Friction transmission belt

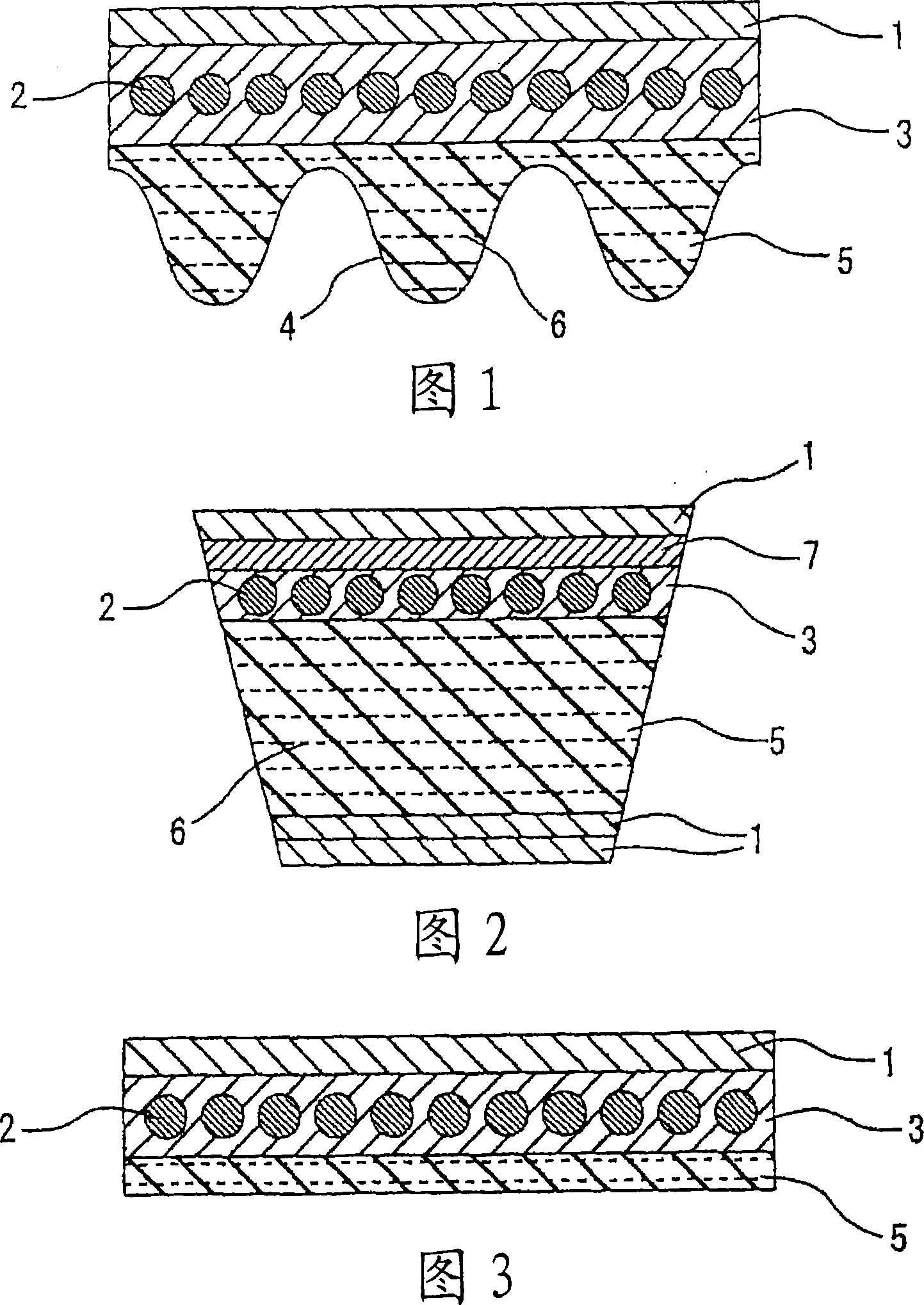

A friction drive belt, V-ribbed belt technology, applied in the direction of drive belts, V-belts, belts/chains/gears, etc., can solve problems such as unresearched in detail, achieve excellent bending fatigue, suppress the generation of sliding noise, and suppress sliding noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5、 comparative example 1

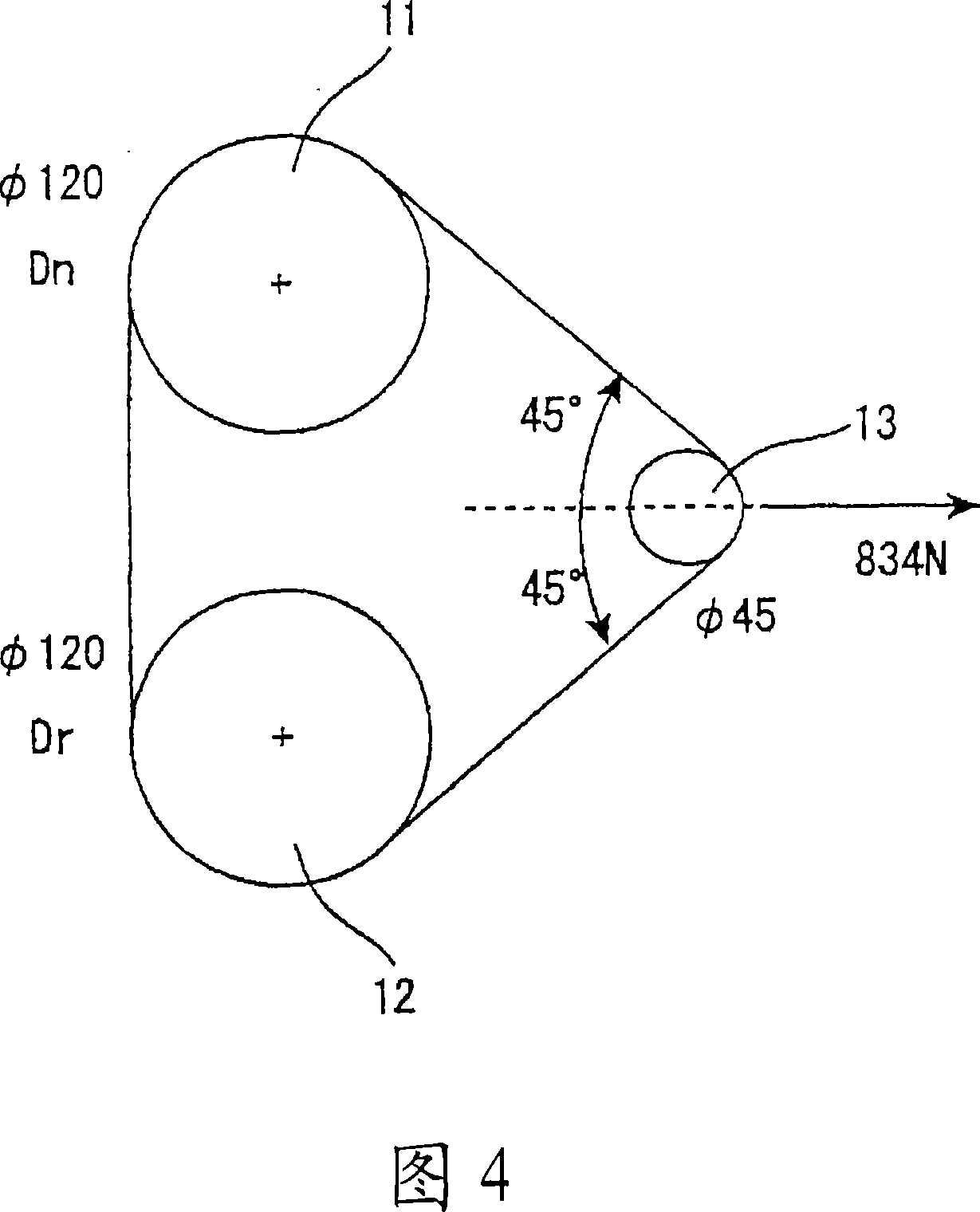

[0065] (Examples 1-5, Comparative Example 1, Comparative Example 2)

[0066] First, a rubber compound unvulcanized sheet for a compression rubber layer having a compound composition shown in Table 1 was manufactured. The values of the mixed compositions in Table 1 are shown in "parts by mass". In addition, the commercially available items used are as follows.

[0067] Ethylene-propylene-diene rubber (EPDM):

[0068] Nordel IP 4640 (55% ethylene content, diene ENB, manufactured by DuPont Dow Elastomers)

[0069] Chloroprene rubber (CR): Neoprene GRT (sulfur-modified chloroprene rubber, manufactured by DuPont Dow Elastomers)

[0070] Carbon black: HAF carbon (manufactured by Mitsubishi Chemical Corporation)

[0071] Silica: Tokusil GU (made by Tokuyama Corporation)

[0072] Silane coupling agent: Si-69 (manufactured by Degussa Corporation)

[0073] Softener: Sunflex 2280 (paraffin oil, manufactured by Japan SUN Chemical Company)

[0074] A vulcanization aid: Stearic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com