Device and method for online leakage monitoring of double-layer metal expansion joint

A double-layer metal and monitoring device technology, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/fittings, pipeline systems, etc., can solve the problem that the monitoring solution cannot be monitored online, so as to ensure online safety and guarantee Effects of safe operation and leakage avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

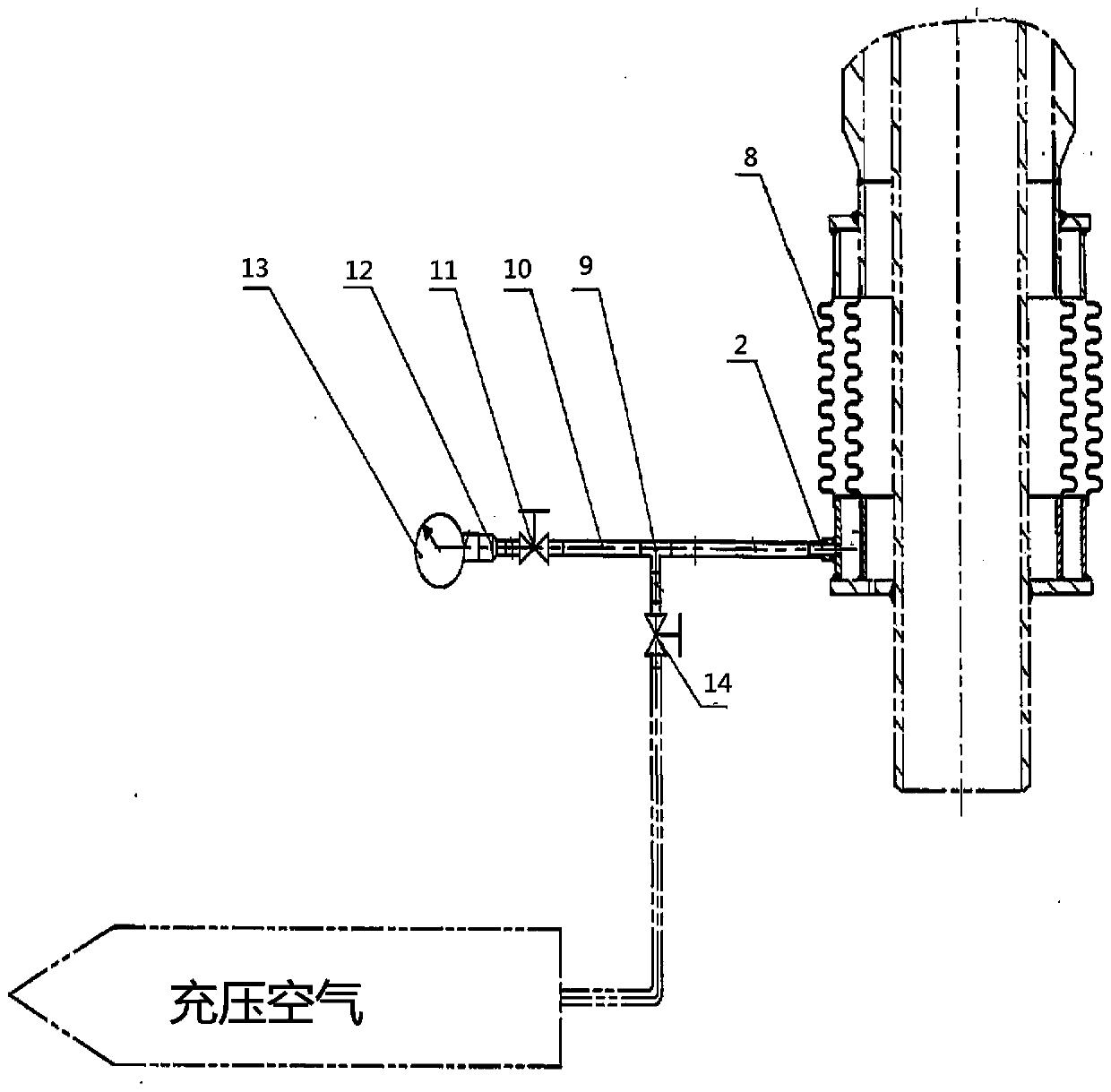

[0044] Such as image 3 An online leakage monitoring device for a double-layer metal expansion joint is shown, which is used to monitor the damage of the double-layer metal expansion joint 8, including an equal-diameter tee joint 9, a pressure pipe 10, a valve A11, a pressure gauge joint 12, and a pressure gauge 13. Valve B14.

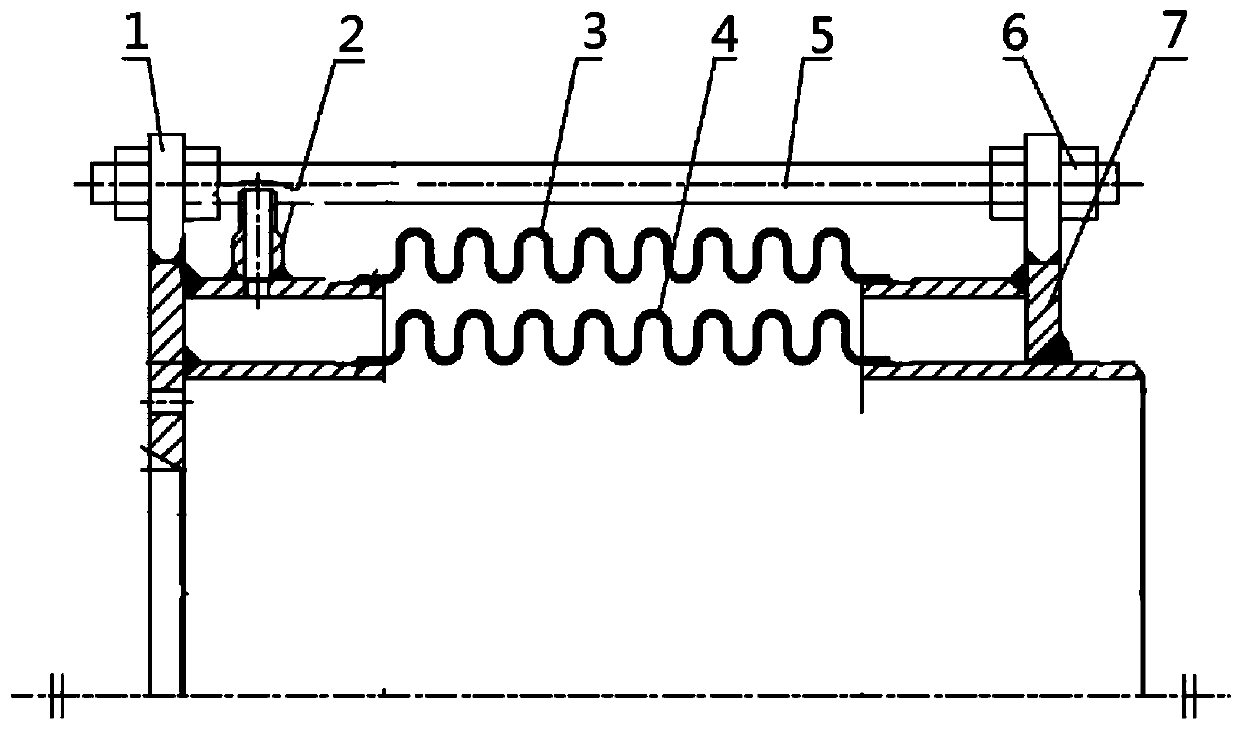

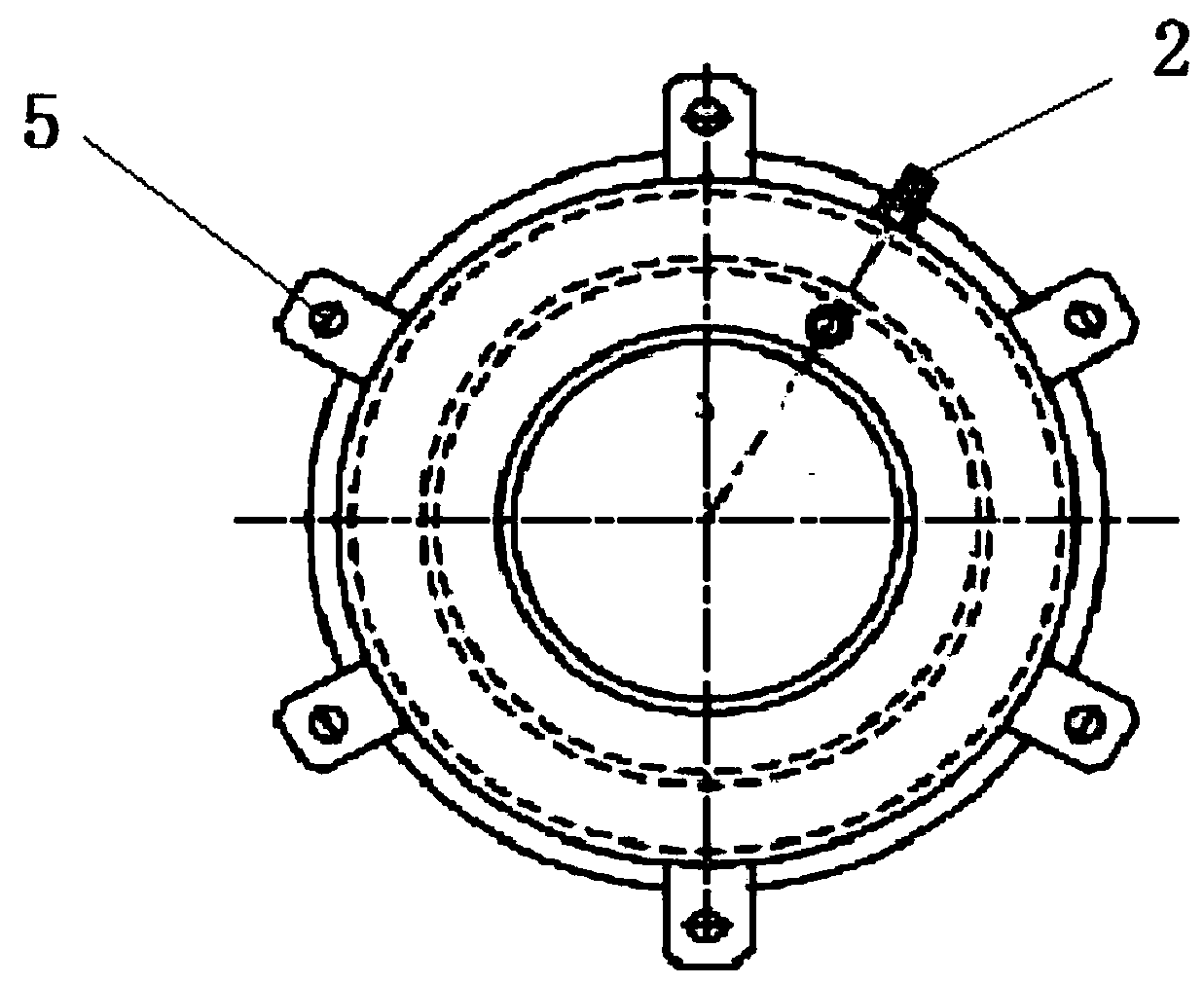

[0045] Such as figure 1 , figure 2 As shown, the double-layer metal expansion joint 8 is divided into an outer layer 3 and an inner layer 4, and the outer layer 3 and the inner layer 4 are both bellows structures, which serve as the boundary of the pressure pipe and are used for the thermal expansion and contraction of the pipe. Axial compensation effect.

[0046] The double-layer metal expansion joint 8 is arranged vertically along the axial direction, the ear plate 1 is located at the lower part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com