Water-cooled nonmetal expansion joint

A non-metallic expansion joint technology, applied in expansion compensation devices for pipelines, pipeline heating/cooling, pipes/pipe joints/fittings, etc., can solve the problem of short service life and inability to effectively absorb the three-way displacement of furnace smoke pipes , wear-resistant materials and heat insulation sleeves are easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

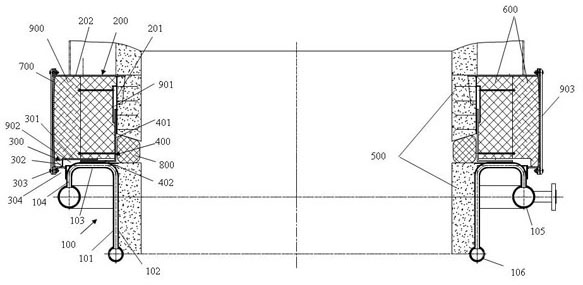

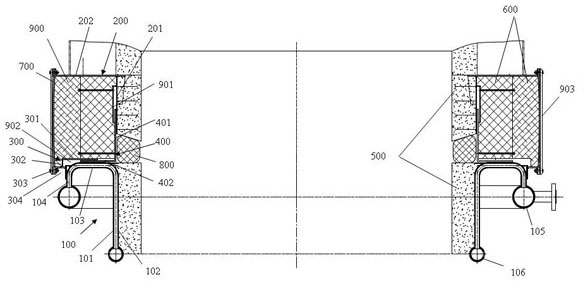

[0020] Such as figure 1 As shown, the water-cooled non-metallic expansion joint of the present invention includes a water-cooled wall 100, an upper metal frame 200, a lower metal frame 300, a movable metal frame 400, two-stage castables 500, a thermal insulation sleeve 600, a telescopic sleeve 700 and a dustproof Circle 800.

[0021] Wherein the water wall 100 is bent into " ”-shaped carbon steel small-diameter seamless steel pipe 101 is surrounded, and the carbon steel small-diameter seamless steel pipe 101 is welded through ribs, so that the water-cooled wall 100 has a first cylindrical wall 102 and is located outside the upper end of the first cylindrical wall 102 The first annular end plate 103 and the annular outer wall 104 outside the annular end plate, and the two ends of the water wall 100, that is, the lower end of the first cylindrical wall 102 and the lower end of the annular outer wall 104 are connected with each carbon Ring-shaped water collection tanks 105 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com