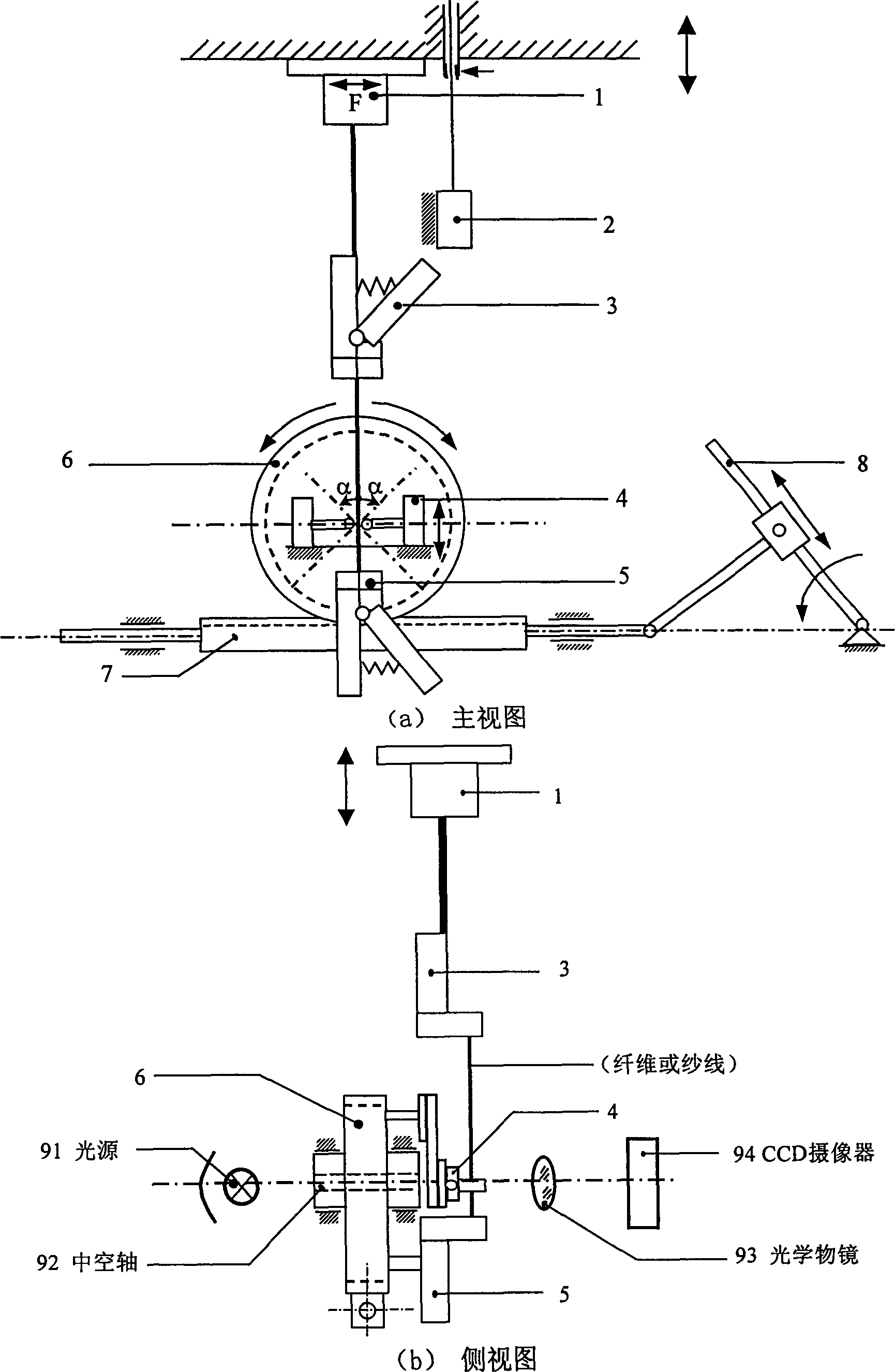

Measuring device for bending fatigue property of flexible material

A bending fatigue and measurement device technology, applied in the field of fatigue measurement, can solve problems such as unreported measurement technology, and achieve the effects of reasonable function, compact structure, and simple device components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

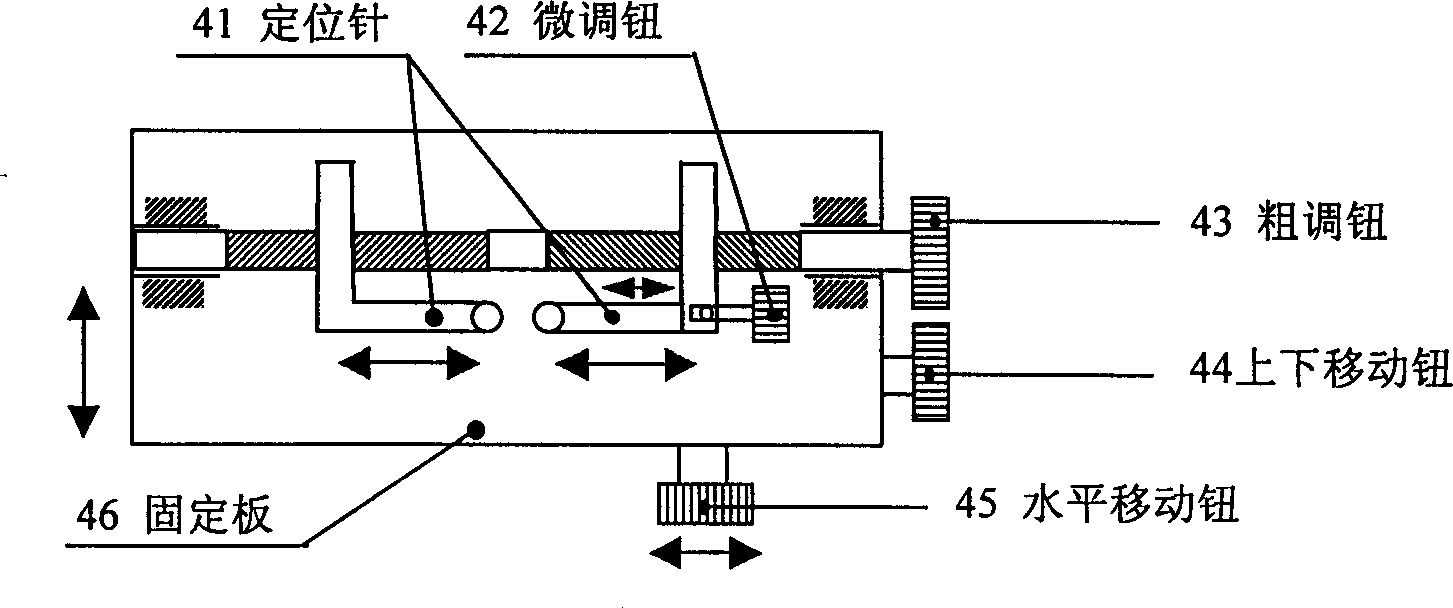

Method used

Image

Examples

Embodiment 1

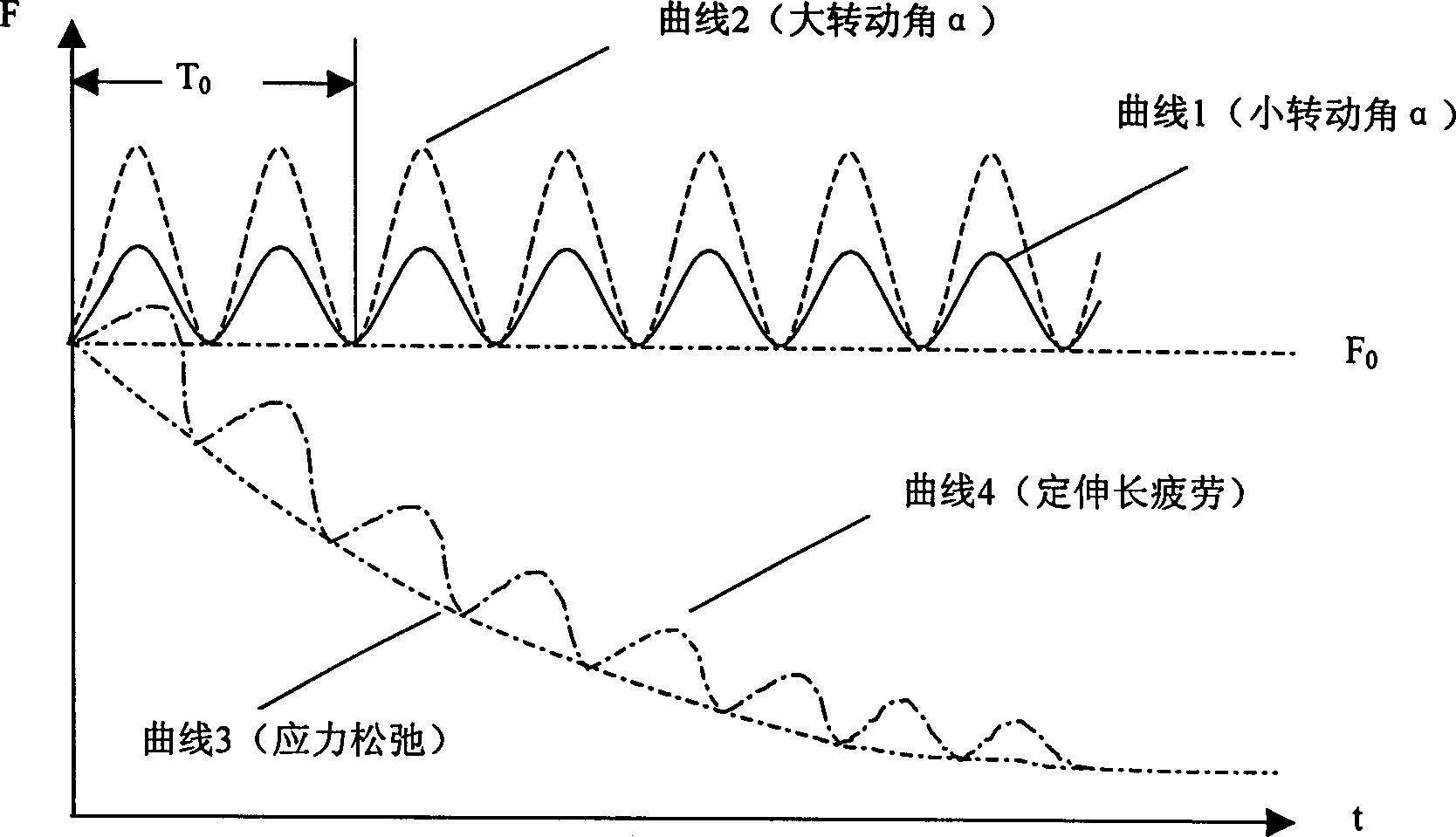

[0038] Example 1 Constant Load Single Fiber Bending Fatigue Test Results

[0039] condition

[0040] It can be seen from the above table that under a small specific stress (less than 10% of the specific stress of fiber fracture) and a small rotation angle, the fiber bending fatigue failure has not reached the conventional use of 10%. 5 Fatigue life, indicating that although aramid fiber has high tensile strength, its resistance to bending fatigue is poor.

Embodiment 2

[0041] Example 2 Relaxation test of fibers

[0042] condition

[0043] By calculation, at a given elongation ε 0 =2%, the relaxation time τ of the fiber is 23.86h. Because the stress relaxation is a tensile characteristic, the fiber has better resistance to tensile fatigue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com