Organic rare-earth energizer for chemical heat treatment

A technology of chemical heat treatment and infiltration agent, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of rare earth chloride clogged dropper, complex components of rare earth infiltration agent, high cracking temperature, etc. problems, to achieve the effects of reduced energy consumption, increased infiltration speed, and low cracking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] According to weight percent, methanol is 40wt%, carbon tetrachloride is 56wt% (the volume ratio of methanol and carbon tetrachloride is 1.43), ferrocene is 0.4wt%, and rare earth is 3.6wt% (rare earth and ferrocene The content of ferrocene is 4%, and the content ratio of rare earth and ferrocene is 9), and the above materials are mixed and formulated into a permeation agent. In the rare earth, the rare earth element is a mixture, and the rare earth element is divided into 98wt% Ce, 2wt% % La.

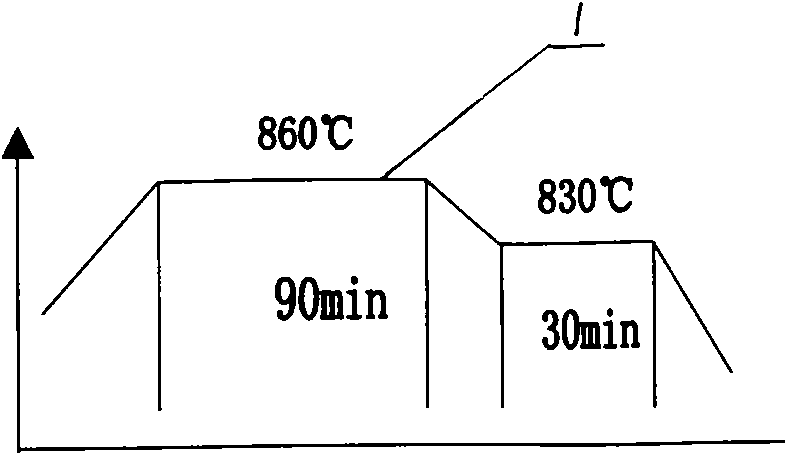

[0037] Dissolve the rare earth infiltration agent in the mixture of kerosene and methanol to ensure that the rare earth content is 1.0%, and use the infusion method to infiltrate at 860°C in the furnace for low-temperature carburizing during the heat treatment of the workpiece. The infiltration results are shown in the table 2. Workpiece heat treatment process conditions:

[0038] Heat treatment equipment: 60kw well type carburizing furnace;

[0039] Heat treatment workpiece: ...

Embodiment 2

[0042] According to weight percent methyl alcohol and the mixture of ethanol 1: 1 are 50wt% altogether, and carbon tetrachloride is 1.0wt% (the volume ratio of alcohols and carbon tetrachloride is 100), and ferrocene is 0.5wt%, and rare earth is 48.5wt% (the content of rare earth and ferrocene is 49%, the content ratio of rare earth and ferrocene is 97), the above-mentioned materials are mixed and formulated into a permeation agent, and the rare earth element used is 75wt% Ce and 25wt% La. The infiltration test is the same as in Example 1, and the infiltration results are shown in Table 2.

Embodiment 3

[0044] According to weight percent methyl alcohol and ethanol mixture are 30wt% altogether, and carbon tetrachloride is 15wt% (the volume ratio of alcohols and carbon tetrachloride is 4), ferrocene is 13wt%, and rare earth is 32wt% (rare earth and The content of ferrocene is 45%, and the content ratio of rare earth to ferrocene is 2.46), and the above materials are mixed and formulated into the infiltration agent. The composition of rare earth elements is shown in Table 1. The infiltration test is the same as in Example 1, and the infiltration results are shown in Table 2.

[0045] Table 1 Rare earth element distribution wt%

[0046] La 2 o 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com