Nitrocarburized microalloyed steel member

A non-quenched and tempered steel, soft nitriding technology, applied in the field of non-quenched and tempered steel parts, can solve the problems of increased cost and prolonged operation time

Inactive Publication Date: 2007-08-01

HONDA MOTOR CO LTD +1

View PDF7 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the past, in order to ensure good bending correction, normalizing treatment (so-called normalization treatment) was performed after hot forging to sizing the steel structure and removing deformation, but due to the addition of normalizing treatment, the operation time was prolonged, resulting in cost. increase

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0113] Hereinafter, the results of experiments conducted to confirm the effects of the present invention will be described.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

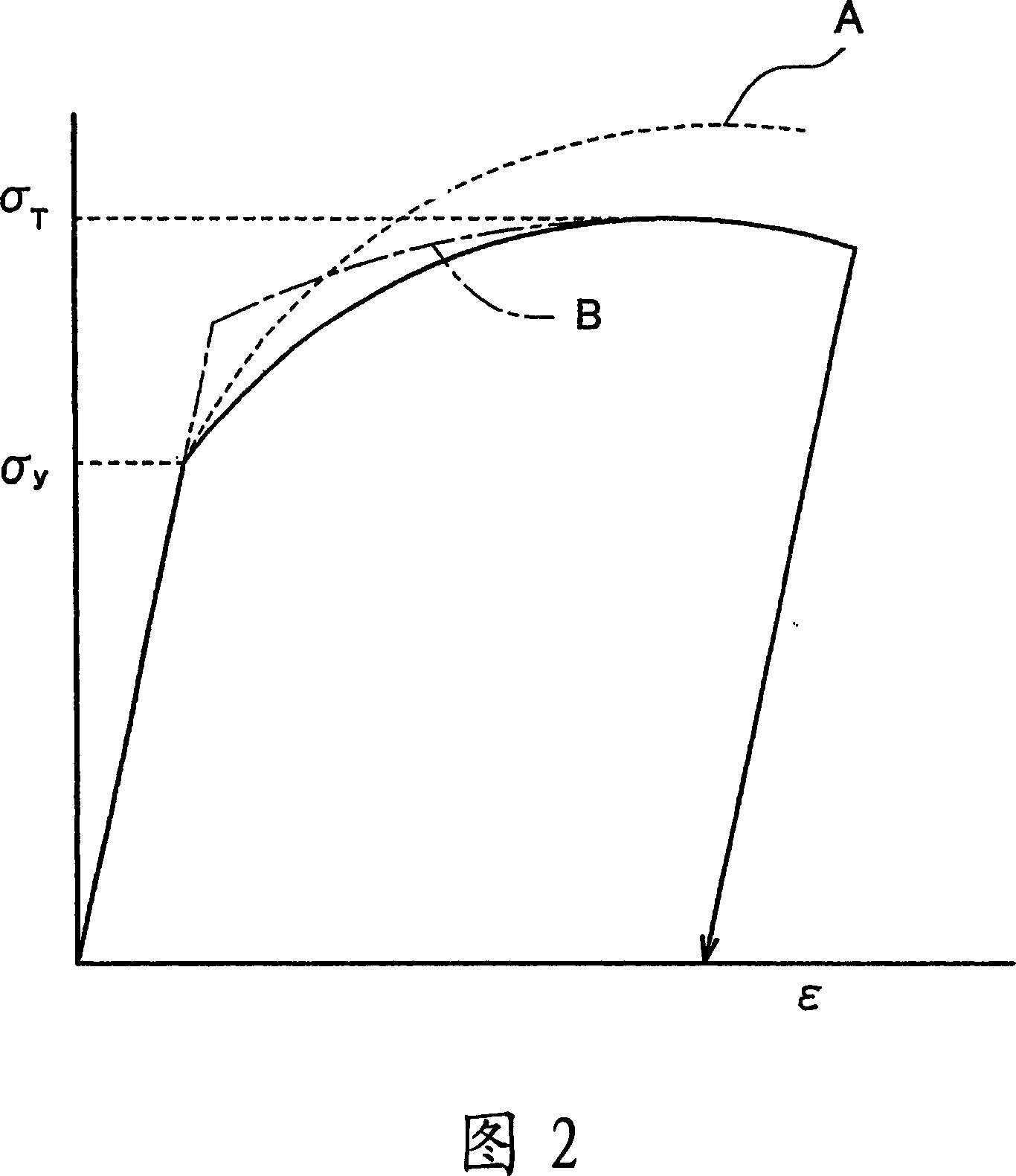

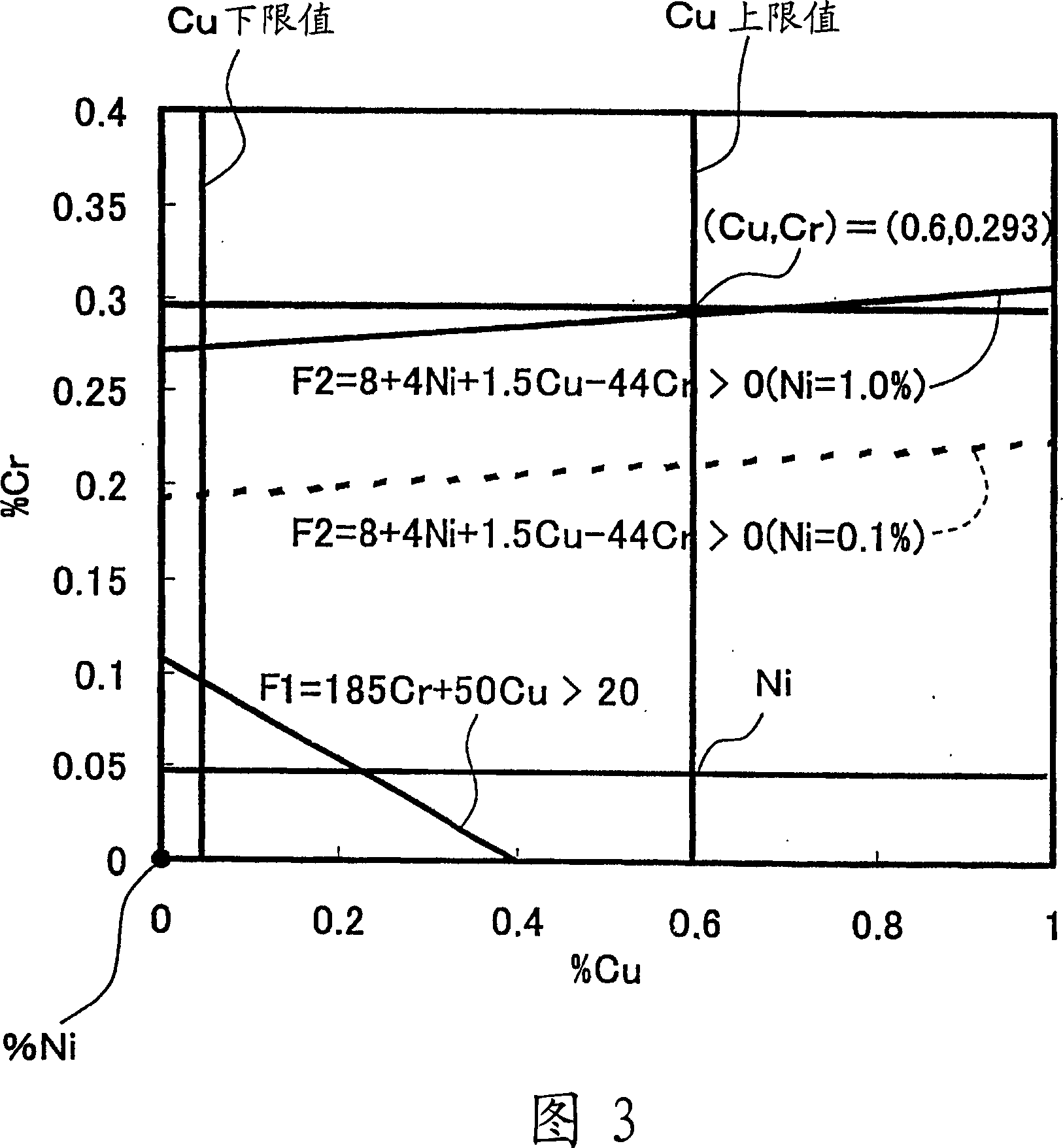

A nitrocarburized microalloyed steel member consists of a microalloyed steel that includes a nitrocarburized layer on a surface, a cross-sectional structure of which steel except for the nitrocarburized layer includes a ferrite and pearlite structure. The microalloyed steel mainly consists of Fe and has a composition: C; Si; Mn; S; Cu; Ni; and Cr having fitting content ranges. If the contents of the Cu, the Ni, and the Cr are represented by WCu, WNi, and WCr mass %, respectively, and composition parameters F1 and F2 are 185WCr+50WCu and 8+4WNi+1.5WCu-44WCr, respectively, then the composition parameters F1 and F2 satisfy F1>20 and F2>0.

Description

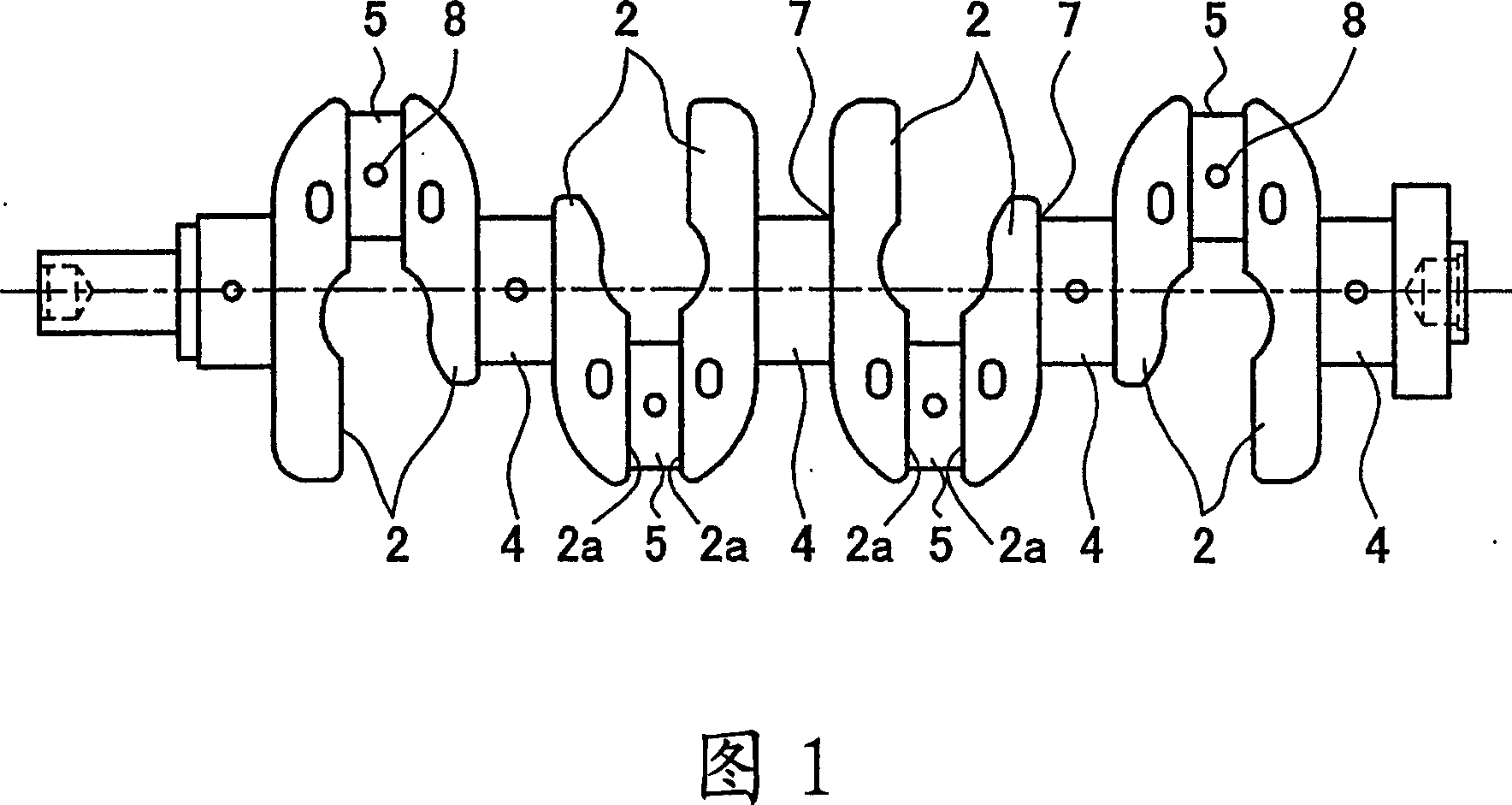

technical field [0001] The present invention relates to a non-quenched and tempered steel part having a nitrocarburized layer formed on the surface. Background technique [0002] [Patent Document 1] Japanese Unexamined Patent Publication No. 09-030632 [0003] [Patent Document 2] Japanese Unexamined Patent Publication No. 06-128690 [0004] [Patent Document 3] Japanese Unexamined Patent Publication No. 05-279795 [0005] [Patent Document 4] Japanese Unexamined Patent Publication No. 05-279794 [0006] [Patent Document 5] Japanese Unexamined Patent Publication No. 09-324258 [0007] [Patent Document 6] JP-A-2002-226939 [0008] [Patent Document 7] JP-A-2005-264270 [0009] Since crankshafts for vehicles are used in an environment where large torsional loads and bending loads are repeatedly applied, excellent static strength and fatigue strength are required. On the other hand, since it is a large and complex-shaped component, it is generally manufactured from non-quench...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/42C22C38/44C21D11/00

CPCC23C8/32F16C2204/64C22C38/002C22C38/42C22C38/50C22C38/60C22C38/001C22C38/02F16C3/08C22C38/04

Inventor 浅井铁也泷谷善弘天野政树保母诚木村和良高田胜典

Owner HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com