Resin bus expansion joint

An expansion joint and resin technology, applied in the direction of fully enclosed busbar devices, insulators, etc., can solve the problems that the insulating film layer is not waterproof, the structure is not compact enough, and the size of the expansion joint is large, so as to achieve high protection level, compact structure, and save installation space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

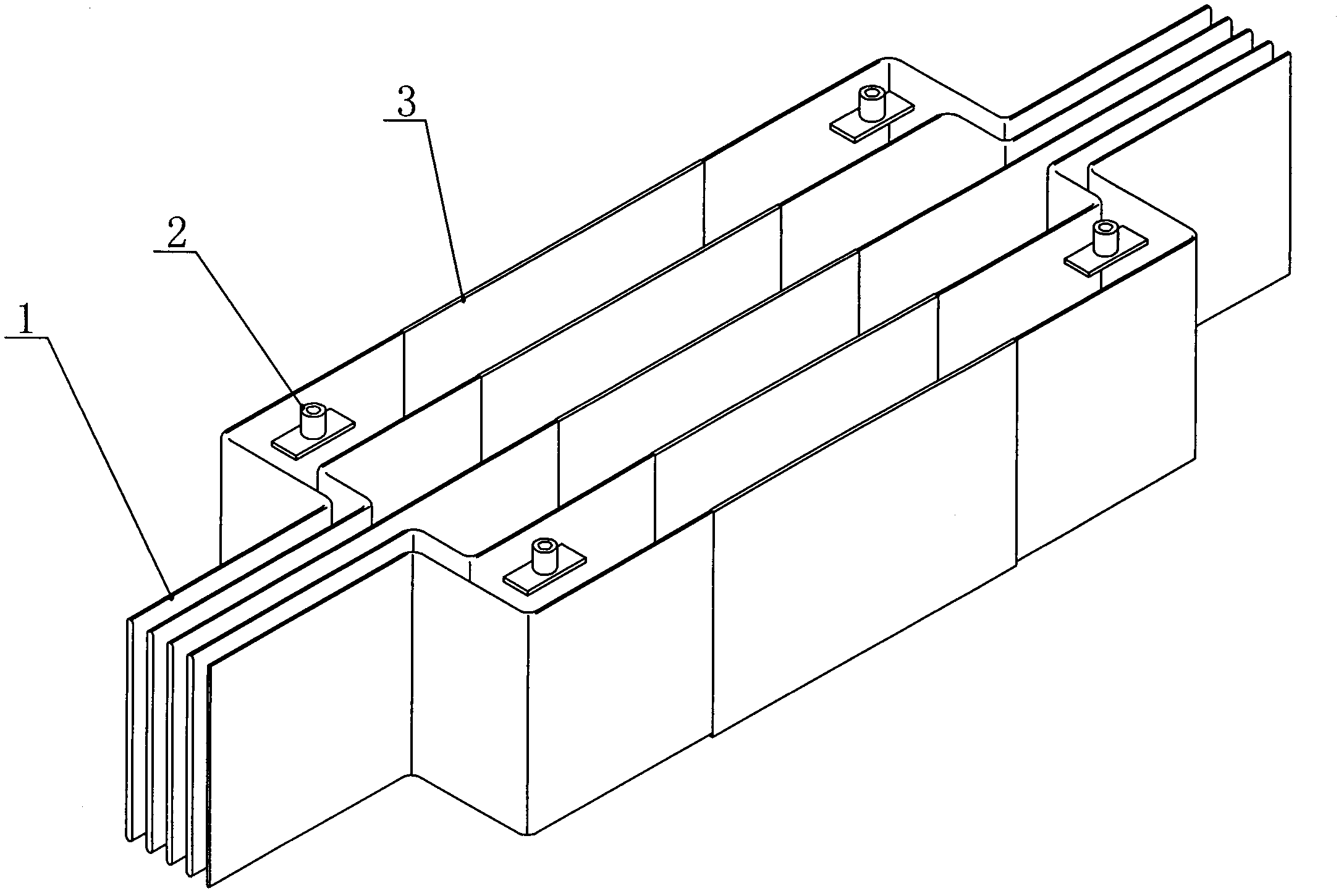

[0017] figure 1 It is a diagram of the conductor combination before the pouring of the resin bus expansion joint of the present invention. There are corresponding multiple hard conductors 1 at both ends, and the hard conductors 1 are connected one by one by the flexible metal conductor 3 located in the middle. The flexible metal conductor 3 is preferably composed of multiple Thin strip-shaped metal conductors are stacked layer by layer, and the two ends of the flexible metal conductor 3 are welded to the hard conductor 1 respectively.

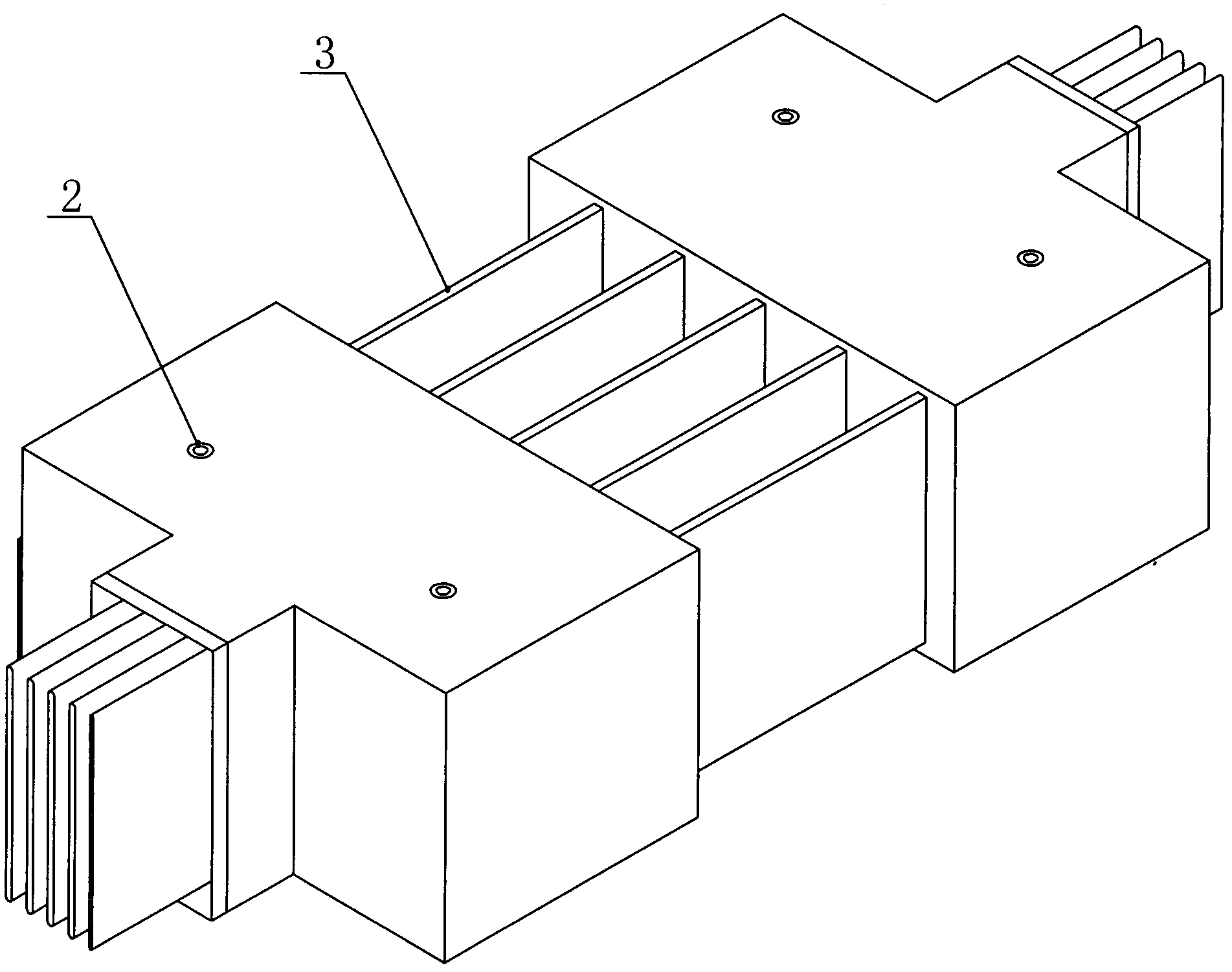

[0018] figure 2 It is the structure diagram after pouring. Each rigid conductor 1 is wrapped by a resin insulator and the rigid conductors 1 are separated by a resin insulator.

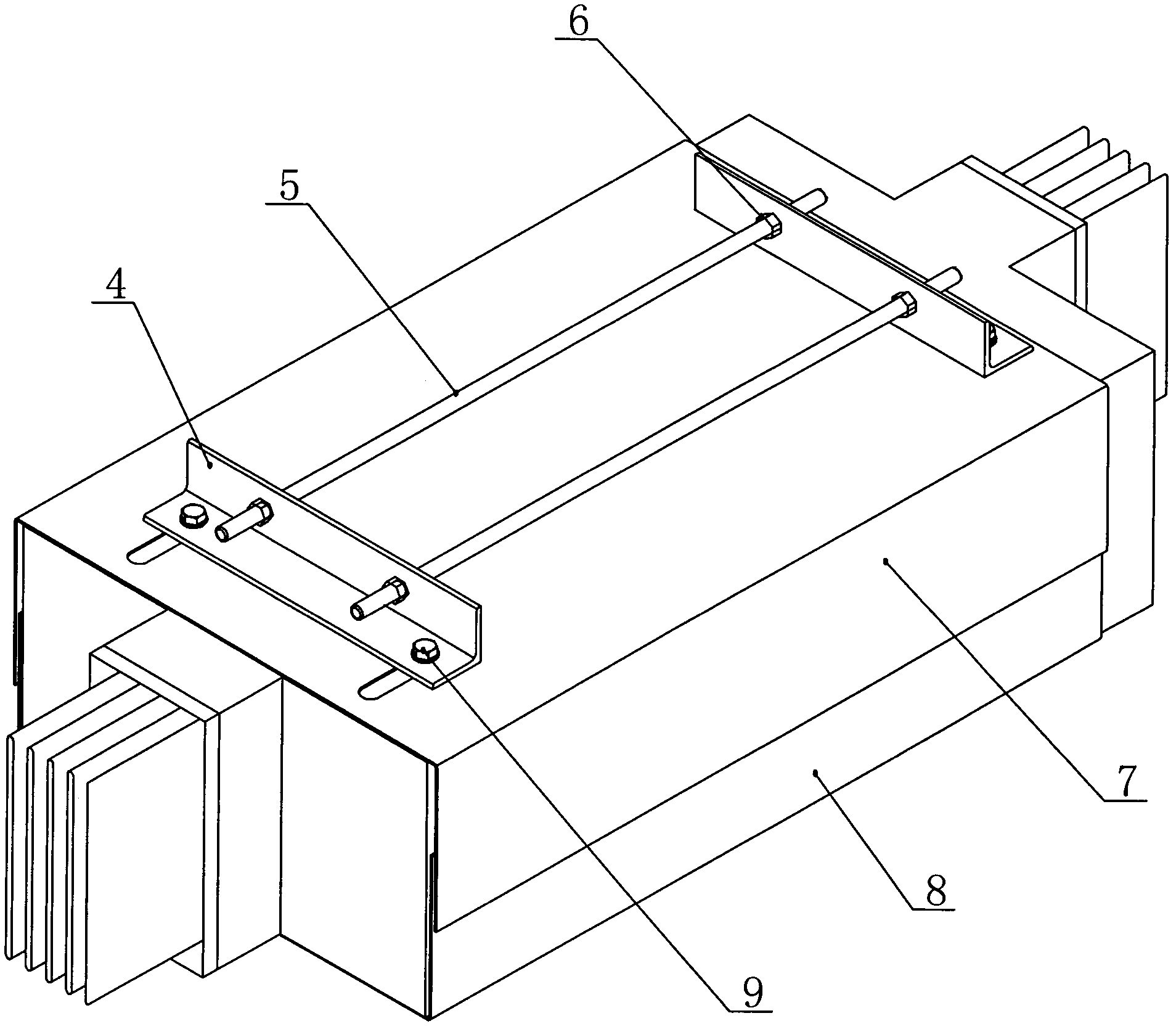

[0019] Such as Figure 4 As shown, the outer periphery of each flexible metal conductor 3 is respectively wound with an insulating film 3a, and the outer periphery of each insulating film 3a is respectively covered with a heat-shrinkable sleeve 3b.

[0020] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com