Universal angle hinge type expansion joint

A technology of expansion joints and hinges, which is applied in the field of expansion joints, can solve the problems of not being able to make axial or angular compensation at the same time, and reduce performance, so as to improve work reliability and usability, prolong service life, and reduce manufacturing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

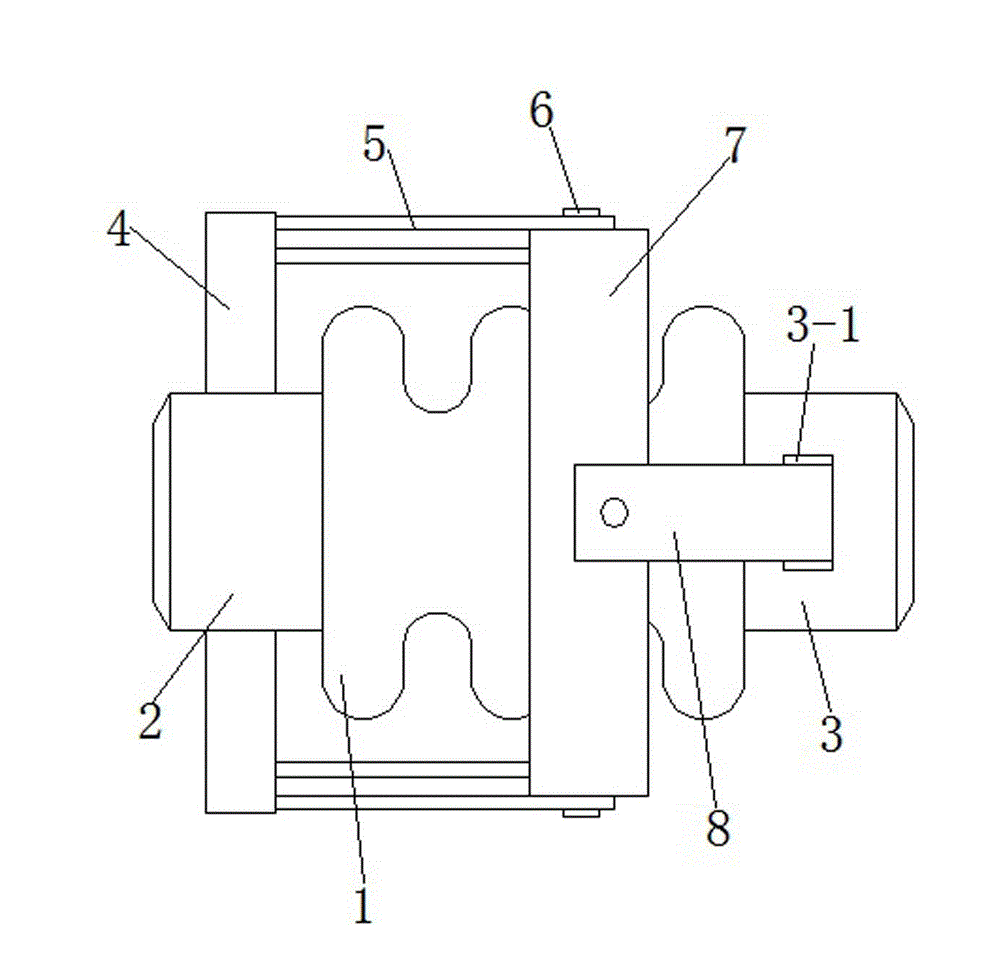

[0010] Such as figure 1 As shown, the universal angle hinge type expansion joint includes a bellows 1, a left connecting pipe 2 and a right connecting pipe 3 arranged at the left and right ends of the bellows 1, and a pin assembly, and the pin assembly includes a vertical plate 4, a hinge plate 5. The pin shaft 6 and the universal ring 7, the vertical plate 4 is fixed on the left connecting pipe 2 by screws, the universal ring 7 is fixed on the bellows 1 by screws, the vertical plate 4 and the universal ring 7 are fixedly connected by the hinge plate 5, and the hinge plate 5 is arranged on both sides of the bellows 1, and the hinge plate 5 is fixed with the universal ring 7 by the pin shaft 6, The slider 8 connects the universal ring 7 and the right connecting pipe 3; in this embodiment, when the pipeline is expanded or compressed, the universal ring driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com