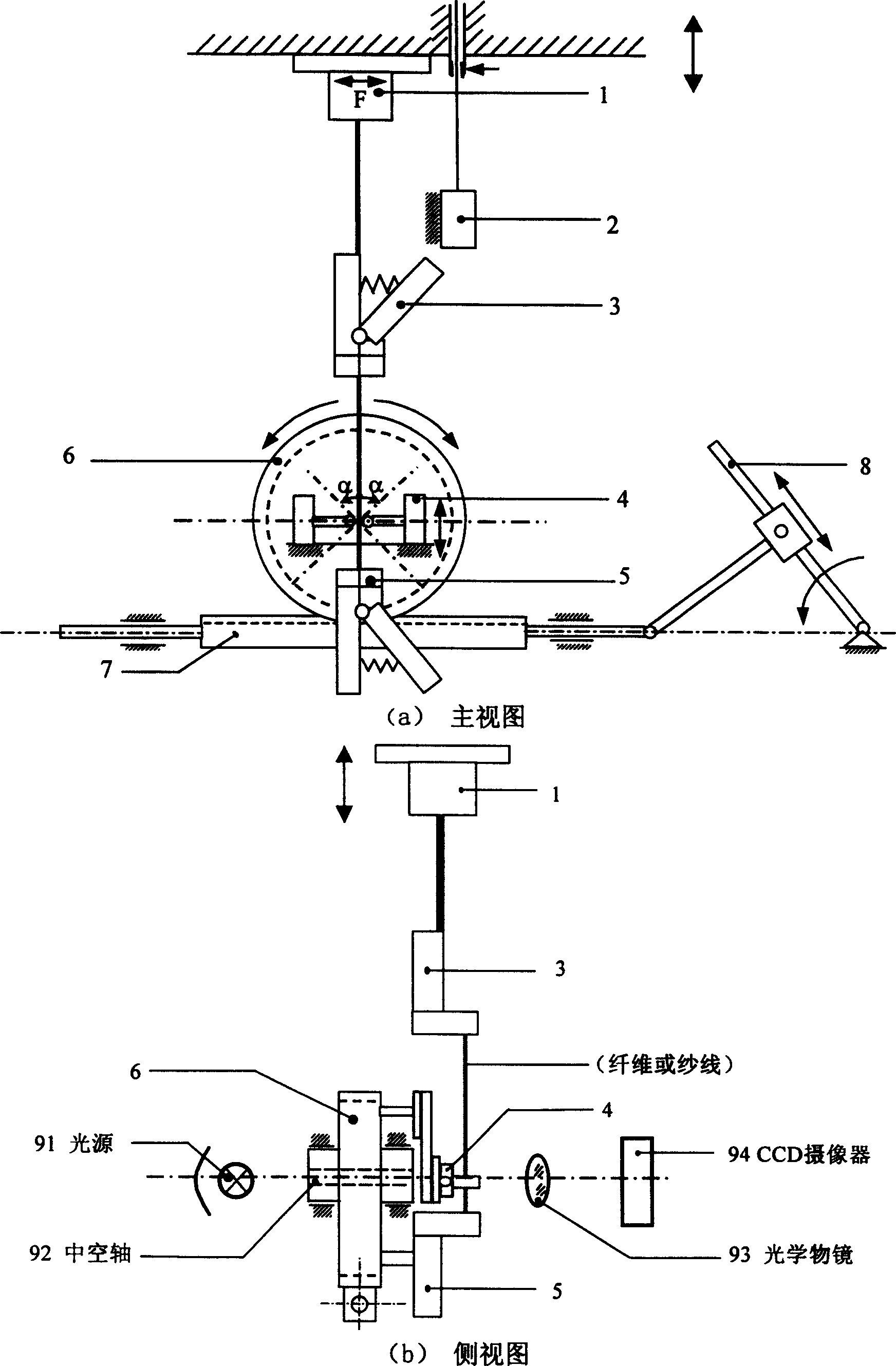

Measuring device for flexural fatigue property of flexible material

A bending fatigue and measuring device technology, applied in the field of fatigue measurement, can solve problems such as unreported measurement technology, and achieve the effect of reasonable function, simple device components, and easy installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

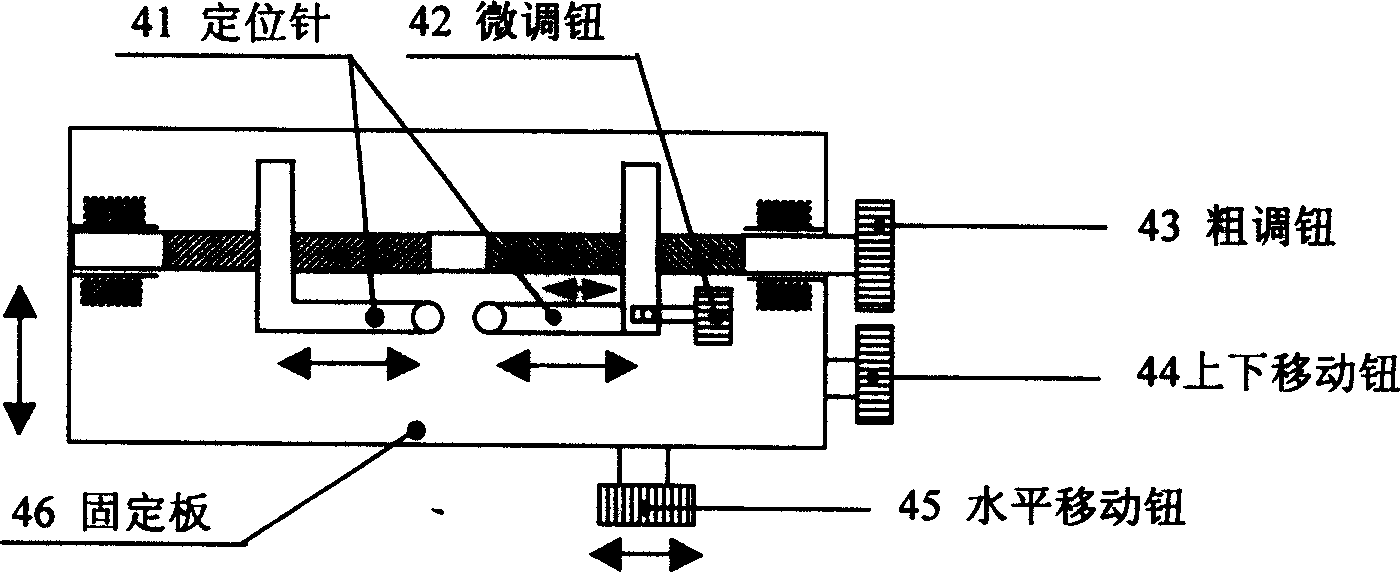

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Fixed load single fiber bending fatigue test results

[0035] The pretension is 3cN / dtex, and the fatigue life test results of aramid (Twaron2000) fibers are:

[0036] Condition Twaron 2000 (1.68dtex) fatigue life (times)

[0037] 35° 3.29cN 9655 9900 10350 9385 10022 8900 8960 9356 8800 9360

[0038] 35° 6.58cN 4630 5780 3300 4345 4160 5740 4980 3089 3015 3020

[0039] 45° 4.93cN 4145 4200 2960 3018 4042 3760 2738 3600 2710 2360

[0040] 55° 3.29cN 1540 1054 1100 1680 1530 1308 1086 2315 2185 1450

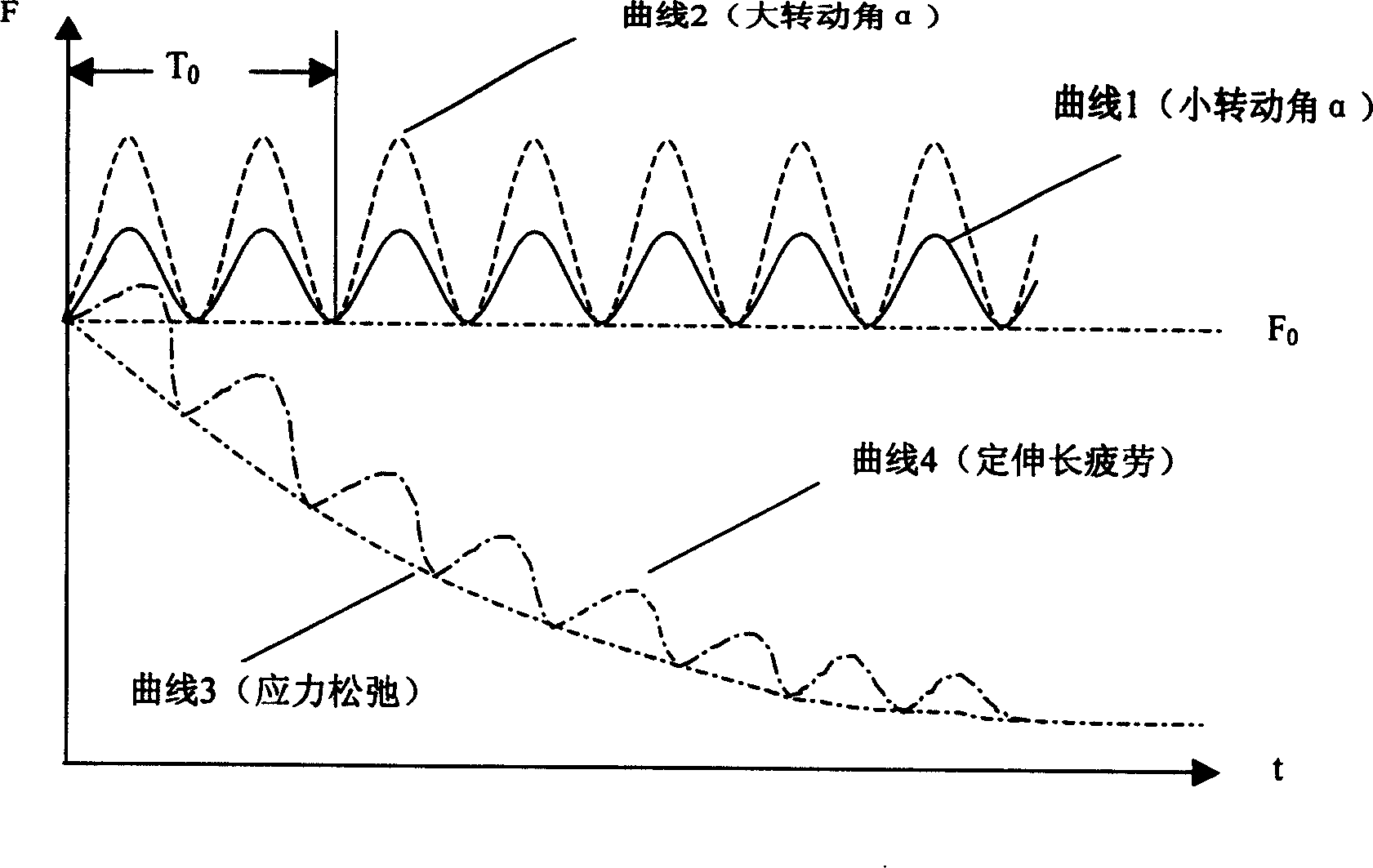

[0041] It can be seen from the above table that under a small specific stress (less than 10% of the specific stress of fiber fracture) and a small rotation angle, the fiber bending fatigue failure does not reach the conventionally used 10%. 5 Fatigue life shows that although aramid fibers have high tensile strength, they have poor resistance to bending fatigue.

Embodiment 2

[0042] Example 2 Relaxation Test of Fibers

[0043] Using the relaxation stress measurement mode, measure the relaxation characteristics of Twaron2000 (1.68dtex):

[0044] condition ε 0 =2%

[0045] Time t(h) 1 2 6 10 14 18 20 24 28 32

[0046] Stress σ(cN) 111.5 106.2 90.2 76.4 64.5 54.7 50.3 42.6 40.2 40.1

[0047] By calculation, at constant elongation ε 0 =2%, the relaxation time τ of the fiber is 23.86h. Because stress relaxation is a tensile characteristic, the fiber has better tensile fatigue resistance properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com