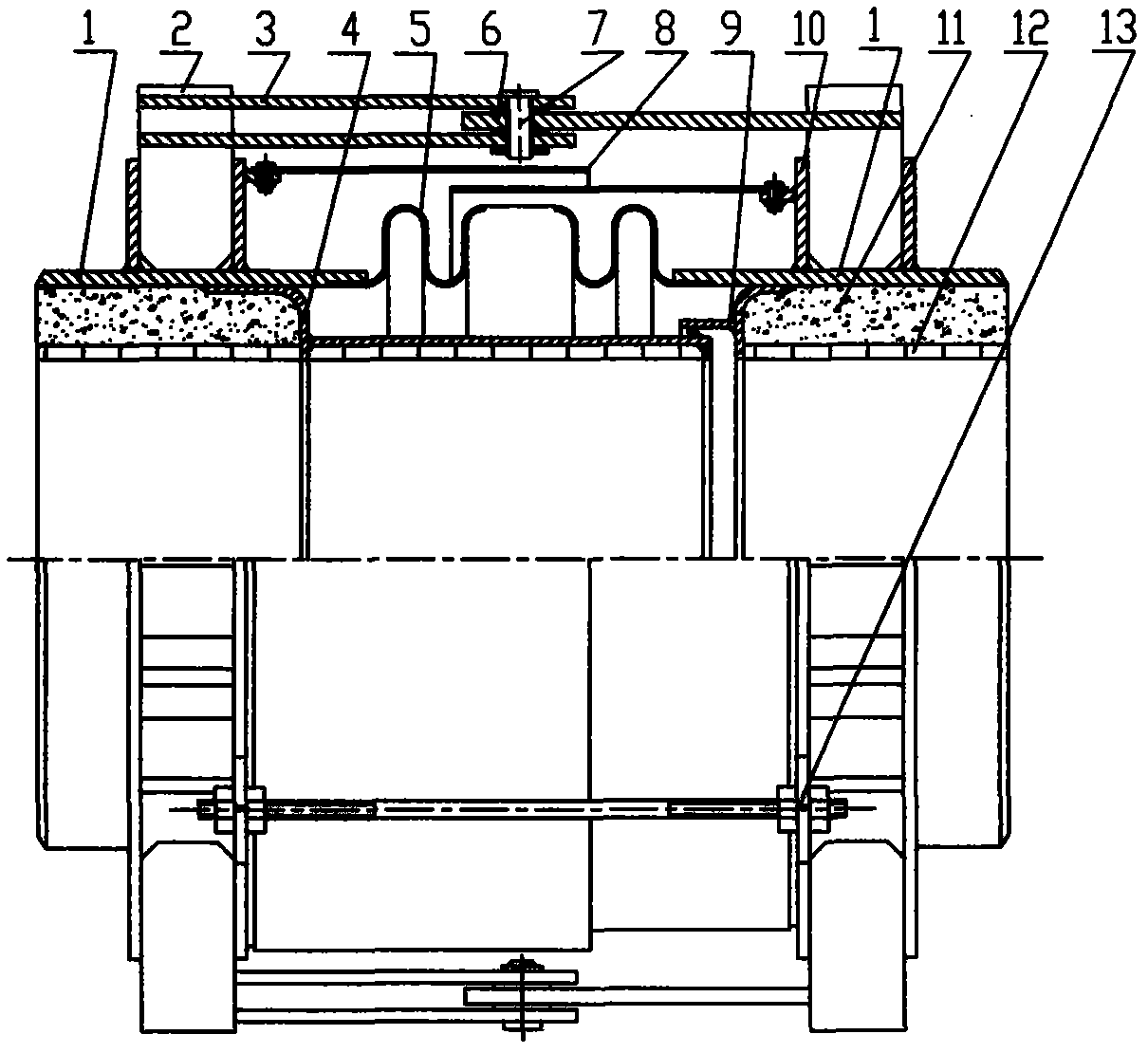

[0012] like figure 1 shown, combined with figure 2 , a guide tube structure applied to bellows expansion joints, the front end of the guide tube is a guide tube compensation ring 15 with a circular arc transition, and the outer surface of the guide tube compensation ring 15 is set There are 12 stress relief grooves 14 distributed along the circumference of the cylinder. The stress relief grooves 14 are consistent with the axial direction of the guide cylinder. The stress relief grooves 14 reduce the hoop stress generated by the guide cylinder due to thermal expansion, so that the flow guide The tubes 4 and 9 are not twisted and deformed; the arc section of the guide tube compensating ring of the guide tube is attached to the tube section of the bellows expansion joint, and the front end of the arc section is welded to the tube section of the expansion joint. When the guide tube is heated and expanded, the arc-shaped transition section absorbs the radial displacement and axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com