Floor expansion joint structure used in complex use environments and construction method thereof

A technology of expansion joints and floors, which is applied to building structures, building components, floors, etc., can solve the problems of prone to staggered platforms, unprotected board edges, and damaged experimental facilities, etc., to achieve convenient construction, waterproof and durable even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

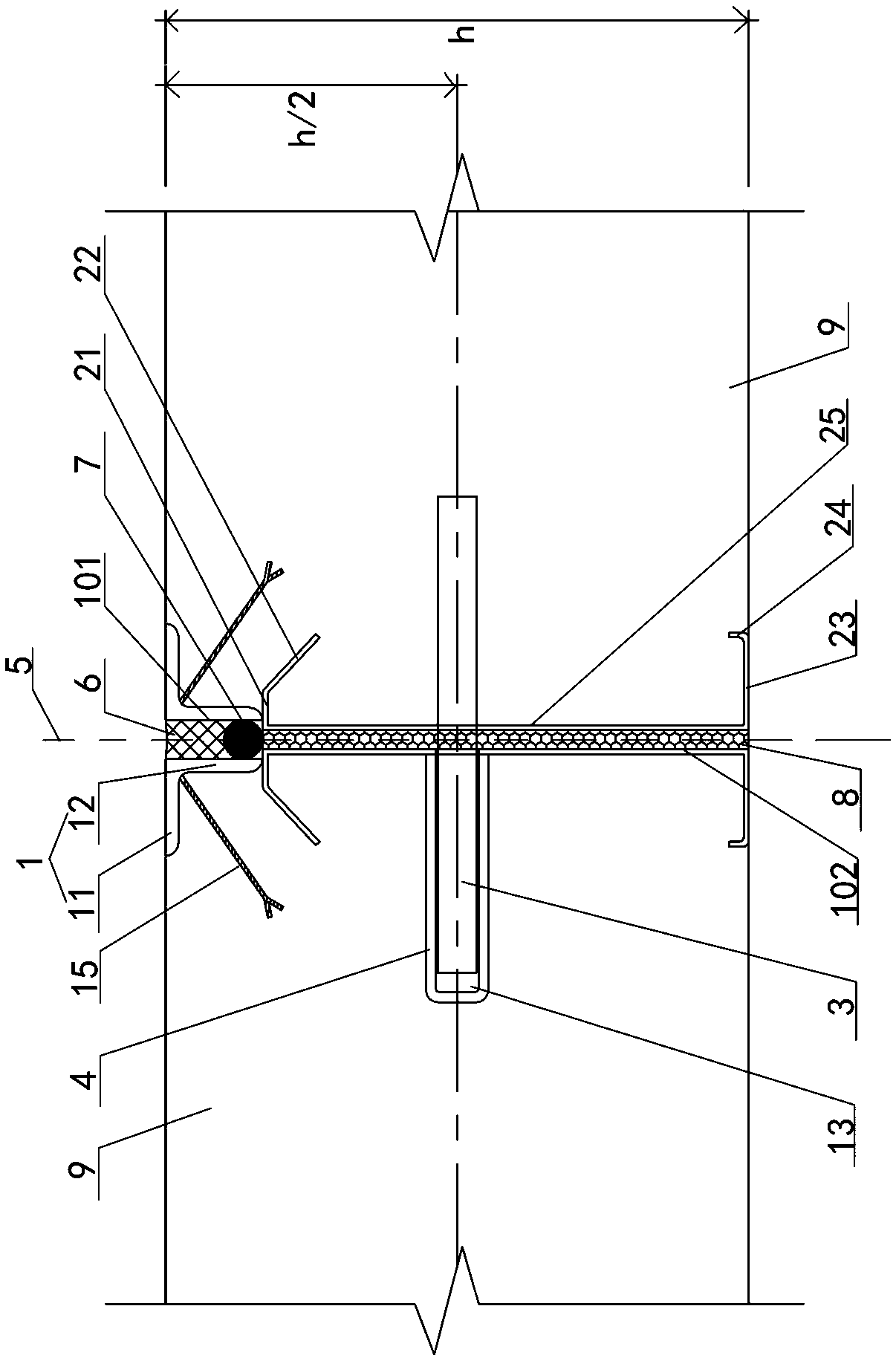

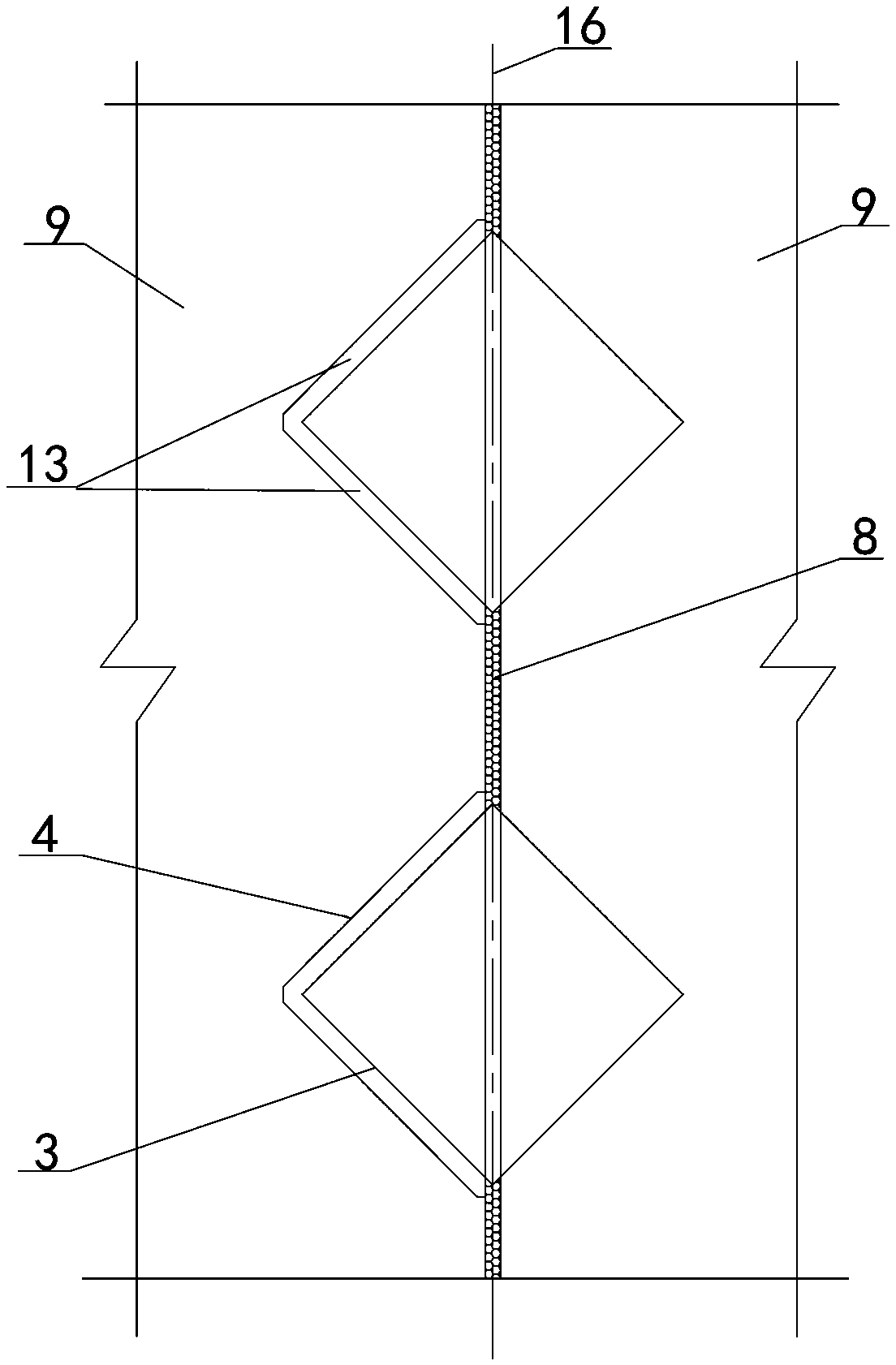

[0040] Examples see Figure 1-3 As shown, a floor expansion joint structure used in a complex use environment includes the floor 9 on both sides and the expansion joint 10 formed between the side end surfaces of the floor.

[0041] The floor expansion joint structure also includes a floor edge-sealing steel structure, an edge-sealing limit structure, an expansion joint waterproof structure, and an expansion joint force transmission structure.

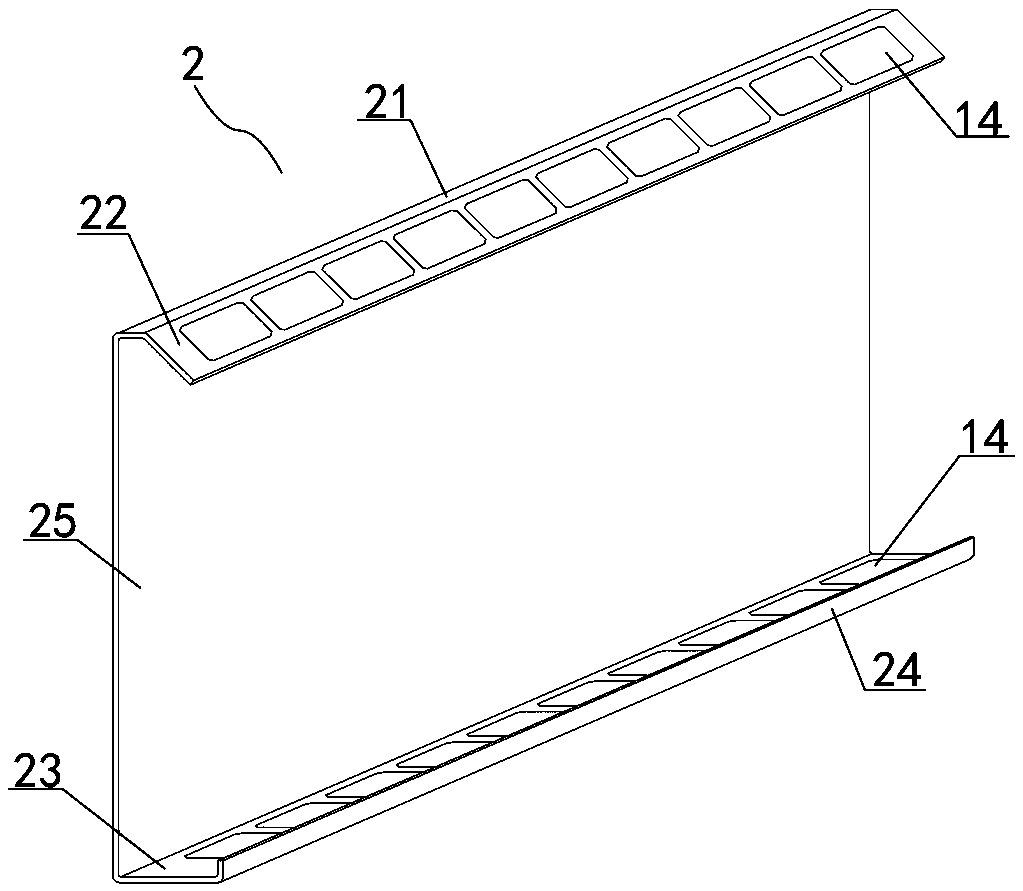

[0042] The floor edge-sealing steel structure is arranged symmetrically along the length direction of the expansion joint, and the floor edge-sealing steel structure is vertically outsourced on the side end faces of the two sides of the floor, including the upper closed angle steel 1 and the lower edge-sealing thin wall Section steel 2.

[0043] The closed angle steel 1 includes a horizontal leg 11 and a vertical leg 12, the upper side of the horizontal leg 11 is flush with the upper side of the ground 9, and the outer side of the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com