Three-point and four-point flexural fatigue general test fixture for composite material

A composite material, four-point bending technology, applied in the direction of analyzing materials, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further describe the present invention below in conjunction with example and accompanying drawing.

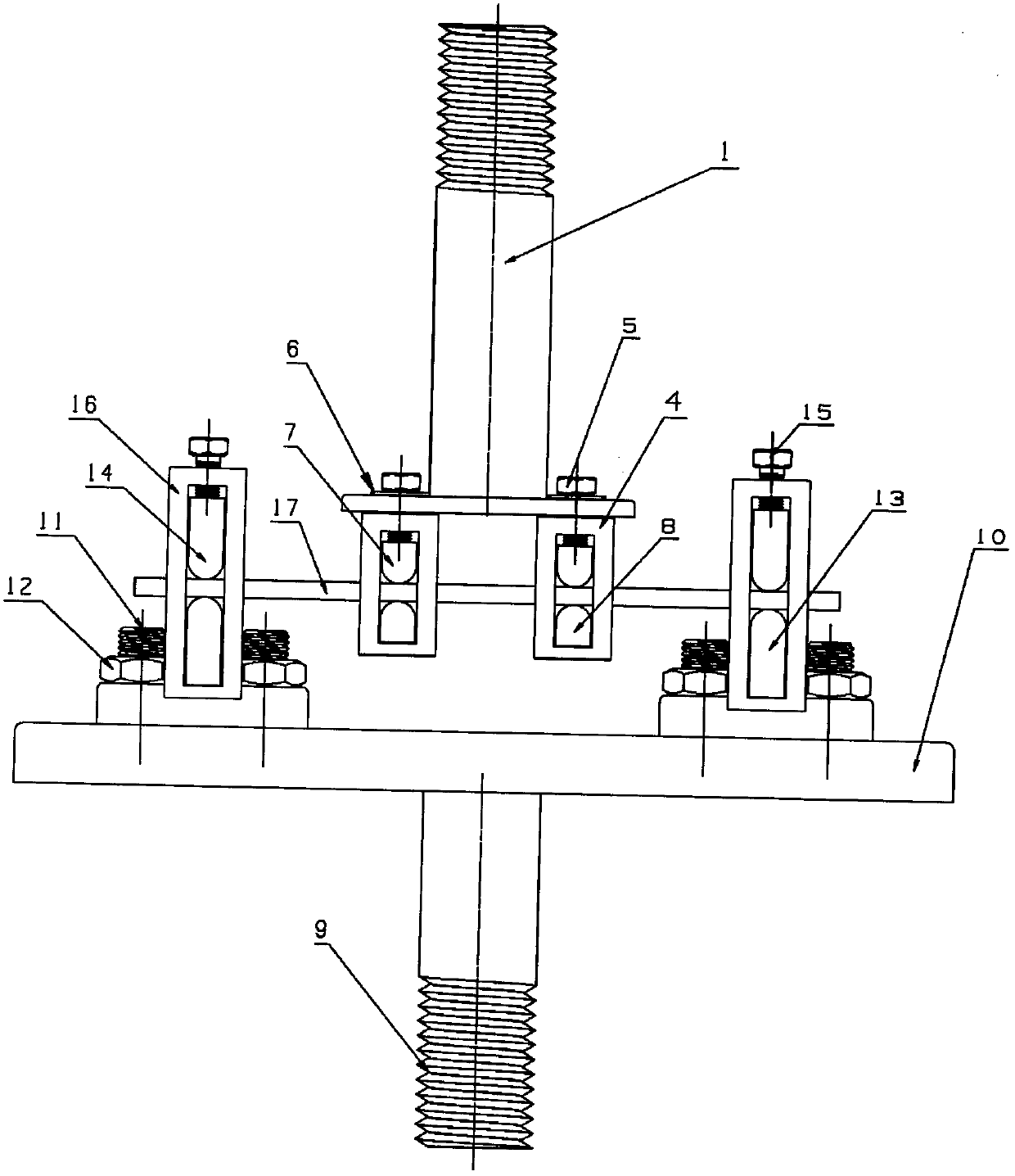

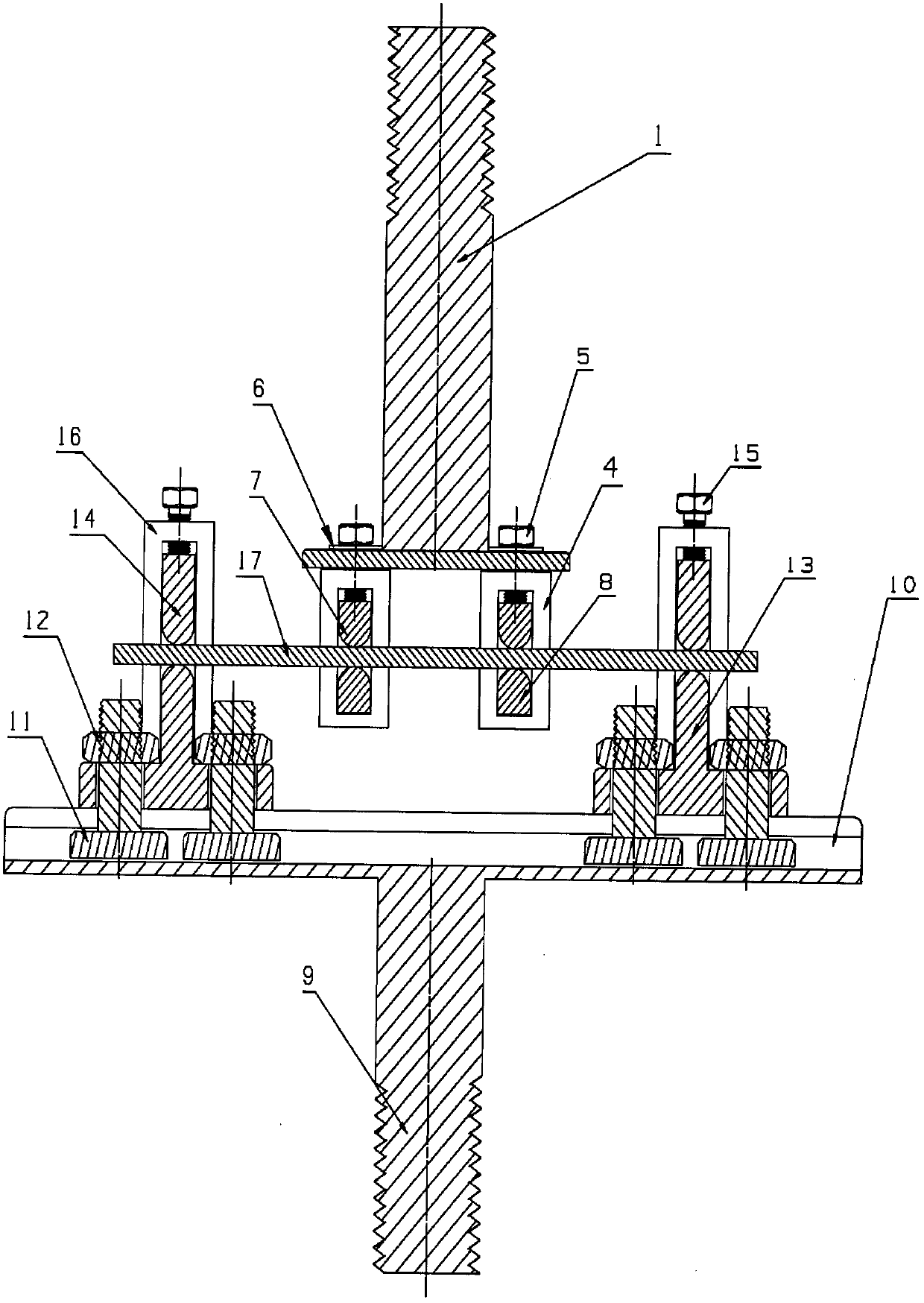

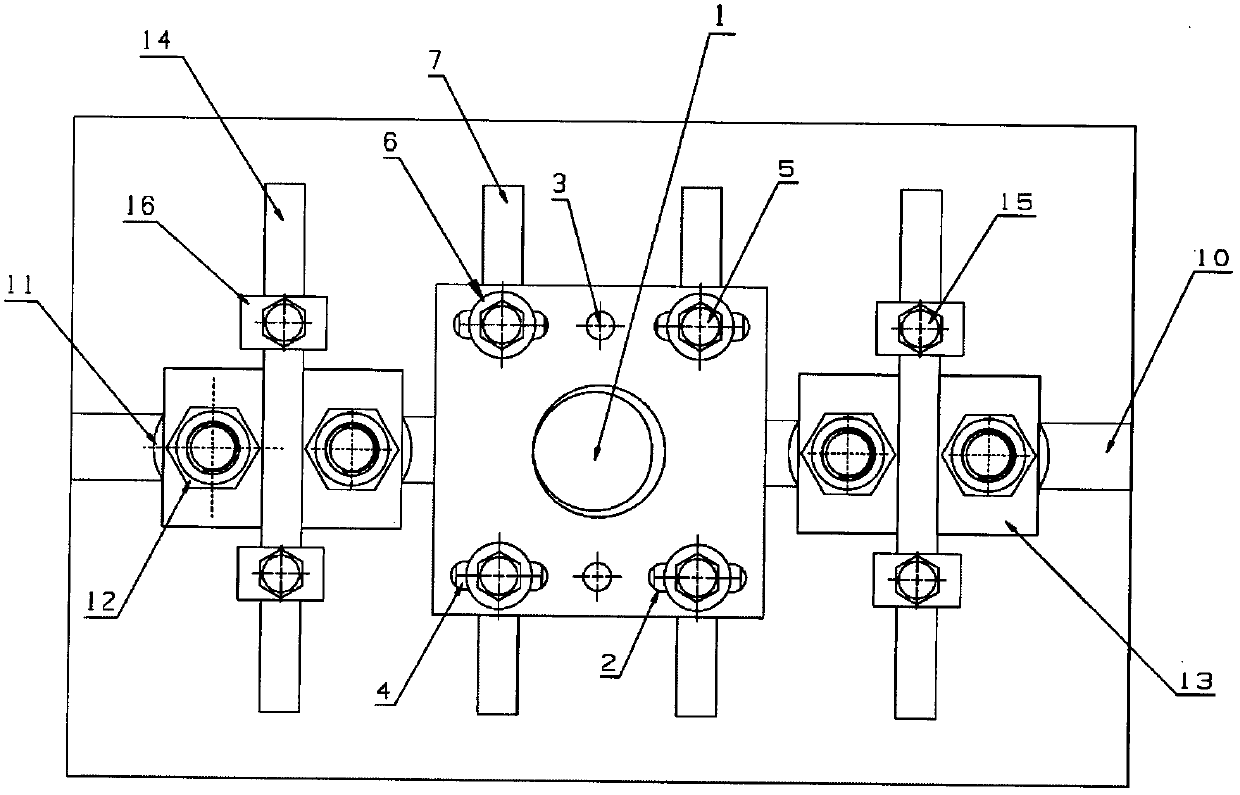

[0016] A general test fixture for three-point and four-point bending fatigue of composite materials, including a loading part and a supporting part, such as figure 1 and image 3 shown. The loading part includes: loading part panel (screw 1, round head rectangular slot 2, screw hole 3), rectangular hollow square iron 4, screw 5, gasket 6, upper chuck 7, lower chuck 8. The supporting part includes: supporting part bottom plate (stud 9, T-shaped guide rail 10), screw 11, nut 12, base 13, clamping beam 14, screw 15, rectangular hollow square iron 16, sample 17.

[0017] Before the experiment, connect the stud 1 with the screw hole at the loading end of the fatigue testing machine, and connect the stud 9 with the screw hole at the support end of the fatigue testing machine. Then put the strip sample 17 between the upper chuck 7 and the lower chuck 8 of the loading part, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com