Volume compensation device for expansion joint of double-layer corrugated pipe

A double-layer bellows, volume compensation technology, applied to expansion compensation devices, pipe components, pipes/pipe joints/fittings for pipelines, etc., can solve double-layer bellows leakage, vacuum system leakage sensitivity, pressure value change Larger problems such as avoiding misjudgment and reliable monitoring device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in conjunction with accompanying drawing and specific embodiment:

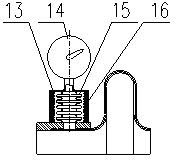

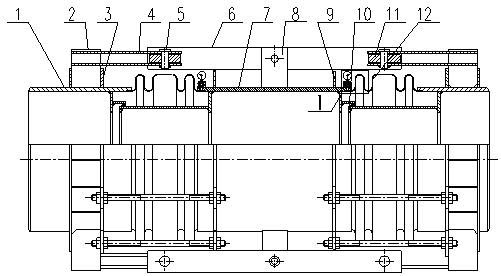

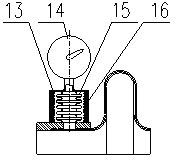

[0012] Such as figure 1 As shown, a volume compensating device used on a double-layer bellows expansion joint mainly includes a volume compensating bellows 15 and a driving spring 16; The upper end is welded on the sealing plate 13, and is connected with the vacuum pressure gauge 14 through the through hole on the sealing plate 13, and the vacuum pressure gauge is connected with the volume compensation bellows to monitor the pressure change of the vacuum system; the volume compensation bellows 15 The lower end is welded on the end pipe 1, and communicates with the interlayer of the straight pipe section of the double-layer bellows through the through hole on the end pipe 1, so that the interlayer of the volume compensation bellows and the double-layer bellows is connected; it is used to drive There are two drive springs 16 that provide volume compensation when the vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com