Flexural fatigue testing machine for multi-throw crank shaft

A bending fatigue and testing machine technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve problems such as poor stability, large error in test results, and low work efficiency, and achieve the effects of increasing resonance frequency, convenient operation, and convenient position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

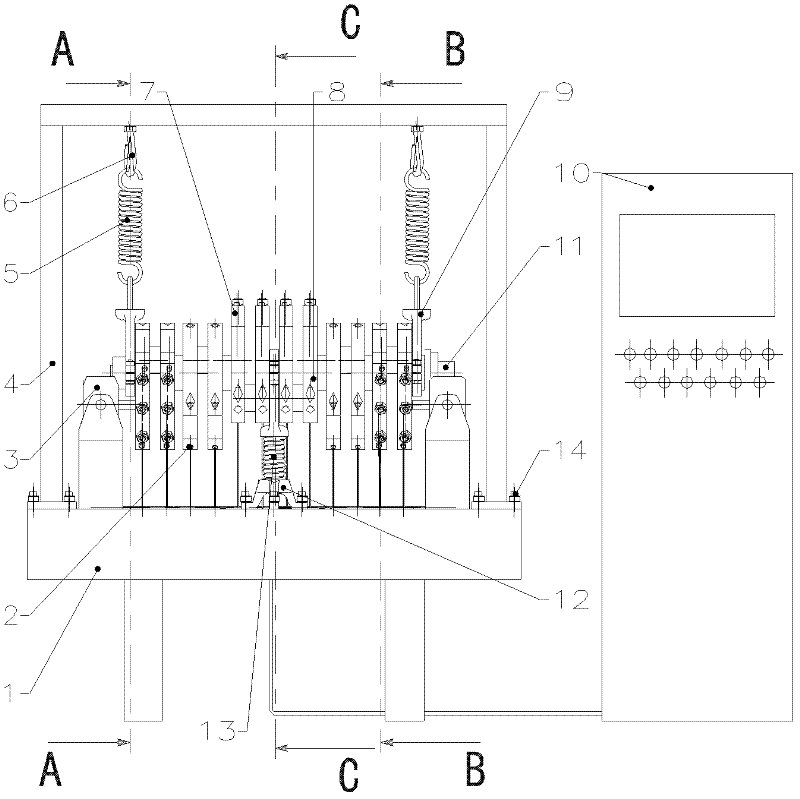

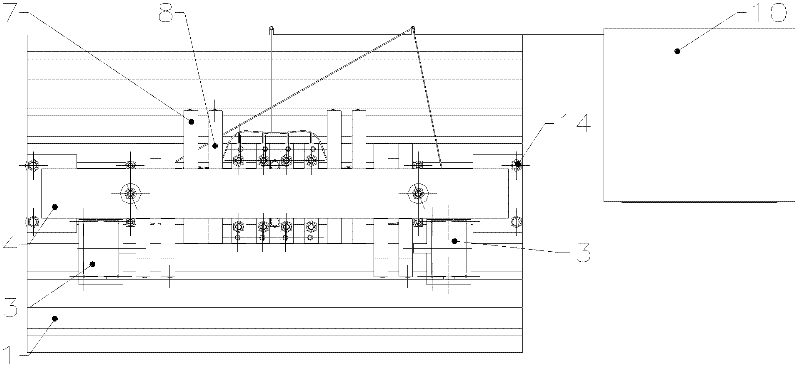

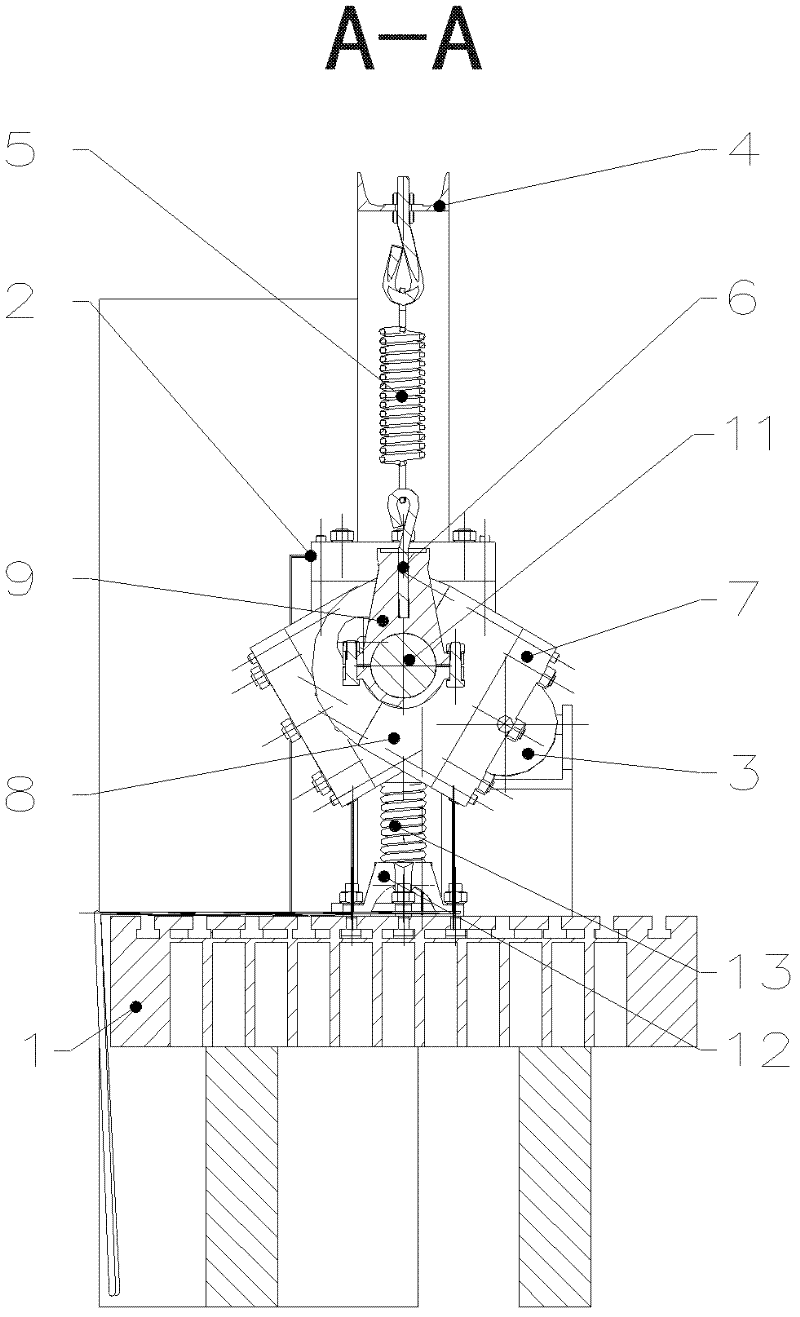

[0024] A kind of multi-turn crankshaft bending fatigue testing machine of the present invention, taking the six-turn crankshaft as an example, its structure is as follows figure 1 As shown, it includes: workbench 1, displacement sensor 2, electromagnetic exciter 3, gantry frame 4, tension spring 5, hook bolt 6, counterweight 7, crank arm clamp body 8, shaft diameter clamp body 9, Signal control and processing system 10, spring support seat 12, compression spring 13 are characterized in that:

[0025] The bottom of the workbench 1 is fixed to the ground through the base, and the upper surface of the workbench 1 is processed with parallel and evenly distributed T-shaped grooves. Two electromagnetic exciters;

[0026] The two hook bolts 6 fixed on the gantry 4 are respectively connected downwards with one end of a tension spring 5 of the same specification, and the other ends of the two tension springs are respectively connected to the two ends of the multi-turn crankshaft 11 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com