Closing structure for expansion joint reserved in wall surface or roof surface

A technology of expansion joints and top surfaces, which is applied in the direction of building construction and construction, can solve the problems of inconsistent size of contraction joints, and achieve the effects of convenient construction, firm structure and simple positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

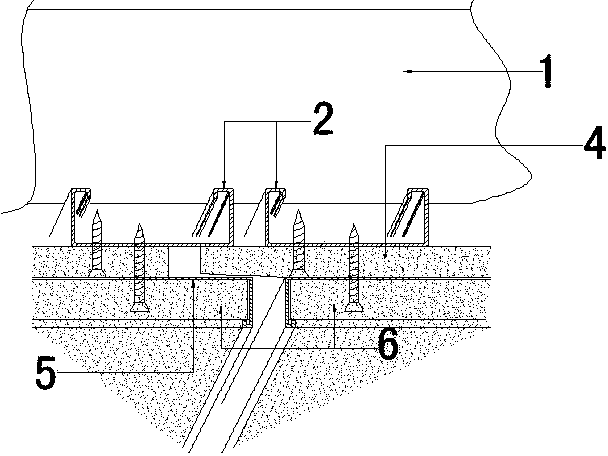

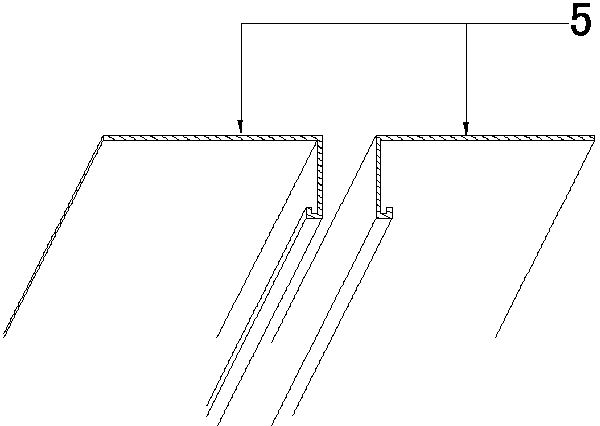

[0020] Example: such as figure 1 Shown: a closing structure with expansion joints on the wall and top surface, which includes a main keel 1, an auxiliary keel 2, self-tapping screws 3, closing strips 5, a first layer of gypsum board 4, and a second layer of gypsum board 6. Gypsum board is paper-faced gypsum board. Pay keel 2 for model 50.

[0021] Determine the size of the base layer according to the design requirements and install the main keel 1 according to the conventional process. The width of the connection seam between the auxiliary keels 2 is 10mm: a 10mm space is left between the two auxiliary keels 2 for balanced installation. The auxiliary keel 2 is fixed with the main keel 1. The two closing strips 5 are balanced and fixed under the first layer of plasterboard 4, leaving a space of 10mm in the middle; the second layer of plasterboard 6 is installed by leaving a 5mm seam on the aluminum edge of the closing strip 5, and fixing it with self-tapping screws 3 after a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com